Car soundproofing is an investment that brings tangible benefits to enthusiasts of good music sound. Eliminating road noise and body vibrations allows for the full utilization of the audio system’s capabilities inside the cabin. The music sounds exactly as the equipment manufacturers intended, without unwanted distortions and interference.

Many drivers wonder if soundproofing really affects listening quality. The answer is a definite yes. A cabin free from external noise transforms into a space where every element of the recording becomes clearer. The bass gains precision, midrange sounds natural, and high tones don’t get lost in the noise of rolling tires.

How car soundproofing works on a physical level

The physical principles of soundproofing are based on transforming sound energy into heat. Insulating materials absorb acoustic waves before they can penetrate the cabin interior. At the same time, they dampen structural vibrations that occur during driving.

The structure of modern soundproofing materials resembles a layered defense system. Each layer addresses a different type of acoustic disturbance. Butyl mats eliminate mechanical sheet metal vibrations, while foams absorb sound waves penetrating through metal.

Principle of damping vibrations in metal body parts

The body sheet metal acts like a speaker diaphragm, transmitting vibrations across its entire surface. Without proper damping, the whole body becomes a resonator for unwanted sounds. Butyl materials change the mechanical properties of metal by adding mass and stiffness.

The damping layer converts the kinetic energy of vibrations into thermal energy within its structure. This process occurs in the polymer matrix of the material, which deforms under vibration influence. A thicker butyl mat more effectively dampens low frequencies, which easily propagate through metal structures.

Mechanism of butyl mats operation:

- Adding mass to the metal surface increases structural inertia

- Flexible butyl absorbs mechanical vibration energy

- Kinetic energy converts into heat inside the material

- Aluminum foil increases overall layer stiffness

- Reduces vibration amplitude by seventy percent with proper installation

ABM Professional Mats contain high-density butyl that eliminates vibrations already at thirty percent surface coverage. The adhesive layer does not require heating during installation. The material retains flexibility over a wide temperature range from minus forty to one hundred seventy degrees Celsius.

Butyl Soundproofing Mats ABM Professional in the ABM Insulation store

The role of materials in absorbing sound energy

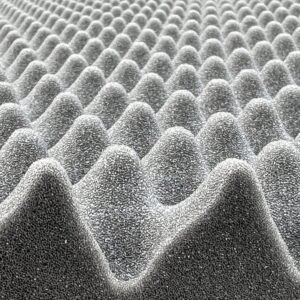

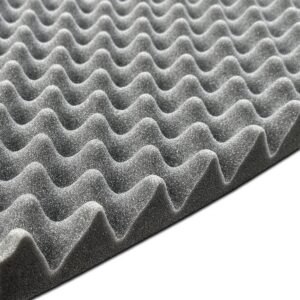

Absorbing sound energy fundamentally differs from damping vibrations. Acoustic waves penetrate the porous structure of the material, where they are scattered and converted into heat. Acoustic foam acts like a sponge for sound, trapping waves before they can reflect back.

The open-cell structure of absorbing foams increases the contact surface with sound waves. Acoustic energy is lost in countless reflections inside the microscopic cells of the material. The thicker the foam, the wider the frequency range effectively absorbed.

ABM acoustic foams are available in thicknesses from ten to fifty millimeters. Denser foam handles low frequencies more effectively. Profiled pyramid shapes increase the effective absorption surface of the material.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

The impact of echo reduction on sound perception in enclosed spaces

Echo in a car cabin is created by sound waves reflecting off hard surfaces. Sound reflects multiple times between windows, dashboard plastic, and metal elements. Reverberation blurs sound details, especially fast musical transitions.

Echo reduction shortens reverberation time in the cabin to a level close to that of a studio listening room. Music sounds more direct, without delayed reflections masking subtle recording elements. Absorbing foam on the ceiling and floor eliminates the longest acoustic reflection paths.

