Noise is a serious problem in the lives of the youngest residents of homes. Excessive decibel levels disrupt nighttime peace and hinder the body’s recovery. Polyurethane acoustic foams offer a solution that can significantly improve the acoustic comfort of children’s spaces. These materials effectively absorb sound waves and reduce reverberation.

Scientific research confirms the negative impact of excessive noise on children’s sleep. Sound levels exceeding 55 dB are considered harmful to health. Polyurethane foams effectively reduce noise intensity by 30-40 dB. The open-cell structure of the material converts acoustic energy into heat. This process occurs through the friction of air molecules against the walls of microscopic channels inside the foam.

Parents seeking a quieter environment for their children’s rest find polyurethane acoustic foams a practical tool. This material combines effectiveness with safety for use in children’s rooms.

How polyurethane acoustic foams contribute to noise reduction in children’s environments

The space of a child’s room requires special attention to acoustics. Excessive noise disrupts play, learning, and rest. Polyurethane acoustic foams reduce unwanted sounds coming from both outside and inside the room. The material’s structure absorbs sound waves instead of reflecting them.

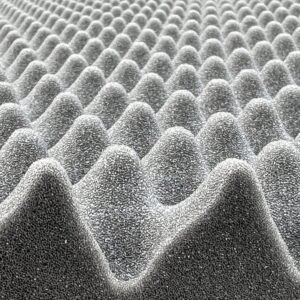

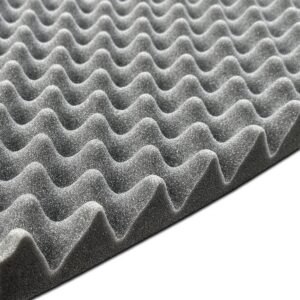

The effectiveness of the foam depends on several parameters. The thickness of the layer determines the range of frequencies that the material effectively dampens. Foam density affects its ability to absorb different types of sounds. The surface shape increases or decreases the area for absorbing acoustic energy.

Using foams in children’s spaces brings measurable benefits. Reducing noise levels positively affects the child’s well-being. A quieter environment promotes better concentration during play and learning. Reducing unwanted sounds improves the quality of nighttime sleep and daytime naps.

The mechanism of sound wave absorption by open-cell structure

Polyurethane foams have a unique cellular structure. Numerous interconnected pores filled with air create a labyrinth of microscopic channels. Sound waves penetrate deep into the material instead of reflecting off its surface. Air molecules vibrate inside the pores under the influence of acoustic energy.

The friction between air and cell walls dissipates sound energy. Part of this energy is converted into heat. The energy dissipation process occurs continuously as waves pass through the foam’s structure. The sound absorption coefficient for polyurethane foam reaches values of 0.9-0.95 for certain frequencies.

The size of pores determines effectiveness in absorbing different tones. Larger cells handle low frequencies better, while finer pores more effectively dampen high sounds. The flexibility of polyurethane’s structure further enhances its ability to absorb acoustic energy.

Air viscosity plays a key role in the damping process. The resistance encountered by particles as they move through narrow channels generates additional energy losses. This mechanism is especially noticeable in foams with small pores. The material’s structure also vibrates under the influence of sound waves, causing further energy dissipation.

Effectiveness of damping different frequency ranges in residential rooms

Sounds surrounding children have a varied frequency character. Low tones come from street traffic and appliance operation. Medium frequencies are generated by conversations and television. High sounds are produced by toys and some household appliances.

Polyurethane foams show varying effectiveness across different ranges. High frequencies above 2000 Hz are absorbed even by thin layers of material 2-5 cm thick. Foams dampen mid-tones in the 250-2000 Hz range most effectively. The absorption coefficient reaches nearly 100% at frequencies of 1000-4000 Hz.

Low frequencies below 250 Hz pose the greatest challenge. Long sound waves require thicker foam layers. The minimum effective thickness for bass is about 10 cm. Special panels mounted in room corners increase control over low tones.

