Sound absorption fundamentally differs from acoustic insulation, although these concepts are often confused. Acoustic foams, despite common belief, do not serve as a barrier against external noise. Their main task is to control internal acoustics by reducing echo and reverberation in the space.

The structure of acoustic foams is based on air-filled pores that absorb sound waves. Acoustic energy is converted into heat during the friction of air particles against the walls of microscopic channels. This process effectively improves acoustic comfort in conference rooms or recording studios.

Choosing the right acoustic solution requires understanding the physical properties of materials. Density, thickness, and NRC rating determine the actual effectiveness of absorption. ABM Insulation provides a comprehensive response to various acoustic needs of spaces.

The fundamental difference between soundproofing and improving room acoustics

Acoustic insulation and improving acoustics represent two distinct approaches to sound control. Insulation blocks noise transmission between rooms, while absorption reduces reflections within the space. Acoustic foams focus solely on the latter aspect, enhancing sound quality.

Sound-absorbing materials work by reducing reflections from walls and ceilings. Covering surfaces with foam eliminates unwanted echo that distorts sound perception. A recording studio requires such acoustic control, without which obtaining a clean recording is impossible.

How sound absorption works in acoustic foams

Sound waves penetrate the porous structure of the foam instead of reflecting off surfaces. Inside the material, air particles vibrate in microscopic channels, causing friction. The kinetic energy of the wave gradually converts into thermal energy, dissipating within the material.

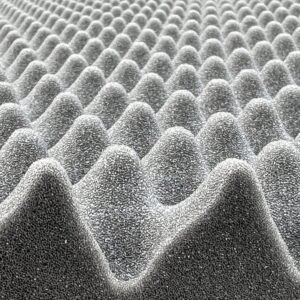

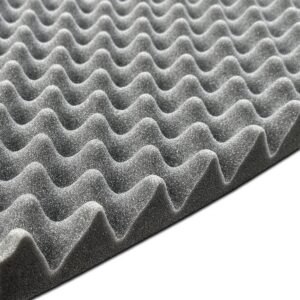

The size of the pores determines the frequency range subject to absorption. Larger pores absorb lower tones, while finer structures effectively dampen high sounds. The shape of the foam surface increases the total absorbing area through multiple reflections between profiled elements.

The absorption mechanism in foams:

- Pentration of sound waves into the porous structure of the material

- Vibrations of air particles trapped between pores

- Friction against the walls of microscopic channels inside the foam

- The conversion of acoustic energy into heat occurs as a result of dissipation processes

- Dissipation of remaining energy within the structure

- Minimization of reflections returning to the room

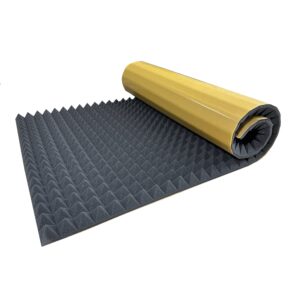

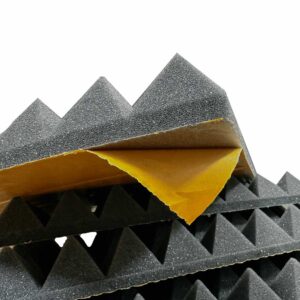

Pyramidal foams achieve absorption effectiveness close to 100 percent at frequencies from 1000 to 4000 Hz. The angle of inclination of pyramids significantly affects damping properties. Structures with a 35-degree angle outperform those with a 20-degree angle.

What is the actual acoustic insulation of walls and ceilings

Acoustic insulation requires materials with high surface mass that block sound transmission. The principle is based on physics stating that heavier barriers are harder to set into vibration. ABM Professional Butyl Mat increases the mass of the wall, reducing noise transmission.

Effective insulation uses high-density materials installed directly on the structure of the partitions. Insulating Rubber Foam ABM Insulation, available in thicknesses from 3 to 19 mm, provides thermal and acoustic barriers. The closed-cell structure minimizes sound conduction.

Properties of insulating materials:

- Density above 100 kilograms per cubic meter

- Closed-cell structure preventing air flow

- Surface mass exceeding 5 kilograms per square meter

- Moisture resistance eliminating the risk of degradation

- Flexibility allowing for tight adherence to surfaces

ABM Xtreme Butyl Mats contain a layer of aluminum foil that additionally reflects sound waves. Thickness from 1.3 to 4 mm ensures effective vibration damping in automotive and construction applications. The material does not contain asphalt, eliminating the risk of cracking.

