Rising heating bills and environmental awareness are prompting homeowners to seek effective thermal insulation solutions. Polyurethane foams are revolutionizing construction by eliminating heat loss and reducing building operating costs. These materials act as a barrier against energy escaping through building partitions.

Energy efficiency is a key element of modern construction. Studies conducted by the Building Performance Institute Europe show the potential to reduce heat energy consumption by 40 percent through comprehensive thermal modernization. Heat loss in uninsulated buildings can reach up to 30 percent of total energy demand.

The use of modern spray foams changes the approach to thermal insulation. The material creates a seamless layer without joints or gaps where thermal bridges could form. Its tightness and low thermal conductivity coefficient make the building energy-efficient for decades of use.

Insulating properties of polyurethane foams and heat savings

The effectiveness of thermal insulation material depends on its ability to limit heat flow through building partitions. PUR polyurethane foam features parameters that surpass traditional insulation solutions. The material’s structure and application method determine the final tightness of the entire system.

The spray application method eliminates most problems encountered when installing panel materials. The foam fills every gap, reaches hard-to-access places, and adheres permanently to the substrate. Its closed-cell structure prevents moisture and air from penetrating through the insulation layer.

Low thermal conductivity coefficient as a key parameter of effectiveness

The lambda coefficient defines the thermal conductivity of a material. The lower its value, the better insulating properties the material has. Polyurethane foams achieve lambda values ranging from 0.022 to 0.028 W/(m·K). For comparison, mineral wool shows coefficients from 0.030 to 0.045 W/(m·K).

A low coefficient directly translates into space savings. A 10-centimeter-thick foam layer provides the same insulation as 15 centimeters of mineral wool. A thinner insulation layer means more usable room space or the ability to achieve better parameters with the same thickness.

Key features of closed-cell foams:

- Low water vapor permeability protecting the structure

- High compressive strength reinforcing building elements

- Durability of thermal parameters throughout the building’s lifecycle

- Waterproofing providing additional hydro insulation

- Rigidity eliminating material settling over time

The stability of the lambda coefficient throughout the material’s lifespan guarantees consistent insulation efficiency. Traditional materials lose their parameters over time due to settling or moisture absorption. The foam retains its original thermal properties regardless of operating conditions. A lower thermal conductivity coefficient directly translates into reduced heating energy demand for the building. Heat loss reduction through partitions reaches 50 percent compared to insulations with higher lambda values. Energy savings increase proportionally to the difference in coefficients between materials.

Elimination of thermal bridges in building structures

Thermal bridges are weak points in building partitions through which up to 30 percent of total heat energy escapes. They occur at joints of structural elements, around windows, balconies, and building corners. The temperature in these areas drops below the dew point, causing moisture condensation.

Spray foam creates a continuous, monolithic layer without seams or gaps. It reaches every nook of the structure, filling spaces inaccessible to board materials. The spray method eliminates the problem of thermal bridges at junctions of different building elements.

Applying foam on steel or wooden structures provides full thermal protection. The material adheres permanently to the substrate, leaving no gaps. The seamless insulation layer prevents cold spots on interior surfaces.

Sealing of the insulation layer preventing drafts

Leaks in building partitions cause significant heat energy losses. Air escaping through gaps carries heat away from heated rooms. Uncontrolled airflow causes discomfort for occupants and burdens heating systems.

Spray foams create a layer with 100 percent airtightness. In liquid form, the material penetrates the smallest holes, cracks, and joints of structural elements. After curing, it forms a monolithic barrier stopping air flow in both directions.

The insulation’s airtightness keeps indoor temperatures stable regardless of weather conditions. Eliminating drafts results in even heat distribution throughout all rooms. Mechanical ventilation systems with heat recovery can operate at maximum efficiency with sealed partitions.

Comparison of foam thickness with traditional insulating materials

Differences in lambda coefficients between materials determine the required thickness of the insulation layer. Achieving identical thermal resistance requires different thicknesses for various insulations. Polyurethane foam saves valuable space while maintaining high energy efficiency.

| Insulation Material | Lambda Coefficient W/(m·K) | Layer Thickness for R=5 m²K/W |

|---|---|---|

| Closed-cell PUR Foam | 0.024 | 12 cm |

| Open-cell PUR Foam | 0.037 | 18 cm |

| Mineral Wool | 0.038 | 19 cm |

| EPS Polystyrene | 0.040 | 20 cm |

| ABM Insulation Rubber Foam | 0.035 | 17 cm |

The table shows that closed-cell foam requires the thinnest layer to achieve a specified thermal resistance. The difference between foam and polystyrene is 8 centimeters for the same insulation effect. Space savings are important when insulating from the inside and insulating flat roofs.