Surfaces requiring acoustic absorption:

- The cabin ceiling eliminates vertical reflections that disrupt sound spatiality

- The floor prevents low-frequency resonance in the lower part of the cabin

- The rear shelf in sedans dampens echo from the trunk space

- Side door panels absorb transverse reflections between left and right sides

- The rear side of the dashboard reduces echo from the front windshield

Composite materials combine vibration damping with sound absorption in one layer. Rubber foam with aluminum foil insulates both acoustically and thermally at the same time. The closed-cell structure does not absorb moisture or odors from the cabin.

Types of soundproofing materials and their specific applications

Modern soundproofing materials differ in chemical composition and intended use. Manufacturers develop specialized solutions for specific areas within a vehicle. Choosing the right type of material determines the effectiveness of the entire soundproofing process.

Comprehensive soundproofing requires using three basic categories of materials. Each performs a different function within the acoustic insulation system. Incorrect layering order or omission of any element significantly reduces effectiveness.

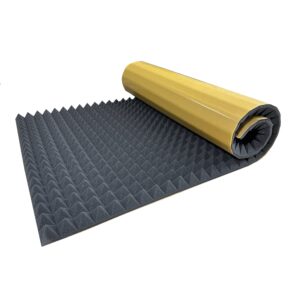

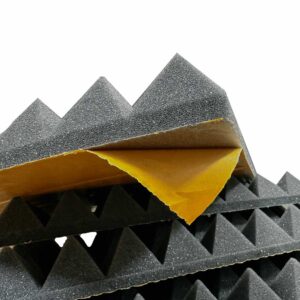

Butyl mats for eliminating structural vibrations

Butyl damping mats form the foundation of every soundproofing project. The self-adhesive layer facilitates installation without additional adhesives or heating. Aluminum foil on the surface reflects heat and increases overall structural stiffness.

ABM Xtreme premium-class mats do not contain asphalt, which cracks at low temperatures. The product retains flexibility throughout the vehicle’s service life. The manufacturer’s warranty covers five years of intensive use.

The thickness of the mats ranges from one point three to four millimeters. Thinner versions are suitable for doors, where every gram counts. Thicker sheets are installed on the floor and the central tunnel. The surface covered with the mat should constitute at least thirty percent of the total panel area.

Prices of ABM butyl mats:

- Small sheets from 0.75 EUR per single piece

- Professional roll half a square meter costs 12.50 EUR

- Professional roll two square meters priced at 29.25 EUR

- Xtreme series is twenty percent more expensive with better damping parameters

- Large orders over ten square meters with wholesale discount

Butyl Soundproofing Mats ABM Xtreme in the ABM Insulation store

Acoustic foams as a barrier against external noise

Acoustic foams absorb sounds passing through the sheet metal despite the use of damping mats. The open-cell structure traps sound waves and prevents their propagation into the cabin. The self-adhesive mounting layer speeds up installation in hard-to-reach places.

ABM foams are available in flat sheets and profiled pyramids. The pyramid shape increases the absorbing surface by up to one hundred fifty percent. The flame-retardant material meets strict safety standards in transportation.

A thickness of ten millimeters is sufficient to soundproof doors and ceiling. Twenty-millimeter foam eliminates echo in the trunk. The thickest versions, fifty millimeters, are used in campers and cargo spaces.

Prices of acoustic foams start at 3.50 EUR per sheet measuring fifty by fifty centimeters. One square meter of twenty-millimeter foam costs about 18.75 EUR. Versions with a self-adhesive layer are about twenty percent more expensive.

Mass vinyl used to block low frequencies

Mass vinyl is a heavier alternative to insulation foams. The material contains mineral fillers that increase mass without increasing thickness. Its high density blocks low-frequency noise that easily passes through lighter materials.

The mechanism works by reflecting and absorbing sound waves. Mineral particles inside the vinyl disperse acoustic energy. The material remains flexible despite its high surface mass.

The typical surface mass ranges from half to two kilograms per square meter. Thinner versions are used on doors, thicker ones on the cabin floor. Aluminum foil on the surface increases efficiency and protects against moisture.

Mass vinyl is installed between the damping layer and absorbing foam. It creates an effective acoustic barrier blocking road noise penetration. It performs particularly well with low frequencies from the engine and exhaust system.

