Noise in the apartment has become a real plague of modern times. Sounds from the street, neighbors, or household appliances can effectively disrupt peace. However, soundproofing a room does not have to involve costly renovations or complicated construction work.

There are proven methods that significantly improve the acoustic comfort of any room. Self-adhesive materials, flexible foams, and modern mats allow for a quick transformation of any interior. Thanks to them, professional results can be achieved without much effort.

Anyone can carry out the process of soundproofing an apartment independently. All it takes is the right knowledge, appropriate materials, and a few hours of work. The effects will be noticeable almost immediately after installation is complete.

How Self-Adhesive Mats Turn a Room into Silence

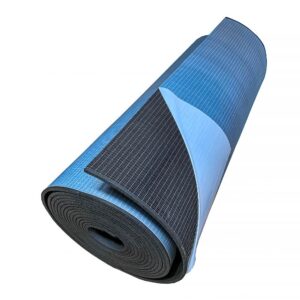

Self-adhesive mats represent a true revolution in home acoustics. These materials combine ease of installation with high effectiveness in sound dampening. Installation does not require specialized tools or technical knowledge.

Adhesive Technology in Soundproofing Mats

Modern mats use advanced acrylic adhesives. These substances provide a durable bond with any surface. The adhesive does not lose its properties over decades of use.

Room temperature is sufficient to activate the adhesive layer. The material adheres evenly without air bubbles forming. The surface does not require prior priming or preparation.

The flexibility of the adhesive allows for slight surface movements. The mat does not peel off during natural wall deformations. This system works especially well in older buildings.

Effectiveness in Dampening Various Frequencies

Self-adhesive mats best reduce mid-range sound frequencies. This range covers most household and urban noises. Conversations, music, and street traffic sounds are effectively muffled.

Types of sounds reduced by mats:

- Conversations through walls

- Footsteps from neighboring apartments

- Street noise from windows

- Sounds from televisions or radios

- Operation of household appliances

Low frequencies require thicker insulating materials. High tones are naturally dampened by most surfaces. Mats focus on the most troublesome acoustic ranges.

Combining several layers of mats increases system efficiency. Each layer reduces sound by additional decibels. A two-layer system can achieve a reduction of 15-20 decibels.

Areas with the Greatest Installation Effectiveness

Shared walls with neighbors require priority attention. Sounds most often penetrate through masonry structures. Installing mats over the entire surface yields the best results.

The area behind radiators is often neglected during insulation. This space acts as an acoustic bridge between rooms. Self-adhesive mats work perfectly in such places.

Optimal installation of soundproofing mats:

- Entire surfaces of shared walls

- Spaces behind radiators

- Areas around electrical outlets

- Wall sections near the bed

- TV mounting locations

Windows and doors require special attention during insulation. Frames act as natural acoustic bridges in the system. Sealing gaps significantly improves the overall system’s effectiveness.

Rubber foams as a multifunctional insulation solution

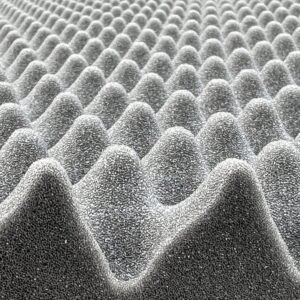

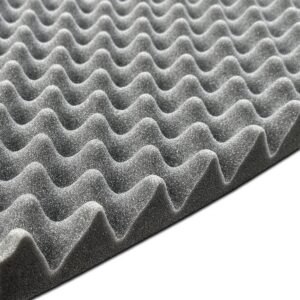

Rubber foams are characterized by exceptional flexibility and durability. This material perfectly adapts to irregular surfaces. The cellular structure ensures high efficiency in sound attenuation.

Physical properties of rubber foams

The foam’s cellular structure contains millions of tiny air bubbles. Each cell acts as a miniature acoustic damper. Sound loses energy as it passes through successive layers of the material.

The rubber’s flexibility allows installation in challenging locations. The material does not crack or break when bent. Operating temperature ranges from -40 to +80 degrees Celsius.

Advantages of rubber foams:

- High flexibility and durability

- Resistance to moisture and mold

- Ease of cutting and shaping

- Possibility of multiple reuse

- No emission of harmful substances

The foams do not absorb water nor lose properties in humid environments. The material does not provide a breeding ground for bacteria or fungi. Room hygiene remains at a high level throughout the entire usage period.