Tip: Before choosing the insulation thickness, it is worth conducting thermal calculations of the building, taking into account the requirements of modern energy standards and long-term savings plans.

Use of foams in various building construction elements

Comprehensive thermal insulation covers all external partitions of the building. Each structural element requires adjustment of the application method and thickness of the insulation layer. Polyurethane foams are suitable for practically any place where heat loss occurs.

The versatility of the material results from its spray application capability and wide range of available densities. Closed-cell foam is suitable for insulating foundations and flat roofs. The open-cell version is used in attic and frame wall insulation. Flexibility in parameter selection allows optimizing the solution according to specific building needs.

Roof and ceiling insulation as protection against major energy losses

Warm air rises, so most heat energy escapes through the roof. An uninsulated attic can generate losses exceeding 35 percent of total heating demand. Effective roof insulation provides the fastest return on investment among all thermal modernization measures.

Spray foam applied under rafters creates a tight layer eliminating thermal bridges. The material adheres to wood, eliminating air gaps near the roof structure. The seamless method prevents insulation settling over time, maintaining full effectiveness for decades.

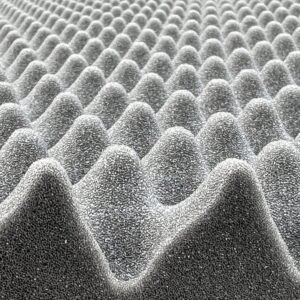

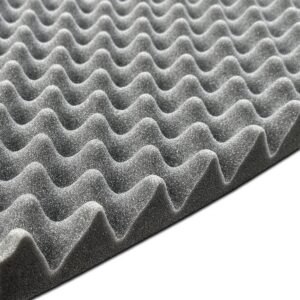

Insulating ceilings between floors improves acoustic and thermal comfort of rooms. ABM acoustic absorbing foam used on ceilings reduces sound transmission between floors. The thermal insulation layer above unheated basements protects against heat loss to the ground.

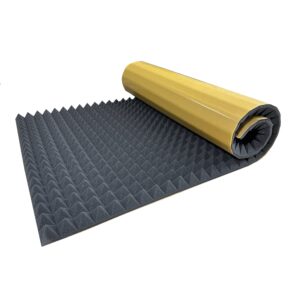

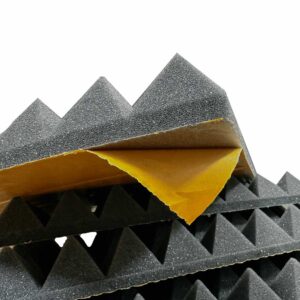

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

Insulation Rubber Foams in the ABM Insulation store

ABM Rubber Foam. Acoustic Insulation Self-adhesive, 32mm, 0.5m2

Rubber Foam. Acoustic Insulation Self-adhesive ABM, 32mm, 1m2

Spray insulation of exterior walls

Walls account for about 25 percent of heat loss in a typical single-family home. Exterior thermal insulation is an optimal choice, protecting walls from freeze-thaw cycles. Interior insulation is used in historic buildings or when facade intervention is not possible.

Applying foam to exterior walls by spray ensures complete airtightness of the insulation layer. The material fills wall irregularities, creating a perfectly smooth surface for plaster or cladding. Spraying foam into the cavity of a double wall is an effective method to insulate existing buildings.

Advantages of spray wall insulation:

- Complete filling of the space between the structure and cladding

- Elimination of thermal bridges around window and door openings

- Reinforcement of the stiffness of frame structures

- Short application time reducing the construction period

- No waste material minimizing disposal costs

Surface preparation of walls before spray application requires removal of loose elements and cleaning from dust. The substrate must be dry, stable, and free from substances that reduce material adhesion. Air and wall temperature should exceed 41 degrees Fahrenheit during application. Foam applied in layers 0.8 to 1.2 inches thick reaches a final thickness of 4.7 to 5.9 inches. Each layer requires partial curing before applying the next one. The process of applying the entire wall usually takes one working day for a standard single-family house.

Protecting foundations against heat loss to the ground

Foundations and basement walls are areas of significant heat energy loss. The soil surrounding the building acts as a heat absorber, drawing energy through the entire contact surface. Lack of foundation insulation causes cold floors on the ground level and moisture in rooms.