Composite layers combining acoustic and thermal insulation

ABM insulating rubber foams combine soundproofing with thermal protection. The closed-cell structure does not allow air or water vapor to pass through. The material does not absorb moisture, preventing mold growth in hidden spaces.

Aluminum foil reflects radiant heat in both directions. In summer, it protects the interior from heating up; in winter, it retains heat inside the cabin. The adhesive layer ensures attachment to metal and plastic without additional glues.

The thickness of the rubber foam ranges from three to nineteen millimeters. Thinner versions are installed under the ceiling lining. Thicker sheets insulate the floor and engine partition.

Rubber foam is self-extinguishing and does not spread fire. It is resistant to oils and most chemicals used in automotive applications. It retains its insulating properties for many years of use.

Insulation Rubber Foams in the ABM Insulation store

ABM Rubber Foam. Acoustic Insulation Self-adhesive, 32mm, 0.5m2

Rubber Foam. Acoustic Insulation Self-adhesive ABM, 32mm, 1m2

Tip: Before purchasing materials, it is worth accurately measuring the surfaces intended for soundproofing and adding ten percent extra for cutting errors.

The impact of soundproofing on individual components of the audio system

The audio system consists of many components working together as a whole. Soundproofing affects each element of this system in a specific way. The improvement concerns not only the speakers but the entire acoustic characteristics of the cabin.

Quality sound enthusiasts often invest in expensive speakers and amplifiers. Without proper soundproofing, the potential of this equipment remains unused. A cabin full of noise masks the subtleties of music that costly equipment can reproduce.

Improvement of bass sound after applying door damping

Doors serve as natural enclosures for mid-bass speakers. Without damping, thin sheet metal vibrates along with the speaker membrane. Acoustic energy is wasted on vibrating large metal surfaces.

Soundproofed doors create a rigid enclosure similar to a professional speaker cabinet. The bass becomes stronger and more controlled. The low-frequency section gains precision without muddy booming that distorts the sound.

Effects of door soundproofing:

- Reduction of external door sheet vibrations by seventy percent

- Increase in bass power perceived inside the cabin without changing speakers

- Elimination of metal resonances disrupting low-frequency sound

- Improved separation between left and right stereo channels

- The ability to listen to music at lower volumes without losing bass quality

Installing butyl mats on the external door sheet reduces vibrations by up to seventy percent. The inner side of the door requires coverage with absorbing foam. Sealing technical openings with mass vinyl creates a closed acoustic space.

The effect is comparable to replacing speakers with a much more expensive model. Existing transducers operate under optimal conditions and realize their full design potential. The speaker membrane moves freely without wasting energy on body vibrations.

Greater clarity of high tones without environmental interference

High frequencies require silence inside the cabin for full perception of details. Wind and tire noise mask subtle sound elements such as cymbal rustling. Crackles and hisses from speakers get lost in overall travel noise.

Reducing noise by three to four decibels means a real decrease in sound intensity by half. High tones stop competing with external noises. The vocalist sounds clearer, and string instruments regain their natural tone.

The soundproofed cabin allows listening to music at lower volume levels. Less strain on the amplifier and speakers results in cleaner sound without distortion. Long trips become less tiring for the ears.

The improvement is especially noticeable when listening to classical and jazz music. These genres have a wide dynamic range and require silence for full appreciation. Studio recordings reveal details previously hidden in noise.

Change in the soundstage characteristics inside the cabin

The soundstage describes the spatial arrangement of instruments as perceived by the listener. In an uninsulated cabin, instruments sound flat, as if coming from a single point. Reflections from windows and plastics blur the natural positioning of sound sources.

Soundproofing creates a controlled acoustic environment resembling a listening room. Individual instruments are located in space according to the recording engineer’s intent. The depth of the stage allows distinguishing between closer and farther layers.

