Soundproofing the floor of a car improves acoustic comfort while driving. The floor allows outside sounds to pass through, such as tire noise, aerodynamic noise, and powertrain noises. Well-made sound insulation can reduce the noise level in the cabin by up to several decibels, which increases travel comfort.

The soundproofing process requires proper surface preparation and the use of specialized materials. A combination of butyl mats and rubber foams is used. Butyl mats dampen low frequencies and vibrations, while rubber foams absorb higher frequency sounds.

The effects of soundproofing are noticeable immediately after the work is completed. Noise reduction improves driver concentration, reduces fatigue during long journeys and improves the sound quality of the audio system. Soundproofing materials also act as thermal insulation, which ensures better thermal comfort in summer and winter.

Why is it worth soundproofing the car floor?

Soundproofing the car floor has many advantages that improve the comfort of using the vehicle. The floor is one of the largest surfaces through which noise penetrates. Effective sound insulation significantly increases driving comfort.

Improving road safety

Excessive noise in the cabin can be dangerous. Loud noises from the environment distract the driver. Engine noise, traffic and the noise of other vehicles increase stress and fatigue.

Soundproofing the floor reduces these noises, which makes it easier to concentrate. Studies show that long-term exposure to noise can cause temporary hearing impairment and slower reactions. This has a direct impact on the speed of response in emergency situations.

A quieter interior reduces fatigue on long journeys. This allows concentration to be maintained at a higher level for a longer period of time.

Protection of the body against corrosion

Soundproofing materials also protect the body. Moisture and dirt can accelerate corrosion. Waterproof insulating layers protect the metal from rust and increase the vehicle’s lifespan.

Additional insulation protects the construction from the harmful effects of weather conditions. This is particularly important in autumn and winter when roads are salted. Protecting the floor from corrosion helps maintain the vehicle’s value for longer.

Optimizing the microclimate

Soundproofing materials also act as thermal insulation. They help maintain the right temperature in the cabin. In winter, the interior stays warmer and in summer, cooler.

Better thermal insulation contributes to

- a more comfortable temperature being reached more quickly,

- lower energy consumption for heating or air conditioning,

- better fuel efficiency of the vehicle.

Studies show that proper insulation can reduce fuel consumption by 5-10%. On cold days, fuel consumption increases by up to 41%, and air conditioning in summer can reduce fuel economy by more than 25%.

Tip: Before soundproofing, it is worth doing a test. Measure the time needed to reach a comfortable temperature in winter and summer. After soundproofing, you can measure again to assess the effectiveness of the insulation.

Sources of noise penetrating through the car floor

The car floor is the main surface through which noise enters the vehicle interior. Understanding its sources enables more effective soundproofing of the cabin and improved driving comfort. Noise penetrating through the floor can be divided into several main categories.

Noise generated by tires

The contact between tires and the road surface is one of the main sources of noise in a car. Vibrations and sounds of different frequencies are produced while driving.

Their intensity depends on several factors:

- the type and condition of the road surface,

- the type and wear of the tread,

- the tire pressure,

- the driving speed.

Studies show that increasing the speed from 50 to 100 km/h can increase the noise level generated by tires by 9-12 decibels. These sounds penetrate the interior, especially around the wheel arches and the luggage compartment.

Vibrations of the drive system

The engine, gearbox and exhaust system generate vibrations that are transferred to the floor. The vibrations are felt especially in the front part of the cabin, near the center tunnel and under the front seats. Their character depends on:

- engine speed,

- vehicle load,

- technical condition of components.

Vibrations often have low frequencies that can cause the bodywork to resonate. This manifests itself as a characteristic “rumbling” in the cabin.

Aerodynamic noise

At higher speeds, the airflow around the vehicle has a major impact on the noise level. Although most of the noise is transmitted through the windows and door seals, some also penetrates through the floor. The turbulence generated under the vehicle produces mid and high frequency sounds. These are particularly noticeable in places where there are bumps and technological openings in the chassis.

Tip: Before soundproofing the floor, it is worth conducting a test. Ask an assistant to hit different places on the underbody while listening to the sounds inside the cabin. This will help identify the areas through which the noise penetrates the most.

Preparing the car floor surface for soundproofing

The correct preparation of the floor is a crucial stage of soundproofing. The quality of this process affects the durability and effectiveness of sound insulation. Errors can lead to the detachment of materials, corrosion under the insulation layer and a decrease in soundproofing efficiency.