Closed-cell foam applied to foundation walls creates a waterproof thermal barrier. The material protects concrete from ground moisture and prevents structural freezing. Horizontal insulation under the ground floor slab eliminates heat loss through the foundation slab.

A layer of foam on external basement walls allows use of underground space as usable rooms. Temperature in insulated basements remains above dew point, preventing moisture condensation. Stable thermal conditions protect stored items and building technical installations.

Filling hard-to-reach spaces around installations

Installation passages through building partitions create gaps that serve as heat escape routes. Spaces around pipes, cables, and ventilation ducts often remain unfilled. Leaks during window and door installation generate drafts felt by occupants.

Aerosol polyurethane foam enables precise filling of the smallest gaps. The material expands, penetrating spaces inaccessible to traditional insulation. Using mounting foam when installing window joinery guarantees connection tightness.

Insulating spaces under bathtubs or showers with closed-cell foam protects against moisture condensation. Filling spaces between roof structure and chimney eliminates thermal bridging. Foam also secures installation passages through flat roofs, maintaining continuity of the thermal insulation layer.

Tip: When applying foam around electrical installations, use non-combustible materials or provide appropriate thermal shields in accordance with fire safety regulations.

The Impact of Thermal Insulation on Reducing Heating and Cooling Costs

Energy savings is the main reason for investing in comprehensive building thermal insulation. Heating and air conditioning bills constitute a significant part of property maintenance costs. Reducing energy consumption directly affects the household budget and the market value of the building.

Effective insulation reduces the heating power demand of the system, allowing for smaller equipment. Lower load on heating and cooling systems extends their lifespan and reduces maintenance frequency. Stable indoor thermal conditions improve residents’ comfort throughout the year.

Reducing energy consumption in the winter season by limiting heat loss

Uninsulated buildings lose most of the heat produced by heating systems. Heat losses force continuous operation of boilers or heat pumps, generating high bills. Thermal modernization with polyurethane foam reduces heating energy demand by 40 to 54 percent.

A tight insulation layer retains heat inside rooms longer. The heating system runs shorter, reaching the set temperature faster. Even temperature distribution across all rooms eliminates the need to overheat some zones of the building.

Areas with the greatest energy savings:

- Roof and flat roof reducing losses by half when properly insulated

- Exterior walls lowering demand by 25-30 percent

- Foundations and ground floors eliminating 15 percent of losses

- Sealing partitions reducing air infiltration by 20 percent

Practical energy savings become visible already in the first heating season after thermal modernization. The boiler or heat pump switches on less frequently, maintaining a stable temperature for longer periods. Reduced start-up cycles extend the lifespan of heating devices and decrease operational wear. Indoor temperature drops more slowly during heating breaks or occupant absences. The building acts like a thermos, storing heat generated by the heating system. It becomes possible to lower the temperature by one degree without losing thermal comfort. Each degree reduction means six percent lower heating costs annually.

Stabilizing indoor temperature in summer without excessive air conditioning

Effective thermal insulation protects not only against heat loss in winter but also against overheating in summer. Polyurethane foam forms a barrier against heat penetrating through roofs and walls. Indoor temperature rises more slowly during days with high outdoor temperatures.

Buildings with comprehensive insulation require less air conditioning power or may not need active cooling at all. A thick layer of foam on the roof prevents structural warming from solar radiation. Stable interior temperatures in summer translate into resident comfort and lower electricity bills.

Reducing the amplitude of daily temperature fluctuations inside the building improves living conditions. Rooms remain cool at night, allowing the body to regenerate during sleep. Avoiding excessive air conditioning use protects the health of residents and the natural environment.

Payback period for investment in polyurethane foam insulation

The cost of thermal modernization is a significant factor in deciding to carry out insulation work. The payback period depends on the scope of work, the initial condition of the building, and local energy prices. Comprehensive foam insulation typically pays off within 5 to 12 years.

Older buildings without any insulation provide the fastest return on investment. Reducing energy consumption by more than 50 percent results in tangible savings from the very first heating season. Rising energy carrier prices shorten the payback period every year.

Additional financial benefits include an increase in the market value of the property and a better energy class rating for the building. An energy performance certificate with a high rating facilitates selling or renting out an apartment. Low operating costs are a significant argument during price negotiations.

Financial savings amid rising energy carrier prices

Electricity, gas, and other fuel prices have been steadily increasing for years. Thermal modernization is an investment that protects against future price hikes affecting the household budget. Saving 40 percent on heating energy means a proportionally smaller impact from price increases.