Why foams do not block noise from adjacent rooms

Acoustic foams have an open-cell structure that allows sound to pass through. The low mass of the material does not provide a barrier for waves traveling through the air. Acoustic energy penetrates through the foam, continuing to propagate into the adjacent room.

The permeability of sound results from micro-leaks present in the porous structure. Every acoustic wave always reaches the other side of the material to some extent. The partition allows sound to pass through via its own vibrations and numerous spaces between pores.

The acoustic impedance of foam differs significantly from that of air, causing reflections from surfaces. The absorption coefficient reaches a value of 1 only with perfect impedance matching. Standard foams absorb part of the energy, but the remainder transmits through the material without significant weakening.

The thickness of foam required for effective insulation would need to be at least one-quarter of the wavelength. For a frequency of 100 Hz, the wavelength is 3.4 meters, so an effective insulator would need a thickness of about 48 centimeters.

Physical properties of foam determining its effectiveness

The material parameters directly influence the ability to absorb acoustic waves. The density of the structure determines the range of frequencies subject to absorption. The thickness of the layer determines the minimum frequency effectively dampened by the material.

The shape of the foam surface increases efficiency by dispersing waves at various angles. Pyramidal structures create multiple reflections within the profiles, maximizing energy absorption. ABM Insulation materials combine optimal physical parameters with practical installation.

The Importance of Material Density for Sound Wave Damping

The acoustic density of the material affects the resistance encountered by moving air particles. Higher density increases friction within the structure, intensifying the conversion of energy into heat. Foams with a density of 35 euros per cubic meter absorb significantly more energy than standard materials.

Too low a density does not provide sufficient resistance to sound waves. Conversely, excessive density closes pores, hindering sound penetration into the structure. The optimal density for acoustic foams ranges from 5 to 15 euros per cubic meter.

| Material Density | Absorption Efficiency | Frequency Range | Application |

|---|---|---|---|

| 20-30 kg/m³ | Average | 500-5000 Hz | Home studios, conference rooms |

| 60-80 kg/m³ | High | 250-8000 Hz | Professional recording studios |

| 100-140 kg/m³ | Very High | 125-10000 Hz | Cinemas, concert halls |

Rubber insulation foam ABM Insulation is characterized by high density, providing an effective acoustic barrier. Its closed-cell structure increases the mass of the partition, reducing airborne noise transmission. The material is effective in automotive and construction applications.

High-density foams excel at absorbing airborne sounds, such as conversations or music. They increase the mass of the building partition, helping to limit the amount of noise penetrating through the wall. They are effective as insulation against airborne and impact sounds of medium and high frequencies.

Foam Thickness and Absorption of Different Frequencies

The minimum thickness of an effective absorber is one-quarter of the wavelength being absorbed. In practice, the material absorbs sound starting from one-seventh of the wavelength. A foam thickness of 5 centimeters effectively dampens frequencies above 970 Hz.

Low frequencies require significantly thicker materials due to their wavelength. A tone with a frequency of 100 Hz has a wavelength of 3.4 meters. Effective absorption of such sound requires foam with a minimum thickness of 48 centimeters.

The Relationship Between Thickness and Absorbed Frequencies:

- Foams 2-3 cm thick effectively dampen only high frequencies above 2000 Hz

- A layer 4-5 cm thick absorbs frequencies from 1000 Hz upwards

- A thickness of 10 cm allows for absorption from 250 Hz

- Material over 20 cm controls low tones below 125 Hz

Pyramidal foams with high pyramids above 5 centimeters demonstrate good effectiveness in the low-frequency range. The increased height of the profile extends the wave path within the structure, intensifying energy dissipation. The shape of the pyramids further increases the effective thickness of the material.

The acoustic foam from ABM Insulation is available in various thicknesses tailored to specific needs. A layer of 4 centimeters works well in recording studios, while 10 centimeters provides control over a wide spectrum of frequencies.

Tip: Installing foams at a distance from the wall increases effective absorbing thickness, improving low-frequency absorption without increasing the thickness of the material itself.

NRC Coefficient as a Measure of Actual Sound Absorption Efficiency

The Noise Reduction Coefficient is a key metric that determines the effectiveness of sound-absorbing materials. NRC values range from 0 to 1, expressing the percentage absorption of acoustic energy. Standardized tests at frequencies of 250, 500, 1000, and 2000 Hz provide comparable results.