Application methods in various rooms

Bathrooms and kitchens require materials resistant to water vapor. Rubber foams perform perfectly under such conditions. The surface does not degrade due to high humidity.

Bedrooms and children’s rooms need safe insulating materials. Rubber does not emit volatile organic compounds. The air remains clean and safe for health.

Technical rooms often have irregular shapes and surfaces. The foam’s flexibility allows adaptation to any geometry. Installation is possible even in the most complex locations.

Closets or utility rooms require quiet operation of appliances. Foams reduce mechanical vibrations and oscillations. Washing machines or dryers operate significantly quieter after insulation is applied.

Selecting thicknesses of soundproofing materials for different needs

The thickness of the insulating material directly affects attenuation effectiveness. Thinner layers reduce high-frequency sounds. Thicker materials effectively dampen low tones and vibrations.

Analysis of room acoustic needs

Each room has unique acoustic characteristics. Size, shape, and furnishings influence sound propagation. A thorough analysis allows selecting the optimal material thickness.

Rooms with large volumes require thicker insulation layers. Sound has more space to spread out. Materials 10-20mm thick provide adequate noise reduction.

Small rooms, such as bathrooms or closets, need thinner solutions. Layers 3-5mm thick often suffice to achieve acoustic comfort. Thicker materials may unnecessarily reduce space.

Cost Optimization While Maintaining Efficiency

Thicker materials cost proportionally more. However, they do not always deliver significantly better results. A cost-benefit analysis helps make the right decision.

Material thicknesses for different applications:

- 3-5mm: basic insulation, small rooms

- 6-10mm: standard requirements, most rooms

- 11-15mm: high acoustic demands

- 16-20mm: professional studio applications

- Above 20mm: special industrial requirements

Combining different thicknesses in one room often yields better results. Areas with high noise exposure receive thicker layers. Other areas require basic insulation.

Gradation of thickness allows for even distribution of costs. The budget can be optimally used where the effects will be most noticeable. A strategic approach ensures maximum investment efficiency.

Tip: Before purchasing material, measure the noise level in different parts of the room. A phone app will show the areas that require the thickest insulation.

Soundproofing Without Heating Using Modern Technologies

Traditional acoustic insulation methods often required the use of high temperatures. Modern technologies eliminate the need for heating during installation. The process has become simpler and safer for home users.

Room Temperature Activation Systems

Self-adhesive materials use adhesives activated at low temperatures. The adhesive layer achieves full adhesion already at 68-72 degrees Fahrenheit. The process does not require additional surface heating.

Activation occurs through mechanical pressure during application. Proper pressing of the material triggers the bonding process. Full adhesion is achieved within 24-48 hours.

The cold-activated technology significantly simplifies the installation process. There is no risk of surface damage from high temperatures. Installation can take place under any weather conditions.

Safety of Use in Residential Spaces

The lack of heating eliminates fire hazards during installation. Materials do not emit toxic fumes when exposed to temperature. The process remains safe for children and elderly people.

Advantages of heating-free technology:

- No emission of harmful substances

- Possibility to work in enclosed spaces

- Elimination of burn risk

- Energy savings

- Simplicity of installation process

The materials maintain flexibility over a wide temperature range. Seasonal fluctuations do not affect insulating properties. The system performs equally well in summer and winter.

Installation can be done gradually, room by room. Residents do not have to leave their home during work. Daily life continues normally without major disruptions.

Tip: You will achieve optimal adhesion by pressing the material from the center toward the edges. Use a smooth roller or board to evenly distribute the pressure.

Materials for Effective Soundproofing at the ABM Insulation Store

ABM Insulation Store specializes in providing high-quality soundproofing materials. The offer includes a wide range of products tailored to various acoustic needs. Each material undergoes thorough quality testing before being made available for sale.

The company’s experience in the insulation industry guarantees proper guidance in selecting materials. Customers receive comprehensive information about product properties and application methods. The professional approach ensures achieving the expected soundproofing results in every project.