An energy-efficient building allows for the use of renewable energy sources with lower capacity. Photovoltaic installations or heat pumps become more cost-effective with low energy demand. Combining effective insulation with eco-friendly heating systems leads to practical energy independence.

Stable property maintenance costs independent of energy market fluctuations provide a sense of financial security. Saved funds can be allocated to other life goals or further improvements in living comfort. Investing in insulation protects the financial value of the property for decades.

Tip: When calculating the payback period, consider not only direct energy savings but also increased durability of the building structure and improved quality of life that cannot be financially quantified.

Improving residents’ thermal comfort after thermal modernization

Residents’ thermal comfort depends not only on the average air temperature in rooms. Surface temperature of partitions, relative humidity, and air movement affect human thermal sensation. Effective insulation improves all parameters of the indoor environment.

Warm walls and ceilings eliminate the sensation of cold radiation from cool surfaces. The perceived temperature by residents rises despite maintaining a lower air temperature. The ability to lower room temperatures by 1-2 degrees without losing comfort generates additional energy savings.

Even Temperature in All Rooms of the Building

Buildings without insulation are characterized by large temperature differences between rooms. North-facing rooms remain cooler despite intensive heating. Spaces near exterior walls require radiators with greater power.

Comprehensive thermal insulation eliminates cold zones in the building. The temperature remains consistent in all rooms regardless of their location. Corner spaces and those near exterior walls become fully usable.

Areas of significant comfort improvement:

- Attic rooms achieving stable temperature throughout the year

- North-facing rooms balancing thermal conditions with the rest of the building

- Spaces near large glazing eliminating cold drafts

- Basement rooms suitable for comfortable use

Even temperature throughout the building allows flexible use of every room without restrictions. Furniture can be placed anywhere, including against exterior walls, without fear of cold. Children playing on the floor do not feel cold regardless of where they play. Bedrooms maintain a comfortable nighttime temperature without excessive heating of other rooms. Uniform thermal conditions eliminate the need to install additional heaters in problematic areas. Users stop avoiding cold zones in the building, gaining full access to the entire space. Savings also result from not having to overheat some rooms to warm others.

Elimination of Cold Walls and Moisture Condensation on Surfaces

Cold walls are a source of discomfort and moisture problems in the building. Surfaces with temperatures below the dew point accumulate condensing water vapor. Moisture promotes mold and fungi growth that threaten residents’ health.

The insulation layer raises the internal surface temperature of partitions above the dew point. Walls remain dry regardless of external weather conditions. Eliminating moisture protects the structure from damage and improves indoor air quality.

Dry walls mean no unpleasant musty odor or stains on plaster. Furniture can be placed directly against exterior walls without fear of dampness. A healthy indoor environment protects residents from respiratory diseases.

Acoustic Properties of Foam as an Additional Insulation Benefit

Polyurethane foam, besides excellent thermal parameters, also exhibits sound-dampening properties. The insulation layer reduces penetration of external noise into the building interior. Acoustic calm improves rest quality and concentration during work.

ABM acoustic absorbing foam used on interior walls eliminates echo and improves speech clarity. Insulation of inter-floor ceilings limits transmission of footsteps and conversations. Acoustic comfort inside is an important element of residents’ quality of life.

Buildings located on busy streets particularly benefit from the sound-absorbing properties of foam. A thick layer of insulation on exterior walls reduces traffic noise by 30-40 decibels. A quiet indoor space promotes body recovery and effective mental work.

Tip: When designing room acoustic insulation, it is worth considering the use of ABM Insulation rubber foam characterized by high sound absorption parameters and flexibility that facilitates installation.

Durability of thermal insulation solutions and their environmental impact

An investment in building insulation should serve for decades without the need for replacement or repair. The durability of the thermal insulation material determines the actual economic and ecological profitability of the entire project. Polyurethane foam maintains its parameters for at least 50 years of use.

The impact of thermal insulation on the natural environment goes beyond energy savings during building operation. Production, transport, and disposal of the material also generate a carbon footprint. The ecological balance of polyurethane foam remains favorable due to long-term use and significant reduction in carbon dioxide emissions.

Foam resistance to weather conditions over decades of use

Insulation materials are exposed to temperature, moisture, and ultraviolet radiation. The closed-cell structure of PUR foam prevents penetration of water and water vapor. The material does not absorb moisture, maintaining full insulation effectiveness regardless of weather conditions.

The foam does not undergo chemical aging or biological degradation. The material does not serve as a nutrient for microorganisms, mold, or fungi. Resistance to temperatures from minus 50 to plus 100 degrees Celsius ensures parameter stability in any climate.