The NRC measurement allows for an objective assessment of various acoustic materials. Polyurethane foams and mineral wool exhibit different absorption profiles depending on frequency. The practical application of this coefficient facilitates selecting solutions for specific spaces.

How to Interpret NRC Values from 0 to 1 for Different Materials

An NRC value of 0 indicates total reflection of sound with no energy absorption. A value of 1 indicates absorption of 100 percent of the incident acoustic wave. A material with an NRC of 0.85 absorbs 85 percent of energy, effectively reducing noise levels.

Standard acoustic foams achieve NRC values from 0.5 to 0.9 depending on thickness. A 10-millimeter foam achieves a rating of 0.15 to 0.30, absorbing only 15-30 percent of sound. Thicker materials provide proportionally higher effectiveness.

Interpreting the coefficient requires consideration of the application context. An NRC value of 0.6 may be sufficient in an office where reducing reverberation improves comfort. However, a recording studio requires materials with an NRC above 0.8 for precise acoustic control.

Standard acoustic tests at frequencies from 250 to 2000 Hz

NRC tests measure absorption at four standard frequencies representing the human speech range. Measurements at 250 Hz assess the absorption of low tones in male voices. Frequencies of 500 and 1000 Hz correspond to the average vocal range.

A study at 2000 Hz verifies the material’s effectiveness against high components of speech and music. The averaged value from the four measurements constitutes the final NRC coefficient. The procedure ensures consistent comparison of different materials under laboratory conditions.

Methodology for standard acoustic tests:

- Placement of the material sample in a reverberation chamber with controlled parameters

- Emission of a test signal at a specified frequency and intensity

- Measurement of reverberation time before installing the material

- Measurement of reverberation time after installing the sample

- Calculation of the absorption coefficient based on the difference in measurements

- Averaging results for four test frequencies

ISO 354 standards regulate procedures for measuring sound absorption coefficients. The reverberation chamber must meet strict requirements regarding size and acoustics. The material sample occupies an area from 10 to 12 square meters for reliable results.

Comparison of the effectiveness of polyurethane foams and mineral wool

Polyurethane foams demonstrate higher effectiveness in the medium and high frequency ranges. Their profiled surface increases absorption by scattering waves at various angles. Mineral wool surpasses foams in absorbing low tones due to its greater density.

The NRC coefficient of polyurethane foams with a thickness of 5 centimeters ranges from 0.6 to 0.8. Mineral wool of the same thickness achieves values from 0.7 to 0.9, particularly effective at lower frequencies. The choice of material depends on the dominant noise sources.

| Material | NRC Coefficient | Effectiveness 250 Hz | Effectiveness 1000 Hz | Effectiveness 2000 Hz |

|---|---|---|---|---|

| 5 cm Polyurethane Foam | 0.65-0.75 | Average | High | Very High |

| 5 cm Mineral Wool | 0.75-0.85 | High | Very High | High |

| 3 cm Rubber Foam | 0.50-0.65 | Low | Average | High |

Mineral wool absorbs speech sounds more effectively due to its absorption in the range of the fundamental frequency of the human voice. Polyurethane foams better control mechanical sounds with higher harmonics. Environments with loud music utilize pyramid profiles.

Acoustic foam absorbing ABM Insulation combines the advantages of polyurethane structure with optimal density. The material effectively reduces echo and reverberation in rooms with specific acoustic requirements. Its use in studios and conference rooms confirms high efficiency.

Practical application of the coefficient when choosing solutions

The NRC value serves as a starting point for calculating the required surface area of absorbing material. A room with strong reverberation requires coverage of 30-40 percent of the wall and ceiling surfaces. A space with a long reverberation time needs materials with a higher coefficient.

The calculation is based on the volume of the room and the desired reverberation time. Sabine’s formula combines the absorption coefficient with the surface area of the material, determining the final acoustics. A recording studio requires a reverberation time of 0.3-0.4 seconds, while a conference room tolerates 0.6-0.8 seconds.

Tip: Combining materials with different absorption profiles provides uniform control across the entire frequency spectrum, eliminating acoustic issues more effectively than a single type of foam.

When acoustic foams truly improve comfort in a room

Controlling sound reflections in work and recreational spaces directly affects user comfort. Reducing echo eliminates auditory fatigue during long conversations or music listening sessions. Recording studios and conference rooms require precise acoustic control for optimal functionality.

Acoustic foams absorb unwanted reflections, improving speech intelligibility and recording clarity. Strategic placement of materials at first reflection points maximizes effectiveness. Office and educational spaces benefit from reduced background noise levels.