Damping efficiency depending on frequency:

- High tones above 2000 Hz – very high effectiveness at thicknesses of 2-5 cm

- Medium frequencies 250-2000 Hz – almost complete absorption at standard thicknesses

- Low tones below 250 Hz – require thicker layers over 10 cm

- A combination of different thicknesses provides comprehensive acoustic protection

Selecting the appropriate foam thickness for a children’s room depends on noise sources. Apartments near busy streets require thicker layers. Rooms in quiet neighborhoods need thinner material applications.

Reducing reverberation and echo in play and study spaces

Reverberation and echo disrupt sound clarity in a room. Acoustic waves reflect multiple times off hard surfaces. This phenomenon hinders speech comprehension and concentration. Acoustic foams effectively eliminate unwanted sound reflections.

The profiled structure of foams increases the absorbing surface area. Pyramids and waves scatter sound at various angles. Acoustic energy penetrates the material instead of reflecting back into the room. Reverberation time is significantly shortened after applying foams.

Installing acoustic panels in strategic locations yields the best results. First reflection points on walls require foam coverage. The ceiling above play and study areas also needs acoustic adaptation. Distributing material over 20-30% of wall and ceiling surfaces is sufficient in most cases.

Reducing reverberation positively affects a child’s language development. Clearer speech sounds facilitate communication learning. Cleaner music and story sounds support auditory development. Echo reduction improves comfort during loud play and physical activities.

Placing acoustic foams in room corners effectively controls low frequencies and reduces standing waves, which can cause uneven sound distribution in children’s spaces.

Safety of Polyurethane Materials in Contact with the Youngest Household Members

Children’s health is the highest priority when choosing finishing materials. Polyurethane foams used in the youngest children’s rooms must meet strict safety standards. Manufacturers subject materials to detailed toxicological tests. Certificates confirm the absence of harmful substances in the foam composition.

Contact of a child’s skin with the foam surface should not cause allergic reactions. The material must not emit volatile organic compounds at concentrations exceeding permissible limits. The foam’s mechanical resistance protects against damage during daily use.

Parents should verify product documentation before purchase. Hygiene certificates guarantee safety for use in living spaces. Quality certificates confirm compliance with Polish and European regulations.

Hygiene Certificates and Approvals for Products Used in Children’s Rooms

The PZH Hygiene Approval confirms the safety of materials in various environments. The National Institute of Public Health conducts detailed testing of foam samples. Tests include analysis of emissions of potentially harmful substances. This certificate is a fundamental verification document for products used in residential spaces.

The RoHS Certificate guarantees the absence of hazardous substances in the material composition. Foam manufacturers must prove that products do not contain lead, cadmium, or other heavy metals. This standard protects both users’ health and the natural environment.

Certificates of compliance with PN-EN standards confirm meeting European quality standards. The PN-EN 14315-1 standard specifies requirements for insulation foams. The ETA declaration presents a technical assessment of the construction product. Tests conducted in accredited laboratories document material properties.

Key Safety Certificates:

- PZH Hygiene Approval – confirmation of safe use

- RoHS Certificate – guarantee of no harmful substances

- ISO 9001 Certificate – manufacturer’s quality management system

- Acoustic tests – documentation of sound absorption properties

- Fire reaction certificates – resistance to high temperatures

Specialty stores such as ABM Insulation provide full product documentation. Customers can verify certificates before making a purchase. Detailed technical documents contain information about foam composition and properties.

Antiallergenic and Nontoxic Properties of Acoustic Foams

Emission of volatile organic compounds is a key safety parameter. The VOC certificate confirms low VOC emission values. High-quality foams release minimal amounts of volatile substances into the air. Emission levels drop significantly after several days of room ventilation.

The Greenguard certificate includes detailed analysis of formaldehyde and aldehydes. This standard especially protects children and allergy sufferers. Products marked with this certificate maintain low emissions throughout their lifecycle. Verification also covers flame retardants added to foams.

High-quality polyurethane foams do not contain contact allergens. The material’s surface does not promote the growth of house dust mites. The open-cell structure allows air circulation through the material. Periodic vacuuming of the foams removes settled dust and maintains hygiene.

Manufacturers use non-toxic pigments to color the foams. The colors do not migrate to other surfaces upon contact. The material does not emit unpleasant odors after ventilation is complete. Toxicological certificates document no impact on users’ health.