Factors affecting insulation durability:

- Quality of application determining adhesion to the substrate

- Protection against direct UV radiation extending lifespan

- Ventilation of partitions preventing moisture accumulation

- Operating temperature within the allowable range

Extreme weather conditions occurring in the Polish climate do not negatively affect the foam structure. Freezing and thawing cycles do not cause cracks or loss of insulating properties. The foam retains flexibility at subzero temperatures, does not crumble or chip off the substrate. Summer heat reaching 40 degrees Celsius does not degrade the cellular structure or reduce thermal efficiency. Laboratory tests confirm chemical stability of the material through a minimum of 50 freezing cycles. Actual lifespan often exceeds 80 years under typical residential building operating conditions.

Reduction of carbon dioxide emissions through lower heating demand

Burning fossil fuels in heating boilers and power plants generates carbon dioxide responsible for global warming. Reducing energy consumption directly translates into lower greenhouse gas emissions. Studies show the possibility to reduce a building’s carbon footprint by half through comprehensive thermal modernization.

Polyurethane foam saves a hundred times more energy throughout its entire service life than was used to produce it. The material’s energy balance becomes positive after just a few years of use. Every ton of saved heating oil eliminates the emission of about 3 tons of carbon dioxide into the atmosphere.

Energy-efficient buildings enable the achievement of the European Union’s climate goals, which aim for carbon neutrality by 2050. The thermal modernization of the existing housing stock is a key element of the emission reduction strategy. Every insulated building contributes to climate protection for future generations.

Proper selection of layer thickness for maximum energy efficiency

The insulation thickness should result from the building’s heat balance calculation and legal requirements. The minimum thickness specified by standards serves as a starting point but does not always guarantee optimal efficiency. Increasing the layer above the minimum brings additional energy savings.

An economic analysis should consider material costs, labor, and the value of saved energy in the long term. The optimal point usually lies above the minimum regulatory requirements. A foam thickness of 15-20 centimeters on the roof and 12-15 centimeters on the walls provides excellent efficiency.

| Building Element | Minimum Foam Thickness | Recommended Thickness | U-Value After Insulation |

|---|---|---|---|

| Roof | 18 cm | 22 cm | 0.12 W/(m²K) |

| Exterior Walls | 12 cm | 15 cm | 0.18 W/(m²K) |

| Ground Floor | 10 cm | 14 cm | 0.20 W/(m²K) |

Excessive insulation thickness does not always mean better energy efficiency of the building. An overly thick layer can cause problems with water vapor diffusion through the partitions. The optimal thickness depends on the energy standard of the designed building. Low-energy houses require a layer of 18 to 22 centimeters on the roof. Passive buildings need even 30 centimeters of foam to meet strict standards. Local climatic conditions significantly influence the choice of insulation parameters.

Cost-effectiveness calculations should consider rising energy prices over a 30-year perspective. An additional 5 centimeters of foam increases the cost by 15 percent, reducing heat loss by another 20 percent. The investment in a thicker layer pays off within 8 to 12 years. Designers should perform computer simulations of the heat balance before making a final decision. An individual approach to each building guarantees maximum efficiency with reasonable financial outlays. Professional thermal calculations eliminate the risk of overinvestment or insufficient insulation.

Mold and moisture protection as an element of healthy construction

Moisture in building partitions leads to the development of microorganisms harmful to residents’ health. Mold releases toxins and allergens that cause respiratory diseases. A healthy building ensures dry partitions and proper air exchange.

Tight foam insulation raises the temperature of internal partition surfaces above the dew point. Water vapor condensation cannot occur on warm walls. The closed-cell structure of the material acts as a barrier to moisture migration through partitions.

Controlled mechanical ventilation complements effective insulation, ensuring proper indoor air quality. Relative humidity maintained below 60 percent prevents mold growth. A healthy living environment protects residents’ well-being and physical condition throughout their lives.

Tip: Comprehensive thermal modernization should include not only partition insulation but also ventilation modernization that ensures proper air exchange in a tight building according to residents’ health requirements.

FAQ: Frequently Asked Questions

How long does polyurethane foam insulation remain effective?

Polyurethane foam retains full insulating properties for over 50 years of use. Studies conducted on old installations confirm the stability of thermal parameters over decades. The material has not settled, changed its structure, or thermal conductivity coefficient. The closed-cell foam structure protects against moisture penetration and biological degradation. The durability of insulation often exceeds the lifespan of other building elements such as roofing or facade.