Reduction of echo and reverberation in recording studios and conference rooms

Controlling early reflections is a priority in recording studios, where microphones capture every acoustic imperfection. Foams installed at first reflection points eliminate interference between direct and reflected sound. A clean signal allows for precise processing during post-production.

Conference rooms require a short reverberation time to ensure speech intelligibility. Excessive reflections cause syllable overlap, making it difficult to perceive messages. Acoustic foams shorten reverberation time to an optimal range of 0.6-0.8 seconds.

Strategic mounting points for acoustic foams:

- Side walls parallel to the speakers or speaker

- Ceiling above the listening or conference position

- Back wall behind the operator’s station or audience

- Room corners as bass traps

- Space behind monitors or projection screens

Vocal booths use foams to create a controlled acoustic environment. Surrounding the vocalist with absorbing material isolates the voice from background sounds. Strategically leaving rear reflections adds natural depth to the sound.

The acoustic absorbing foam from ABM Insulation eliminates echo and shortens reverberation time in professional spaces. The main advantage of using it is the significant reduction of noise levels and improvement in sound quality. Absorbing unwanted waves contributes to the elimination of acoustic problems.

Limitations of foam materials at low frequencies

Standard acoustic foams do not effectively control frequencies below 250 Hz. The wavelength of low tones significantly exceeds the thickness of typical materials. Sound waves penetrate through the foam without significant energy absorption.

Effective bass control requires special solutions, such as bass traps installed in corners. Room corners are areas where low-frequency energy concentrates. Thick panels or a combination of different materials provide better results.

The rubber insulation foam from ABM Insulation with a thickness of 13-19 mm absorbs low frequencies more effectively. Its closed-cell structure and high density increase the mass of the barrier. The material is effective in automotive applications for dampening rumble and vibrations.

Tip: Installing foams at distances of 10-15 centimeters from the wall creates an air space that significantly increases low-frequency absorption without the need for thicker materials.

Acoustic polyurethane foams and panels at ABM Insulation store

ABM Insulation Online Store specializes in providing professional acoustic solutions for various applications. The range includes absorbing acoustic foams with an open-cell structure, effectively reducing echo and reverberation in rooms. The products feature high material density, ensuring optimal sound wave absorption.

The company, operating since 2010, supplies insulation materials to the Polish market and countries within the European Union. The rich offer includes foams available in various thicknesses and surface profiles, such as pyramids and waves. All products have appropriate certifications confirming their effectiveness in controlling room acoustics.

Professional polyurethane foams for acoustic control

Absorbing acoustic foams available at ABM Insulation store are made from high-quality materials. The open-cell structure ensures effective absorption of unwanted sound reflections. The materials are offered in self-adhesive versions as well as those requiring the use of mounting glue.

The thickness of the products ranges from 10 to 50 millimeters, allowing for selection based on specific requirements. Pyramid profiles increase the total absorption surface by dispersing waves at various angles. White polyurethane foams are suitable for spaces requiring aesthetic finishing.

Basic variants of available foams:

- Pyramid profiles with a height of 50 millimeters effective in recording studios

- Wavy surfaces with a thickness of 15 to 40 millimeters universal for conference rooms

- Flat panels from 10 to 30 millimeters ideal for offices and residential spaces

- Self-adhesive materials enabling quick installation without additional tools

Flame-retardant products enhance safety in various environments. Resistance to moisture and mechanical factors ensures long-lasting acoustic properties.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

Wide application of sound-absorbing materials

Sound-absorbing materials from ABM Insulation find use in numerous industries and spaces. Recording studios utilize foams to precisely control acoustics during sound recording. Conference rooms benefit from improved speech intelligibility by reducing reverberation time.

Residential and office spaces take advantage of background noise reduction, enhancing everyday comfort. The automotive, industrial, and construction sectors use materials for soundproofing machines and technical rooms. Fast order fulfillment within 24 hours ensures efficient delivery throughout Poland.

Comprehensive support and technical advice

The team of professionals at ABM Insulation provides reliable advice on selecting appropriate acoustic solutions. An individual approach to each project guarantees optimal results tailored to specific requirements. Years of experience since 2010 translate into high-quality customer service.

Collaboration with companies from Germany, the United Kingdom, Sweden, and the Netherlands confirms international recognition of the products. Well-organized logistics enable quick delivery of insulation materials even beyond Poland’s borders. Professional technical support facilitates the execution of even the most demanding acoustic projects.