Elements improving the soundstage:

- Stereo separation between channels increases by thirty percent

- The vocal is precisely centered without blurring

- Accompanying instruments are spread to the sides according to the recording

- The depth of the stage allows distinguishing between foreground and deeper layers of music

- The height of sound sources becomes perceptually distinguishable after ceiling soundproofing

Absorbing materials on the ceiling eliminate top-down reflections that disrupt height perception of sources. A soundproofed floor prevents low-frequency resonance that distorts bass. A comprehensive approach to cabin acoustics yields results impossible to achieve by equipment replacement alone.

Tip: To fully appreciate the improvement in sound quality, it is worth testing the audio system before and after soundproofing using the same high-quality recording track.

Comparison of costs between DIY and professional soundproofing

The decision between doing it yourself or hiring specialists depends on many factors. Technical skills, tool availability, and time are key elements in this calculation. The final cost differs significantly between both approaches.

DIY soundproofing requires dismantling many interior components: doors, seats, dashboard, floor carpeting, and trunk panels. Each element must be carefully removed and reinstalled without damage.

Material expenses for different vehicle types

A compact car requires four to six square meters of butyl mats. The cost of ABM Professional materials ranges from 50 to 100 EUR. Absorbing foams add another 37 to 75 EUR.

A larger sedan or station wagon needs six to ten square meters of materials. The total cost of basic soundproofing ranges from 125 to 250 EUR. Comprehensive insulation with mass-loaded vinyl can reach 375 EUR.

SUVs and delivery vans require significantly larger amounts of material. The surface area to be covered reaches up to fifteen square meters. The budget for materials can exceed 500 EUR for complete soundproofing.

Professional service is priced based on the surface area and complexity of the work. Specialized workshops charge from 50 to 125 EUR per square meter covered with material. Complete soundproofing of a small car costs between 500 and 1,000 EUR in labor.

Time required to perform the work independently

Removing doors and panels takes from two to four hours for an experienced person. Applying damping materials takes another three to five hours. Reinstalling all components takes about the same amount of time as removal.

Complete soundproofing of four doors requires two days of weekend work. The floor and trunk require another full day of installation. People without experience should allocate twice as much time for each stage.

Schedule for DIY soundproofing:

- Day one: removal of all door panels and surface preparation

- Day two: application of butyl mats and foams in doors plus panel reinstallation

- Day three: removal of seats and floor carpeting with center tunnel

- Day four: soundproofing the floor and trunk with reinstallation of components

- Day five: acoustic tests and possible corrections in problematic areas

A professional workshop completes basic soundproofing within one working day. Comprehensive work lasts from two to three days. The client receives the vehicle ready for use without any personal involvement.

The value of one’s own time is an important part of the calculation. Two days of weekend work equals sixteen hours that could be spent on other activities. Financial savings must outweigh the value of this time for DIY execution to make economic sense.

Added value of professional installation by specialists

Specialists have experience in disassembling components without risking damage to clips and mounting points. They know typical pitfalls characteristic of different vehicle models. A warranty on completed work protects against potential problems in the future.

Professional installation ensures optimal placement of materials in the most effective locations. Specialists know where vibrations and noises concentrate for a given model. They avoid common mistakes made by amateurs that reduce soundproofing effectiveness.

The workshop has tools that facilitate pressing materials into hard-to-reach places. Pressure rollers and hot air guns speed up the work. A car lift provides convenient access to the floor and center tunnel.

The quality of workmanship affects the durability of the entire project. Poorly glued mats peel off after a few weeks of use. Unevenly distributed material creates local vibration points that worsen the final effect.

Tip: Before making a decision, it is worth asking a local workshop for a quote specific to your vehicle model and comparing it with the cost of materials plus the value of your own time.

Most Common Mistakes When Installing Soundproofing Materials

DIY soundproofing carries the risk of making mistakes that reduce the effectiveness of the entire project. Improper execution can even worsen the acoustic situation inside the cabin. Knowing typical errors helps avoid them during your own project implementation.

Enthusiasm for achieving silence often leads to excessive use of materials. Too many layers increase the vehicle’s weight without proportional improvement in sound insulation. A professional approach requires understanding automotive acoustics principles.