Resistance to deformation and long-lasting material elasticity

Polyurethane foams retain their properties for many years of use. The material returns to its original shape after pressure is released. The elasticity of the cellular structure ensures mechanical durability. High-quality polyurethane guarantees resistance to plastic deformation.

Foam density directly affects its durability. Materials with a density of 20-30 kg/m³ provide adequate strength for household applications. High-density foams at 140 kg/m³ exhibit even greater resistance to damage. The cellular structure does not degrade during normal use.

Moisture resistance is another important feature of polyurethane foams. The material does not absorb water and does not promote mold growth. Periodic cleaning of the foams with a damp cloth does not affect their properties. Quick drying prevents moisture accumulation inside the structure.

Proper maintenance extends the lifespan of acoustic foams. Avoiding direct exposure to sunlight prevents material degradation. Regular vacuuming keeps the surface clean. Foams installed according to manufacturer recommendations maintain effectiveness for decades.

Protection against mechanical injuries during daily activities

The soft surface of polyurethane foams provides a safe solution for active children. The material cushions impacts during play and accidental falls. The flexible structure absorbs mechanical energy without stiff rebound. Rounded shapes of pyramid and wave profiles eliminate sharp edges.

Installing foams on lower wall sections protects a child’s head during learning to walk. Covering room corners with soft material increases play safety. Foams do not contain hard elements that could cause cuts. The material’s surface does not irritate skin upon contact.

Stable foam mounting prevents detachment and hazard creation. Self-adhesive layers ensure a durable bond with the wall surface. Additional mechanical fastening increases safety in heavily used spaces. Foams do not release fine particles that could enter respiratory tracts.

The colors of acoustic foams contain no toxic substances. Abrasion-resistant dyes do not transfer onto a child’s hands. The material’s surface is easy to keep clean. Regular cleaning removes dirt without degrading the foam structure.

Tip: Choosing foams with the Greenguard certification guarantees minimal emission of volatile organic compounds throughout the entire usage period, which particularly protects the respiratory system of developing children.

The Relationship Between Room Acoustic Quality and Nighttime Recovery of Young Children

Sleep is a fundamental regenerative process for a child’s body. The quality of nighttime rest directly affects physical and mental development. The acoustic conditions of the room determine the depth and continuity of sleep. Excessive noise disrupts natural sleep cycles and awakens the child.

An environment with low noise levels promotes faster falling asleep. Silence allows passage through all sleep stages. Deep slow-wave sleep is responsible for cell regeneration and body growth. The REM phase supports nervous system development and memory consolidation.

Scientific studies document the negative impact of noise on children’s health. Sound levels exceeding 55 dB are considered harmful. Prolonged exposure to noise leads to sleep disturbances and behavioral problems. Improving the acoustics of a child’s room is an investment in their health.

The Impact of Excessive Decibel Levels on Children’s Sleep Microstructure

Sleep microstructure includes detailed stages of rest cycles. Excessive noise disrupts smooth transitions between phases. Sounds above 45 dB during the night cause sleep fragmentation. The child wakes up more frequently, although not always fully regaining consciousness.

The deep slow-wave sleep phase shrinks under noise influence. The body spends more time in lighter sleep stages. Shortening deep sleep limits growth hormone secretion. The tissue regeneration process and immune system function weaken.

The REM phase also experiences disturbances in noisy environments. The brain cannot effectively process information acquired during the day. Memory consolidation and learning are impaired. Children exposed to nighttime noise show difficulties concentrating and remembering.

Cortisol levels increase due to acoustic stress. This hormone activates the body and makes maintaining a restful state difficult. Chronic acoustic stress leads to hormonal imbalance disorders. Studies show a link between nighttime noise and developmental problems.

Reduction of Nighttime Awakenings in an Environment with Improved Acoustics

The use of acoustic foams significantly reduces the number of nighttime awakenings. The material absorbs external and internal sounds that disrupt sleep. Noise reduction by 30-40 dB creates a calm environment for rest. The child sleeps through the night without interrupting sleep cycles.

Research on infant sleep safety devices confirms the effectiveness of acoustic panels. An experiment with 30 trials without soundproofing and 30 with panels showed significant differences. Noise levels dropped below the recommended limit of 50 dB. A statistical result with a p-value below 0.001 confirms significant effectiveness.