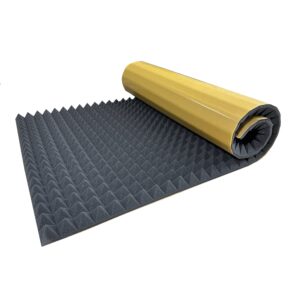

Rubber Insulation Foams

ABM Insulation offers a wide range of rubber foams with various parameters. The materials are characterized by high manufacturing quality and durability. Each product undergoes rigorous quality tests before being introduced to the market.

The foams are available in thicknesses from 6 to 50mm. The variety of dimensions allows tailoring the material to specific needs. The standard roll width is 1000mm, which minimizes the number of joints.

Rubber foam parameters:

- Thickness: 6-50mm in 3mm increments

- Standard width: 1000mm

- Roll length: 10-30 meters

- Operating temperature: -40°C to +80°C

- Fire reaction class: compliant with EU standards

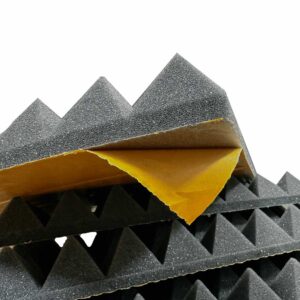

The foam surface can be smooth or have an adhesive layer attached. The self-adhesive option significantly speeds up installation. Materials without adhesive allow for proprietary mounting methods.

Insulation Rubber Foams in the ABM Insulation store

ABM Rubber Foam. Acoustic Insulation Self-adhesive, 32mm, 0.5m2

Rubber Foam. Acoustic Insulation Self-adhesive ABM, 32mm, 1m2

Sound Absorbing Acoustic Foams

Special acoustic foams are designed for maximum sound absorption. The material’s structure has been optimized to dampen specific frequencies. Efficiency exceeds standard insulation materials by 30-40%.

The foam surface can have various textures and shapes. Profiling increases the contact area with sound waves. Special patterns improve the acoustic properties of the entire system.

Acoustic foams are effective in home recording studios. Musicians and podcasters appreciate their effectiveness in eliminating echo. The materials do not alter the character of the sound but reduce unwanted reflections.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

ABM Professional Butyl Mats

The ABM Professional butyl mat line was created with demanding applications in mind. The mats contain an increased amount of butyl, which enhances damping properties. The material is ideal for areas with high noise exposure.

The thickness of the mats ranges from 1.5 to 4mm depending on the model. Each mat is covered with an aluminum layer that reflects heat. This solution prevents the material from overheating in sunny locations.

Specifications of ABM Professional mats:

- Butyl content: 35-50% depending on the model

- Aluminum layer: 50-100 microns

- Installation temperature: from -10°C to +50°C

- Adhesion: 15-20N/cm width

- UV resistance: full protection for 10 years

The Professional mats have a reinforced adhesive layer resistant to high temperatures. The system performs well even under direct sunlight. The material does not lose its properties during summer heat.

The mats work best on exterior walls and in places exposed to large temperature fluctuations. Their reinforced construction guarantees a long service life.

Butyl Soundproofing Mats ABM Professional in the ABM Insulation store

ABM Insulation Company

ABM Insulation Company is a reputable manufacturer and supplier of insulation materials based in Zabki near Warsaw. Since 2010, the company has continuously developed its operations, specializing in the production of high-quality butyl mats, rubber foams, and acoustic materials. Experience gained over more than a decade has enabled the creation of products characterized by exceptional effectiveness in thermal and acoustic insulation.

The ABM Insulation range covers a wide variety of applications—from soundproofing cars and apartments, through industrial insulation, to specialized solutions for yachts and campers. The company offers ABM Professional and ABM Xtreme butyl mats, insulating rubber foams, and sound-absorbing acoustic foams, all produced using modern technologies. Each product undergoes rigorous quality testing, ensuring property retention even under extreme temperature conditions.

Flexible Soundproofing Materials for Hard-to-Reach Places

Spaces behind radiators, in niches, or around pipes require special solutions. Standard insulation boards do not perform well under such conditions. Flexible materials perfectly conform to any shape.

Installation Techniques in Confined Spaces

Narrow spaces require modifications to standard installation techniques. The material should be cut to the appropriate dimensions beforehand. Flexibility allows for folding and fitting during application.