We invite you to purchase absorbing acoustic foams at the ABM Insulation online store. Contact our team for expert consultation and selection of optimal materials for your project. We guarantee the highest quality products and fast order fulfillment.

Selection of Appropriate Solutions for Specific Acoustic Problems

The analysis of the nature of the acoustic problem determines the choice of materials and technologies. Improving indoor acoustics requires absorbing materials with an appropriate NRC rating. Blocking external noise needs insulation solutions with high surface mass.

A combination of different technologies provides comprehensive acoustic protection in demanding environments. ABM Insulation materials include both absorbing foams and insulation mats. Professional consulting facilitates the selection of an optimal product set for a specific space.

When Improvement of Acoustics is Sufficient Without Full Isolation

Rooms without issues from penetrating external noise only need control of internal acoustics. Open space offices suffer from excessive reverberation generated by conversations and equipment. Acoustic foams mounted on ceilings and selected walls shorten the reverberation time.

Home theaters require a reduction in reflections to improve sound immersion. The flanking effect of reflecting waves disrupts the spatiality of the surround system. Strategic placement of foams at first reflection points eliminates the problem without interfering with wall construction.

Spaces Requiring Only Acoustic Improvement:

- Offices and coworking spaces with echo problems

- Conference and lecture rooms to improve speech intelligibility

- Home studios for recording podcasts and video materials

- Home theaters for better sound spatiality

- Gaming rooms eliminating echo from speakers

Restaurants and cafes benefit from reducing background noise levels. The acoustics of these spaces directly affect guest comfort. Acoustic panels mounted on ceilings absorb reflections, lowering the overall sound level in the establishment.

ABM Insulation Absorbing Acoustic Foam is used in home theaters and conference rooms. The material absorbs unwanted sound waves, contributing to the elimination of echo and shortening reverberation time. The specificity of acoustic requirements for the space is crucial.

Situations Requiring High-Density Materials

Rooms exposed to intense external noise need materials that block sound transmission. Apartments near busy streets require increased mass in partitions. ABM Professional Butyl Mat mounted on walls reduces the penetration of traffic noise.

Professional recording studios combine absorption with insulation to eliminate external disturbances. Butyl mats cover structural walls before mounting absorbing foams. A two-layer solution blocks noise and controls internal acoustics.

Applications of High-Density Materials:

- Apartments in buildings with poor sound insulation

- Recording studios requiring complete isolation from the surroundings

- Rehearsal rooms generating intense noise

- Rooms near expressways and railway lines

- Industrial spaces with loud machinery

ABM Xtreme Butyl Mats feature a density that provides effective noise and rumble reduction. The layer of aluminum foil reflects additional sound waves. The material does not contain asphalt, eliminating the risk of cracking in extreme temperatures.

High-Density Rubber Insulation Foam ABM Insulation absorbs airborne sounds, such as conversations and music. It increases the mass of the building partition, helping to limit noise penetrating through the wall. Effective insulation against airborne and impact sounds of medium and high frequencies.

Combining Different Technologies for Optimal Results

A comprehensive acoustic solution requires a combination of insulating and absorbing materials. The first layer increases the mass of the partition, blocking noise transmission. The second layer controls internal acoustics, eliminating reflections and reverberation.

ABM Butyl Mat installed directly on the structural wall serves as an insulating base. Acoustic foam installed on the damping layer controls reflections inside the room. The system provides both silence and optimal acoustics.

The corners of rooms require special bass traps for low-frequency control. A combination of thick foams and high-density materials dampens modal resonances. Remaining surfaces are covered with standard foams that absorb mid and high tones.

Tip: First, install the insulation layer on the structural walls, then mount the absorbing foams to create a complete room acoustic control system.

FAQ: Frequently Asked Questions

How much acoustic foam is needed to soundproof a room?

Effective acoustic correction requires covering about 30 to 40 percent of wall surface area with absorbing foams. A smaller amount of material may not yield expected results, especially in large spaces. The size of the room determines the number of acoustic panels needed. Conference rooms typically require more coverage area than small home studios.

The strategic placement of material is more important than completely covering all walls. First reflection points, the ceiling above the workstation, and the back wall are priority installation locations. Room corners concentrate low-frequency energy, so they require special bass traps.

Can acoustic foams be painted, and how does it affect their properties?