A quieter environment allows natural awakenings between sleep cycles. The child smoothly transitions to the next phase without full awakening. Lack of external disturbances enables self-soothing and falling back asleep naturally. Parents observe less frequent waking and better morning well-being.

Benefits of Improved Nighttime Acoustics:

- Reduction of the number of awakenings by over 50%

- Extension of deep restorative sleep phases

- Easier falling asleep in the evening and after nighttime awakenings

- Better mood and well-being of the child during the day

- Calmer sleep for parents due to fewer interventions

Sleep quality also improves during daytime naps. Acoustic foams dampen noises from other rooms and outside. The child can rest even during the activities of other household members. Regular naps support development and improve well-being.

The Role of Silence in Cognitive Development and Concentration of Young Room Users

The cognitive development of a child requires appropriate acoustic conditions. Silence enables focusing attention on tasks and educational play. Excessive background noise distracts attention and reduces learning efficiency. The brain is forced to filter unwanted sounds at the expense of cognitive resources.

Scientific studies show a connection between noise and children’s cognitive functions. Exposure to sound levels above 55 dB worsens memory test results. Children from noisy environments exhibit difficulties in speech comprehension. Reaction time and problem-solving abilities are weakened.

Improving the acoustics of a child’s room supports language development. Clear speech sounds without disturbances facilitate communication learning. The child better distinguishes phonemes and builds vocabulary. Loud reading by parents becomes more effective.

Concentration during learning requires an environment with controlled acoustics. Polyurethane foams reduce noise from outside and reverberation inside the room. The child can focus on tasks without constant disturbances. The quality of homework and time spent on creative activities increases.

Children’s mental health also benefits from a quieter environment. Chronic acoustic stress leads to irritability and behavioral problems. A calm environment promotes emotional balance. Children show fewer anxiety symptoms and better emotion regulation.

Tip: Covering 20-30% of wall surfaces with acoustic foams is sufficient for significant acoustic improvement without excessive sound dampening, preserving the natural sound comfort of the child’s space.

Installation and Placement of Soundproofing Elements in Children’s Spaces

The effectiveness of acoustic foams depends not only on their properties but also on proper installation. Strategic placement of panels maximizes noise reduction effects. Installation does not require specialized tools or construction skills. Parents can install foams themselves in the child’s room.

Surface preparation is a key stage in the process. Walls must be clean, dry, and free from grease. Dust and dirt weaken the adhesion of the self-adhesive layer. Thorough preparation guarantees durable panel mounting.

Planning foam placement precedes actual installation. Identifying noise sources helps determine optimal panel locations. Visualizing element distribution ensures an aesthetic appearance of the room. Combining functionality and aesthetics creates a friendly space for the child.

Optimal Panel Locations Relative to External Noise Sources

The exterior wall is the main path for street noise penetration. Installing thicker foam on this wall brings the greatest benefits. Covering 30% to 50% of the surface effectively reduces outside sounds. Concentrating panels around the window further strengthens the acoustic barrier.

Windows allow most external noise to pass through. Acoustic foams installed around the window opening create additional protection. Thick curtains or acoustic blinds complement the foam’s effect. Combining different solutions provides comprehensive insulation from street noise.

The wall adjacent to noisy rooms requires special attention. A living room with a TV or kitchen generates sounds that disturb a child’s sleep. Installing foam on the children’s room side dampens noise propagation. A layer thickness of 3-5 cm is sufficient in most cases.

Strategic installation points:

- Exterior wall facing the street – thickness 5-10 cm

- Area around the window – additional protective layer

- Wall adjoining living spaces – thickness 3-5 cm

- Ceiling under the apartment above – protection against footstep noise

- Room corners – control of low frequencies

Apartments on higher floors require foam installation on the ceiling. Footstep noise from the apartment above disrupts a child’s sleep. Acoustic foams absorb impact sounds and reduce their intensity. Combining foam with butyl mat provides even better insulation.