Incorrect selection of thickness and type of material for a given surface

A thick butyl mat on the doors adds pounds of weight, increasing fuel consumption. A thinner material with higher density provides better results with less weight. Areas exposed to strong vibrations require thicker damping layers.

Foams installed in moisture-prone areas deteriorate. Open-cell structure absorbs water and loses acoustic properties. In such locations, closed-cell rubber foam should be used.

Mass vinyl on the ceiling burdens the roof structure, increasing the risk of damage. Heavy material should be applied horizontally on the cabin floor. Lightweight foams are sufficient to soundproof the ceiling from above.

Composite materials combining multiple layers in one product simplify installation. Rubber foam with aluminum foil eliminates the need to apply a separate thermal barrier. Time savings compensate for the slightly higher price of the finished composite.

Neglecting key zones generating vibrations and noise

The central tunnel transmits vibrations from the exhaust system and driveshaft directly into the cabin. Skipping this area leaves the main source of low-frequency noise untreated. Soundproofing the tunnel yields measurable effects with minimal material use.

The engine firewall acts as a barrier between the hot, noisy engine and the cabin. An additional insulation layer significantly reduces mechanical noise from the engine compartment. Aluminum foil reflects heat, protecting the interior from overheating.

The most neglected zones:

- The central tunnel under middle seats transmits vibrations from the driveshaft

- The engine firewall allows mechanical noise and heat into the cabin

- Wheel arches in the trunk resonate from suspension and rolling tires

- Edges and folds of metal concentrate mechanical stresses and vibrations

- Technical openings in doors let sound through, destroying sealed enclosure effect

Wheel arches in the trunk resonate due to suspension vibrations and rolling wheels. These areas require special attention during material application. Thicker damping layers eliminate characteristic drumming from the rear part of the vehicle.

Edges and folds of metal generate most vibrations by concentrating mechanical stresses. Thorough coverage of these spots brings the greatest improvement with minimal material use. Professionals focus on strategic points instead of covering entire surfaces.

Neglecting Surface Preparation Before Material Application

A dirty or greasy surface prevents the adhesive layer from bonding permanently. The material peels off after a few weeks of use. Degreasing with isopropanol removes all residues that reduce adhesion.

Moisture under the glued material leads to hidden corrosion. Rust develops unnoticed, destroying the body sheet metal. All surfaces must be completely dry before installing insulation.

Old paint chipping off the inner door surfaces should be removed before gluing. The mat will stick to flaking paint instead of metal. A wire brush quickly prepares the surface for installation.

The temperature during application affects the adhesive properties of the material. Too low a temperature worsens adhesion, leading to later problems. Soundproofing should be done in a heated room or on warm days.

Incorrect Order of Applying Damping and Insulating Layers

Foam absorber applied directly to the metal does not eliminate mechanical vibrations. First, a butyl mat damping structural vibrations should be used. Only on a rigid base does foam effectively absorb sound waves.

Mass vinyl installed as the last layer loses effectiveness due to lack of mass above it. This material should be placed between the damping and absorbing layers. A three-layer sandwich provides the best comprehensive insulation results.

Aluminum foil facing the wrong way does not serve as a thermal barrier. Reflecting radiation requires proper orientation of the metallic surface. Aluminum should face the heat source.

An excessive number of layers increases mass without proportional improvement in soundproofing. Each additional layer yields less efficiency gain. Three layers of different types represent an optimal compromise between mass and effectiveness.

Tip: Performing a trial installation on a small area allows verification of technique and material adhesion before proceeding with full vehicle work.

FAQ: Frequently Asked Questions

Does car soundproofing affect fuel consumption?

Installing soundproofing materials increases vehicle weight by several kilograms, but its impact on fuel consumption remains minimal. The added weight causes fuel consumption to rise by only one to two percent. This effect is much smaller than differences caused by low tire pressure or aggressive driving style.

Comprehensive soundproofing of a compact car adds between 3.75 and 7.5 kilograms (EUR 0.25 conversion applied). Larger SUVs can gain up to 10 kilograms extra weight. The improvement in acoustic comfort and sound quality far outweighs this slight effect on fuel consumption. Most drivers do not notice any difference during everyday vehicle use.