Main factors ensuring longevity: proper application by qualified contractors, protection from direct UV exposure, appropriate ventilation of building partitions, and operating temperature within manufacturer-recommended limits. Foam does not require replacement or repairs after 25 years of use. Investing in foam thermal insulation is a lifetime solution for the building.

Does thermal insulation foam require special maintenance after application?

Properly applied polyurethane foam practically requires no maintenance during use. The material retains its properties without the need for servicing or repairs. Only routine visual inspections every few years are recommended. These inspections involve checking for cracks, discoloration, or mechanical damage to the insulation layer.

Periodic inspection elements: checking the contact points of the foam with various building materials, inspecting areas exposed to direct sunlight, verifying the absence of moisture or condensation traces, and assessing the overall condition of the insulation surface. Inspections are best conducted in spring and autumn. If the insulation layer remains intact, no action is necessary. Mechanical ventilation systems require regular servicing regardless of the foam’s condition.

What is the optimal foam thickness for different parts of a building?

The thickness of the insulation layer depends on its location within the building and energy requirements. The roof requires the thickest layer due to the greatest heat loss in that area. The optimal foam thickness in attics ranges from 18 to 25 centimeters. Studies show a 97 percent reduction in heat flow with a 20-centimeter layer. Exterior walls require a layer of 12 to 15 centimeters to meet current standards.

Recommended thicknesses for structural elements: roofs and flat roofs 20 to 30 centimeters depending on climate, exterior walls 12 to 18 centimeters according to energy standards, ground floors 10 to 15 centimeters eliminating heat loss to the earth, and foundations 8 to 12 centimeters protecting against freezing. Passive houses may require up to a 30-centimeter layer on the roof. Excessive thickness limits vapor permeability of partitions. Parameter selection should consider building specifics and local climate.

Can foam be used in older buildings requiring renovation?

Polyurethane foam works excellently for renovating old buildings. The spray method allows insulating irregular surfaces, arches, and vaults characteristic of historic architecture. The material fills gaps, cracks, and voids in old walls without needing surface leveling. The foam’s lightweight structure does not burden weakened building structures. Interior insulation saves historic buildings where facade changes are not allowed.

Open-cell foam allows water vapor to pass through, preventing dampness in old walls. Spray technology reaches hard-to-access places between beams or in roof spaces. Benefits for old houses: elimination of thermal bridges at joint locations, sealing leaky partitions reducing drafts, strengthening weakened structures by increasing rigidity, and protection against further moisture-induced degradation. Foam-based thermal modernization restores comfort and lowers bills in historic buildings.

How soon after foam application can further construction work continue?

The drying time of the foam depends on its type and weather conditions. Closed-cell foam hardens within 24 to 48 hours. The open-cell layer requires 24 to 72 hours to fully cool. Temperature and humidity affect the speed of the process. After six hours, the foam achieves sufficient stability for light work.

Safe entry into the room is possible 12 to 24 hours after application. Thorough ventilation of the space is necessary before starting further activities. Stages after insulation application: initial material hardening within the first hour, expansion and dimensional stabilization over the next 6 hours, achieving full mechanical strength after 24 hours, and complete chemical curing after 48 to 72 hours. The process can be accelerated by lightly moistening the surface with water. Thicker layers require longer drying times than thin ones. Manufacturers provide precise recommendations for specific products.

Summary

Thermal insulation foams are a fundamental element of energy efficiency in modern buildings. Low thermal conductivity, airtight application, and material durability ensure long-term energy savings. Reducing heating energy consumption by 40-50 percent directly translates into lower bills and a reduced carbon footprint for the building.

Comprehensive thermal modernization covering all external partitions brings the greatest financial and ecological benefits. Insulating roofs, walls, and foundations eliminates thermal bridges and drafts. Uniform temperature in all rooms, absence of moisture, and quiet indoor space improve residents’ quality of life.

Investing in polyurethane foam insulation pays off within a few years, serving the building for decades afterward. Rising energy prices and climate protection requirements make thermal insulation an economic and social necessity. Every insulated building contributes to reducing greenhouse gas emissions and protecting the planet’s natural resources for future generations.

Sources:

- https://www.sciencedirect.com/science/article/pii/S277268352400058X

- https://enerad.pl/raport-miwo-termomodernizacja-budynkow-w-polsce-obnizy-straty-energii-o-40/

- https://www.recticelinsulation.com/en-gb/understanding-thermal-bridging-what-it-and-how-prevent-it