Installation Methods Without Permanent Wall Surface Damage

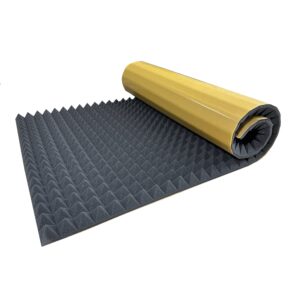

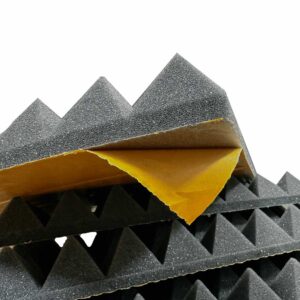

Self-adhesive foams allow installation without drilling holes. The glue layer on the panel’s underside ensures a strong bond. Removing the protective film and pressing the foam to the wall takes seconds. This method is ideal for rented apartments.

Preparing the surface before installation increases adhesion. Washing the wall with a mild detergent removes grease and dust. Drying the surface with a microfiber cloth eliminates moisture. Waiting a few minutes before installation guarantees optimal conditions.

Foams without a self-adhesive layer require additional glue application. Acrylic or mounting adhesives designed for polyurethane foams provide durable attachment. Applying glue in spots or strips saves material. Pressing the foam for several seconds enables glue bonding.

Double-sided mounting tapes are an alternative to adhesives. Flexible 3M VHB tapes provide strong bonds without adhesive mass. Installation is quick and clean. Removing foams leaves minimal marks on the wall.

Aluminum profile systems enable installation without direct gluing to the wall. A lightweight frame mounted at several points holds acoustic panels. This solution facilitates foam replacement and repositioning. The profile leaves small holes easy to fill.

Selecting Thickness and Profile Shape According to Room Specifics

The size of the children’s room influences foam thickness choice. Small rooms under 10 m² require thinner layers of 2-3 cm. Thicker foams would reduce room volume. Focusing on high and mid frequencies yields the best results.

Large rooms over 15 m² can accommodate thicker foams of 5-10 cm. Low-frequency control becomes possible with greater thickness. The long reverberation time in large spaces requires a larger absorbing surface. Covering 30% of the wall area guarantees optimal acoustics.

The shape of the profile affects effectiveness and aesthetics. Pyramid foams effectively disperse sound at various angles. A pyramid height of 5 cm provides good absorption of mid and high tones. The geometric pattern adds an interesting visual element to the room.

Wavy foams create a soft, friendly appearance. Regular waves effectively absorb high frequencies. A thickness of 3-4 cm is sufficient for most home applications. The ability to cut foams allows adaptation to unusual shapes.

Smooth foams present a minimalist solution. The flat surface easily integrates into modern interiors. Availability in various colors allows matching to decor. Color combinations create attractive compositions on walls.

Tip: Installing acoustic foams in room corners at a height of 20-30 cm from the floor and ceiling creates effective bass traps, efficiently controlling low frequencies without significant loss of usable space.

Foams, acoustic panels absorbing sound at the ABM Insulation store

The modern world is full of constant noise that threatens peace and comfort. Sound-absorbing acoustic foams have proven to be an extremely effective solution in reducing unwanted sounds. These materials work by absorbing acoustic energy instead of reflecting it. The open-cell structure enables the transformation of sound waves into heat through air particle friction.

The ABM Insulation store offers a wide selection of acoustic foams with varied technical parameters. Each product has been developed to meet specific acoustic requirements. From apartments to industrial facilities, available materials allow customization according to individual needs.

Properties and structure of absorbing materials

Sound-absorbing foams are characterized by a unique internal structure. Numerous interconnected micropores create a complex labyrinth where sound waves lose energy. Material thickness influences absorption efficiency, especially for low frequencies. Profile shapes such as pyramids or waves increase the absorbing surface area.

Technical parameters of available materials: Thickness from 10 to 50 millimeters, self-adhesive and non-adhesive variants, various colors and panel shapes, absorption coefficient reaching 0.9 at selected frequencies.

The durability of the foams is guaranteed by high resistance to mechanical damage. The porous structure does not promote moisture accumulation or mold growth. Proper maintenance ensures long-term retention of acoustic properties. The material remains flexible and does not become brittle even after years of use.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

Applications and Installation in Various Spaces

Acoustic foams are used both in residential and commercial spaces. Recording studios, conference rooms, and offices use these materials daily. Installation in children’s rooms provides a quiet environment for learning and rest. Soundproofing residential buildings reduces noise from the street and neighbors.