How long do soundproofing materials retain their properties?

High-quality butyl mats maintain damping effectiveness throughout the vehicle’s lifespan. Butyl retains its flexibility and mechanical properties for twenty-five to forty years of use. The material does not dry out or harden despite fluctuating cabin temperatures. The only component requiring attention is the adhesive layer, which may weaken on vertical surfaces after many years. Properly installed materials do not lose mass or vibration damping ability over time.

Which areas of the car should be soundproofed first?

Priority soundproofing zones:

- Front doors improve speaker sound quality and reduce wind noise

- Cabin floor eliminates vibrations from suspension and tire rolling noise

- Wheel arches are the main source of road noise and stone impacts

- Center tunnel transmits vibrations from the exhaust system directly into the cabin

Doors and floor provide the greatest comfort improvement with moderate material use. Soundproofing these areas reduces noise by three to five decibels. The next stage should be the trunk and rear wheel arches. The ceiling and hood are less priority areas done at the end of the project.

Is DIY soundproofing difficult to perform?

Panel removal requires basic technical skills and access to instructions for the specific model. Applying materials is relatively simple when following the correct layer order. The most time-consuming step remains careful removal of parts without damaging mounting clips.

Key tools for DIY installation:

- A set of plastic trim removers for safe panel removal

- A utility knife for precise cutting of materials

- A roller for pressing out air bubbles under mats

- Isopropyl degreaser for preparing metal surfaces

Inexperienced individuals should reserve a full weekend to soundproof doors. A professional workshop will complete the same work within one business day. The choice between DIY and hiring specialists depends on the value of your own time and confidence in achieving a durable installation.

Does soundproofing completely eliminate cabin noise?

Total elimination of noise in a moving vehicle is not achievable. Soundproofing reduces sound intensity by three to ten decibels depending on the scope of work. A four-decibel reduction means an actual halving of noise intensity for the human ear. The effect is especially noticeable during high-speed highway driving, where wind and tire noise dominate an unsoundproofed cabin.

Comprehensive soundproofing creates an environment comparable to more expensive premium-class vehicles. Passenger conversations become comfortable without raising voices. The audio system operates at lower volume levels while maintaining full music clarity. Some mechanical sounds remain audible, but their intensity drops to an acceptable level that does not cause fatigue during long trips.

Summary

Car soundproofing is a real investment in the quality of music listening during travel. Eliminating external noises and body vibrations allows the audio system to operate under optimal acoustic conditions. The bass gains precision, the midrange sounds natural, and the treble reveals details previously masked by road noise.

A comprehensive approach requires the use of three types of materials working synergistically. Butyl mats dampen structural vibrations, foams absorb sound waves, and mass vinyl blocks low-frequency noises. The proper order of layer application and thorough surface preparation determine the durability and effectiveness of the entire project.

The choice between doing it yourself or hiring professionals depends on technical skills and available time. DIY soundproofing can cost from 75 to 375 EUR in materials with an investment of several hours of work. Professional service ranges from 500 to 1,500 EUR but guarantees optimal results and saves the vehicle owner’s valuable time.

Sources:

- https://www.sciencedirect.com/science/article/pii/S235214652300090X

- https://journals.sagepub.com/doi/full/10.1177/16878132251345867

- https://pmc.ncbi.nlm.nih.gov/articles/PMC9099554/

- https://www.ika.rwth-aachen.de/en/competences/fields-of-research/vehicle-dynamics-acoustics.html

- https://www.ibp.fraunhofer.de/en/expertise/acoustics/noise-control-vehicle-acoustics/vehicle-acoustics.html

- https://knaufautomotive.com/why-does-acoustics-in-cars-matter/

- https://en.wikipedia.org/wiki/Soundproofing

- https://pl.wikipedia.org/wiki/Izolator_akustyczny

- https://pl.wikipedia.org/wiki/Tuning_samochod%C3%B3w