Paining acoustic foams significantly reduces their sound absorption capability. Paint fills pores in the material structure, preventing acoustic wave penetration. The open cell structure is a key element in foam performance. Closing pores transforms the absorbing material into a sound-reflecting surface.

Solvent-based paints can additionally damage the structure of polyurethane foam. Some chemicals dissolve the material, causing deformation. Water-based paints are less aggressive; however, they also limit absorption effectiveness. Decorative panels available in various colors eliminate the need for painting while maintaining full acoustic functionality.

What thickness of acoustic foam is optimal for different applications?

A thickness of 2 to 3 centimeters works well in home theaters and offices, where the main issue is high frequencies above 2000 Hz. A layer of 4 to 5 centimeters absorbs frequencies from 500 Hz upwards, ensuring control over human voice and most musical instruments. Professional recording studios require foams with a minimum thickness of 10 centimeters for a wide range of absorption.

Low frequencies below 250 Hz need significantly thicker materials due to the wavelength. Pyramid profiles taller than 5 centimeters increase effective thickness by extending the wave path within the structure. Mounting foams at a distance from the wall further improves bass absorption without increasing the thickness of the material itself.

How to properly install acoustic foams on the wall?

Acoustic mounting adhesive is the most popular installation method, providing a durable and strong bond with the surface. The wall must be clean, dry, and even before starting installation. Applying adhesive in several spots on the back of the foam is sufficient for sheets up to 50 by 50 centimeters. Larger panels require an even spread of adhesive across the entire surface.

Double-sided tape offers an alternative that allows for removal without damaging walls. This method works well in rented apartments where permanent mounting is not desired. Special mounting frames allow for quick panel replacement and flexible arrangements. The material should be pressed against the wall evenly for several seconds to ensure full adhesion.

Are acoustic foams suitable for soundproofing an apartment from neighbor noise?

Acoustic foams do not block external noise coming from neighboring apartments. Their task is solely to improve internal acoustics by reducing echo and reverberation. The low mass of the material does not provide a barrier for sound waves traveling through building partitions. The open-cell structure allows sound to pass through instead of stopping it.

Effective sound insulation from neighbor noise requires high-density materials mounted directly on structural walls. ABM Professional butyl mat increases partition mass, reducing sound transmission. ABM Insulation rubber insulation foam with a density above 100 kilograms per cubic meter provides a real acoustic barrier. A multi-layer system combining insulation with absorption guarantees comprehensive protection against external noise and control over internal acoustics.

How do acoustic foams differ from regular upholstery foams?

Acoustic foams have a special physical structure that increases sound absorption. A greater number of cells per square inch translates to better absorption of acoustic energy. The PPI value, which defines the number of pores, determines the range of frequencies absorbed. Upholstery foams have a closed cell structure designed for mechanical cushioning, not sound absorption.

The density of acoustic foams ranges from 20 to 140 kilograms per cubic meter, while upholstery materials achieve different parameters. The profiled surface of pyramids or waves increases the total absorbing surface area. Regular foams have a smooth surface that reflects most acoustic energy. Upholstery materials have not undergone NRC coefficient testing, so their acoustic effectiveness remains unknown.

Summary

Acoustic foams effectively improve the acoustic comfort of rooms by reducing echo and reverberation but do not act as a barrier against external noise. Their operation is based on absorbing sound waves within a porous structure, where energy is converted into heat. Acoustic insulation requires high-density materials that block sound transmission between spaces.

The NRC coefficient is a key metric determining the effectiveness of sound-absorbing materials. Values range from 0 to 1 and express the percentage of acoustic energy absorption at standard frequencies. Choosing the right solution requires analyzing the nature of the acoustic problem and the dominant frequency ranges in the room.

ABM Insulation materials include both absorbing foams for controlling internal acoustics and insulation mats for blocking external noise. The combination of different technologies provides comprehensive acoustic protection in demanding environments. Professional recording studios and industrial spaces utilize multilayer systems that combine insulation with absorption for optimal results.

Sources:

- https://en.wikipedia.org/wiki/Sound_absorption_coefficient

- https://pl.wikipedia.org/wiki/Poch%C5%82anianie_d%C5%BAwi%C4%99ku

- https://www.acousticalsurfaces.com/blog/acoustics-education/acoustic-panels-vs-foam/

- https://cellyx.com/2025/02/05/the-science-of-soundproofing-acoustic-foam-and-nrc-ratings-explained/

- https://us.tchweb.com/blogs/foam-fabrication/5-key-differences-between-acoustic-foam-and-soundproofing-foam-common-misconception