Popular installation areas for materials: Exterior walls facing noise sources, room corners for low-frequency control, ceiling surfaces above noise-prone areas, doors and windows for additional insulation.

Installing self-adhesive variants does not require specialized tools or skills. Preparing a clean and dry surface is enough for quick installation. Panels without a self-adhesive layer can be attached using adhesives designed for polyurethane materials. Flexible mounting allows later removal without damaging the substrate.

Operations and Experience of ABM Insulation

ABM Insulation has been operating in the insulation industry since 2010, building a solid reputation as a supplier of high-quality materials. Many years of experience have enabled the development of products that meet the highest industry standards. A modern production facility guarantees consistent quality for every batch of materials.

Expanding operations to European markets in 2012 confirms the company’s professionalism. Current partnerships with international clients demonstrate trust in ABM Insulation’s products. A strategic location near Warsaw facilitates fast order fulfillment throughout Poland.

Contacting the ABM Insulation team provides professional advice on selecting the appropriate thickness and type of foam for specific acoustic requirements of a room.

The sound-absorbing foams available at ABM Insulation’s store offer a comprehensive solution to noise problems. Each product has been selected with performance, safety, and durability in mind. By working with ABM Insulation, you gain access to materials trusted and verified by professionals.

Interested customers can review the full range of available products in the online store. The professional team at ABM Insulation is available to provide guidance on choosing the right materials. Fast delivery and solid technical support guarantee satisfaction with every purchase.

Comparison of Effectiveness of Various Soundproofing Solutions for Nighttime Rooms

The acoustic materials market requires an informed choice. Different products have varying properties and effectiveness. Polyurethane foams are one of many available solutions. Comparing alternatives helps make an accurate purchasing decision.

Parents look for safe, effective, and aesthetically pleasing materials. The product price also plays an important role in the selection process. Ease of installation and the possibility of self-installation reduce overall costs. Material durability determines the cost-effectiveness of a long-term investment.

Polyurethane Foam Compared to Other Sound-Absorbing Materials

Polyurethane foam features an excellent effectiveness-to-price ratio. The sound absorption coefficient reaches values of 0.9-0.95 for selected frequencies. The material effectively reduces noise by 7.5-10 dB. Its open-cell structure provides high acoustic energy absorption.

Rubber foam is an alternative to polyurethane solutions. The material exhibits higher density and better impact sound insulation. The elasticity of rubber ensures excellent vibration damping. Its use in floor insulation yields outstanding results. The price of rubber foam exceeds the cost of polyurethane.

Butyl mats are designed for vibration damping. This material effectively reduces sounds transmitted through the building structure. The high specific mass of the mat blocks the propagation of acoustic waves. Combining butyl mats with polyurethane foam delivers the best results. Installation requires a stronger fastening system.

| Material | Absorption Coefficient | Noise Reduction | Price per m² | Ease of Installation |

|---|---|---|---|---|

| Polyurethane Foam | 0.9-0.95 | 30-40 dB | 5-15 EUR | Very Easy |

| Rubber Foam | 0.7-0.85 | 25-35 dB | 10-20 EUR | Easy |

| Butyl Mat | 0.6-0.75 | 20-30 dB | 15-30 EUR | Medium |

| Mineral Wool | 0.8-0.9 | 25-35 dB | 3.75-10 EUR | Difficult |

| Wooden Panels | 0.5-0.7 | 15-25 dB | 20-50 EUR | Medium |

Mineral wool exhibits good sound absorption properties. The lower price attracts customers seeking economical solutions. Installation requires creating a supporting structure and cladding. Mineral fibers can irritate the respiratory tract. Use in children’s rooms requires a sealed cover.

Perforated wooden panels combine acoustic function with aesthetics. Holes in the wood allow sound absorption through the inner layer. High material and installation costs limit the popularity of this solution. The visual effect adds elegance to interiors with a modern character.

Actual results of noise reduction in home conditions

Research on the effectiveness of acoustic panels confirms their efficiency. An experiment with infant rooms showed noise reduction below 50 dB. Before panel installation, the level exceeded safe standards. The use of acoustic foams lowered the intensity to recommended values.