Access to the surface is often limited from one side. Self-adhesive materials eliminate the need to apply glue on-site. Simply peel off the protective film and press the material onto the surface.

Tools with extended handles make work easier in deep niches. Spatulas, rollers, or presses should be at least 30-40 cm long. Proper equipment significantly speeds up the installation process.

Utilizing the Properties of Flexible Materials

Flexibility allows for installing material in complex geometric configurations. Foams can be bent, twisted, and shaped to fit irregular forms. This property opens new possibilities in acoustic insulation.

Applications of flexible materials:

- Spaces behind heating installations

- Niches in structural walls

- Areas around cables and pipes

- Connections between walls and ceilings

- Device mounting points

The material can be scored and shaped as needed. Sharp tools allow precise cutting without damaging the structure. Flexibility is maintained even after mechanical processing.

Joining several pieces of material increases surface coverage. Overlapping edges by 2-3 cm ensures acoustic sealing. The system eliminates sound bridges at connection points.

Optimizing Surface Coverage

Planning the layout of the material before starting work saves time and resources. A room sketch with marked dimensions helps prepare appropriate pieces. Minimizing waste reduces overall project costs.

Irregular surfaces require an individual approach to each section. A cardboard template allows precise shape replication. Prepared patterns greatly facilitate cutting the material.

Cutting leftovers can be used in smaller spaces. Every piece of material has insulating value. Thoughtful resource management maximizes investment efficiency.

Tip: Start insulation from the most accessible areas, leaving difficult spaces for last. Gained experience will help better handle technical challenges.

Practical Tips for DIY Installation

Installing soundproofing materials yourself requires proper preparation and planning. The right tools and working technique ensure professional results. A methodical approach eliminates errors and saves time.

Surface and Tool Preparation

The installation surface must be clean, dry, and free of loose elements. Dust, grease, or paint can weaken material adhesion. Thorough cleaning guarantees a durable bond for years.

Essential tools for installation:

- Carpet knife with replaceable blades

- Measuring tape and pencil for marking

- Pressure roller or smooth board

- Spatula for gaps and corners

- Vacuum cleaner for surface cleaning

The room temperature should be at least 15 degrees Celsius. Lower temperatures may reduce the effectiveness of the adhesive layer. The optimal range is 18-25 degrees during installation.

The relative humidity should not exceed 70%. High humidity can cause condensation under the material. Proper conditions ensure a long service life of the system.

Order of insulation work

Installation should begin with the largest flat surfaces. Main walls require priority treatment due to efficiency. Small sections and details are left for the finishing stage.

The material is applied from top to bottom on vertical surfaces. Gravity helps evenly distribute the adhesive layer. This technique prevents folds and air bubbles.

Applying subsequent strips requires maintaining appropriate overlaps. The edges of the material should overlap by 2-3 cm. The connection ensures acoustic tightness of the entire system.

Quality control and finishing details

Each installed section requires adhesion testing. Gently pulling back an edge shows the quality of the bond. Poorly adhering areas should be pressed down further or replaced.

Gaps around windows, doors, or installations require special attention. Even small breaks in insulation can significantly reduce system effectiveness. Flexible materials work perfectly in such places.

Common mistakes during DIY installation:

- Insufficient surface cleaning

- Installation at too low a temperature

- Leaving air bubbles under the material

- Insufficient overlaps between strips

- Ignoring gaps and corners

The final inspection includes checking all joints and edges. Loose sections must be corrected immediately. Initial results can be expected just a few hours after completing installation.

Tip: Start work on a small, less visible section of the wall. This will allow you to master the technique before moving on to the main room surfaces.

Summary

Home soundproofing without renovation has become a realistic and accessible solution. Modern self-adhesive materials allow achieving professional results in a short time. Flexible rubber foams work excellently in hard-to-reach places, and a variety of thicknesses enable customization to individual needs.

No-heat technologies significantly simplify the installation process. Anyone can soundproof their apartment independently without specialized tools or technical knowledge. Products available at ABM Insulation store guarantee high quality and long service life.

An investment in soundproofing brings immediate benefits in increased living comfort. Silence and peace become everyday realities, not luxuries. Properly selected materials and careful installation ensure effects that last for decades.