Apartments near busy streets experience noise levels of 65-75 dB. Installing 5 cm thick polyurethane foams on the exterior wall reduces the level by 30-35 dB. The resulting noise level of 35-45 dB falls within the standard for bedrooms. Sleep quality improves significantly.

Rooms adjacent to noisy spaces require thinner foam layers. A 3 cm layer effectively dampens sounds of conversations and television. Reduction by 20-25 dB lowers the level from 60 dB to 35-40 dB. A child can sleep peacefully despite household activity.

Footstep noise from the apartment above is a problem in multi-family buildings. Acoustic foams installed on the ceiling reduce impact sounds by 15-20 dB. Combining with a butyl mat increases effectiveness by another 10-15 dB. Total reduction of 25-35 dB significantly improves acoustic comfort.

Reverberation inside a room shortens after applying foams. Reverberation time in an untreated room is 0.8-1.2 seconds. Installing foams on 30% of the surface reduces reverberation to 0.3-0.5 seconds. Speech sound clarity increases, and echo disappears.

Cost-benefit ratio for acoustic and health benefits

Prices for polyurethane acoustic foams range from €3.50 to €45 per panel. Pyramid foams measuring 50×50 cm and 5 cm thick cost about €3.50-4.50. Larger sheets measuring 100×200 cm at the same thickness cost €28.50-35.25. Self-adhesive versions are 20-30% more expensive.

ABM FALA wavy foams are available at prices from €5.75 to €23.25. The 20 mm thickness in smaller formats costs about €5.75-8.50. The 40 mm layer in larger sheets reaches prices of €21.75-23.25. Self-adhesive versions facilitate installation without additional glue costs.

The cost of acoustic adaptation for a children’s room of 12 m² is €75-200. Covering 30% of wall and ceiling surfaces requires about 10-15 m² of foam panels. Choosing standard pyramid foams reduces costs to the lower range limit. Premium foams with self-adhesive layers increase expenses.

Health benefits justify the investment:

-

Improvement of the child’s sleep quality and body regeneration

-

Reduction of acoustic stress and improvement of well-being

-

Support for cognitive and language development

-

Reduction of the risk of hearing disorders and behavioral problems

-

Better concentration during learning and play

The durability of polyurethane foams exceeds 10-15 years with proper use. The annual cost of acoustic adaptation ranges from 5-15 EUR. The value of a child’s health and comfort far outweighs these expenses. The investment pays off by improving the quality of life for the entire family.

Self-installation eliminates specialist service costs. Professional installation would cost an additional 125-375 EUR. The simplicity of installing self-adhesive foams allows saving this amount. Parents can allocate funds to purchase higher-quality materials.

Comparison with other soundproofing solutions shows the cost-effectiveness of polyurethane foams. Mineral wool requires a supporting structure costing 50-100 EUR. Perforated wooden panels exceed the budget at 500-1,250 EUR. Polyurethane foams combine effectiveness with an affordable price.

Tip: Starting acoustic adaptation by installing foam in the loudest areas of the room allows assessing the effect and possibly expanding the installation, minimizing initial expenses while maintaining the possibility of future project development.

FAQ: Frequently Asked Questions

Are polyurethane acoustic foams safe for a child’s health, and can they cause allergies?

Polyurethane acoustic foams, once fully cured, do not pose a health risk to children. The material is biologically neutral and does not promote the growth of mold, fungi, or dust mites. When purchasing foams, it is important to require certificates such as the PZH Hygiene Certificate or Greenguard certification, which confirm product safety.

Those choosing foams should know that volatile organic compound emissions mainly occur during transport and storage. After unpacking the material in a well-ventilated room, odors dissipate quickly. Child-safe foams do not emit toxins nor contain formaldehyde at levels exceeding standards. Proper storage before installation ensures even greater safety for young children’s health.

How many decibels does polyurethane foam reduce, and is it effective enough for a child’s room?

The effectiveness of polyurethane foam in noise reduction reaches 30–40 decibels depending on material thickness and applied solution. Foams with a thickness of 5 centimeters can lower sound levels from 65–70 dB to about 35–40 dB. Experts recommend using the material as follows: Foam efficiency parameters: thickness of 2–3 centimeters reduces high frequencies, a 5-centimeter layer controls mid-tones, and 10 centimeters dampen low frequencies.

Safety standards for children’s bedrooms require noise levels below 50 decibels. Proper thickness selection and installation in strategic locations cover all necessary decibel reductions. Combining different thicknesses on external and internal walls provides comprehensive acoustic protection.

How to properly install self-adhesive acoustic foam in a child’s room without damaging the walls?

Installing self-adhesive foam requires a few simple steps to achieve a durable and secure bond. Surface preparation is a key stage of the installation. The wall must be clean, dry, and free of grease, dirt, or dust. Using a mild detergent and a microfiber cloth removes deposits and prepares the surface for installation. After drying the surface, wait a few minutes before applying the foam.

The installation involves carefully peeling off the protective film from the adhesive layer and pressing the panel onto the wall. Applying steady pressure over the entire foam surface for 5–10 seconds ensures full adhesion of the glue. The material does not leave permanent marks after removal, and minor residues can be easily wiped off with a sponge. This solution works perfectly in rented apartments and does not require any alteration to the building structure.

Does installing foam in a child’s room affect air volume or cause overheating of the rooms?

Polyurethane acoustic foams do not significantly reduce room volume. The thickness of a standard panel is only 5 centimeters, which even when covering walls fully reduces the room’s volume by a margin. The material has an open structure that allows natural air circulation. Temperature properties of the foam: its cellular structure supports regular airflow; the material does not emit heat nor affect room temperature; the foam surface maintains ambient temperature.

Natural ventilation in the child’s room remains unchanged after installing the foam. The porous structure of the material does not act as an air barrier to the same extent as traditional building insulation. Concerns about heat or sweat accumulation in the room are unfounded. Regularly airing out the room through open windows provides optimal health conditions for the child.

What are the actual prices of acoustic foam in Poland, and is soundproofing an entire child’s room financially accessible for an average family?

The prices of acoustic foam in Poland vary significantly depending on product parameters. Pyramid foams measuring 50 by 50 centimeters cost from €3.25 to €5.75 per piece. Larger panels measuring 100 by 100 centimeters with standard density of 140 kilograms per cubic meter cost about €15. Self-adhesive foams are 20 to 30 percent more expensive, with prices reaching around €20 per standard panel. Estimated adaptation costs for a room: fully soundproofing a 12–15 square meter room requires an investment of €75–€200; DIY installation eliminates specialist service costs; annual maintenance costs amount to only €5–€15.

An average family can opt for gradual soundproofing, starting with walls most exposed to noise. This approach spreads expenses over many months and makes the investment financially accessible. Besides pyramid foams, cheaper options such as smooth or wavy panels are also available, with prices starting at several euros per piece.

Summary

Polyurethane acoustic foams provide an effective solution to noise problems in children’s rooms. The open-cell structure of the material absorbs sound waves and converts acoustic energy into heat. Noise reduction of 30-40 dB creates a calm environment conducive to recovery. An absorption coefficient reaching values of 0.9-0.95 demonstrates the high efficiency of the foams.

The safety of polyurethane materials confirmed by certificates is a key advantage. PZH Hygiene Certificates and RoHS certifications guarantee the absence of harmful substances. Anti-allergic and non-toxic properties protect the health of the youngest. The durability and flexibility of the material ensure long-lasting acoustic properties. The soft surface of the foams protects against mechanical injuries during play.

Children’s sleep quality significantly improves in an acoustically controlled environment. Scientific studies document the negative impact of noise exceeding 55 dB on sleep microstructure. Reducing nighttime awakenings by over 50% allows for full body regeneration. Cognitive development and concentration increase in a quieter environment. Improving room acoustics supports the child’s physical and mental health.

Installing polyurethane foams does not require specialized skills or tools. Strategic placement of panels relative to noise sources maximizes effectiveness. Self-adhesive layers allow installation without damaging walls. The cost of adapting an acoustic room ranges from 75 to 200 EUR. Health benefits and improved family quality of life far outweigh this investment. Polyurethane foams combine effectiveness, safety, and affordability in a comprehensive acoustic solution.