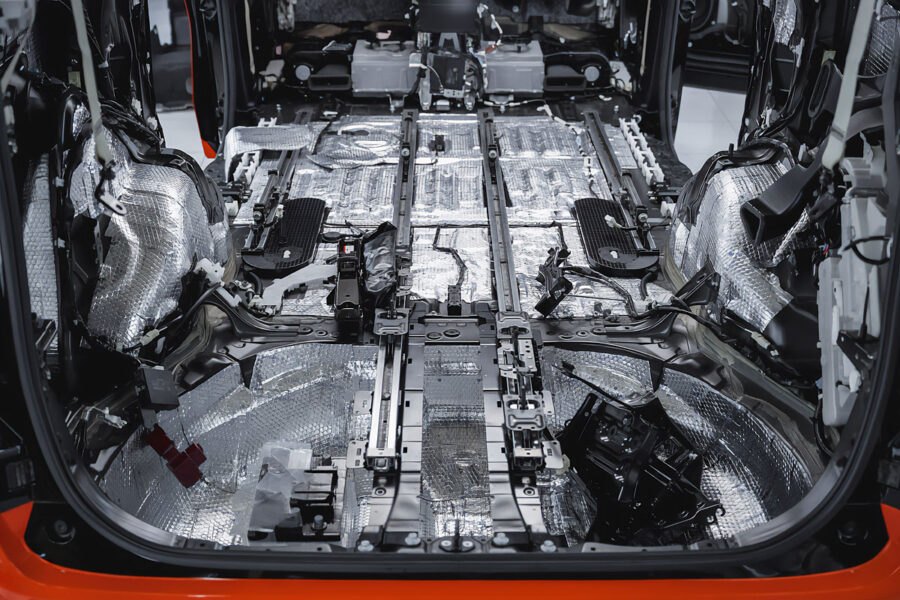

Dismantling interior elements

The first step is to remove the components that block access to the floor. The process requires a systematic approach and proper preparation of the workspace. The following should be removed:

- front seats and rear bench,

- center console and controls,

- floor carpet,

- the sills and covers,

- the trunk upholstery.

It is a good idea to take photos during disassembly to make reassembly easier. Be careful when disconnecting wiring harnesses and cables to avoid damage.

Dismantling gives you the opportunity to thoroughly vacuum the interior. It also makes it easier to find small objects that may have fallen under the seats or console. This is a good time to thoroughly clean hard-to-reach areas.

Cleaning and rust removal

After dismantling, thoroughly clean the metal floor surface. The process involves several steps:

- Remove loose dirt with an industrial vacuum cleaner.

- Wash the surface with warm water and detergent.

- Dry the floor thoroughly to prevent corrosion.

Pay special attention to rusty areas. Clean them mechanically with a wire brush or sandpaper. After removing the rust, apply a rust inhibitor.

Tip: Use methylated spirits or isopropyl alcohol instead of petroleum spirit to degrease surfaces. These substances evaporate faster, do not leave a greasy film and are safer in confined spaces.

Degreasing surfaces

The last step of preparation is thorough degreasing. This step affects the adhesion of soundproofing materials. Even a small amount of grease can weaken the bond strength of the adhesive.

It is best to use preparations that evaporate quickly and leave no residue. The surface should be wiped with clean, lint-free cloths, replacing them with new ones after each section of the floor.

Particular attention should be paid to the area around the center tunnel, the seat mounting area, and the pedal areas. These areas often require several degreasing sessions.

After degreasing, it is best to wait a few minutes to allow the product to evaporate completely. Only then can you start applying soundproofing materials.

Application of ABM Professional and Xtreme butyl mats on the floor

Butyl mats are a key element of effective soundproofing of a car floor. ABM Professional and Xtreme products are distinguished by high quality and excellent sound and vibration damping properties. Correct application of these materials improves the acoustics of the interior, ensuring a quieter and more comfortable ride.

Characteristics of ABM butyl mats

ABM Professional and Xtreme mats consist of a layer of pure butyl combined with aluminum foil. This design ensures effective noise reduction and thermal insulation. A 2.5 mm thick ABM Professional mat weighs approximately 9 kg per roll measuring 50 cm × 400 cm. The material has a high MLF vibration damping coefficient of 0.38.

ABM Xtreme mats are an improved version of standard mats, offering even better sound damping performance. They are recommended in places requiring maximum noise reduction, such as the floor under the seats or around the center tunnel.

The main advantages of ABM butyl mats:

- flexible structure prevents cracking,

- water and oil resistant,

- no need to heat during installation,

- effective thermal insulation,

- operating temperature range from -50°C to +120°C,

- non-toxic composition.

Butyl mat application technique

There are a few rules to follow for the correct installation of butyl mats. The process starts with cutting the material to the right shape. ABM Professional and Xtreme mats can be easily cut with a box cutter or scissors.

Start applying the mat in the middle of the floor and gradually move towards the edges. Use a mounting roller to press the mat firmly against the sheet metal. ABM offers metal and polyurethane rollers to help you adapt the material to the shape of the floor.

Special attention should be paid to the joints between the mats. It is recommended to overlap them by 1-2 cm to eliminate acoustic bridges. It is also important to precisely cut off the excess material around the mounting holes.

Tip: Before applying the butyl mats, it is worth warming them up slightly with a hair dryer. This increases the flexibility of the material and makes it easier to adjust to uneven floors.

Differences between ABM Professional and Xtreme mats

ABM Professional and Xtreme mats differ in several key parameters. ABM Professional is a basic soundproofing material, suitable for most applications.

ABM Xtreme mats have a higher density and better sound absorption properties. They are recommended for areas particularly exposed to noise and vibration, such as the floor under the seats and the center tunnel.

Xtreme mats also have a thicker butyl and aluminum foil layer, which improves thermal insulation. The increased thickness of the aluminum foil (0.1 mm – 100 μ) provides better protection against noise and temperature.

The optimal solution is to use both types of mats: ABM Xtreme in areas exposed to intense vibrations and ABM Professional on other surfaces. This combination allows you to achieve the best soundproofing effect at a reasonable cost.

Use of ABM self-adhesive rubber foam as a second layer

ABM self-adhesive rubber foam is an effective addition to the car floor soundproofing system. Applied as a second layer on top of the butyl mats, it creates a complete sound insulation. The combination of these materials provides better protection against noise penetrating through the floor.

ABM rubber foam properties

ABM foam rubber has a cellular structure that absorbs medium and high-frequency sounds. The material is available in thicknesses from 13 mm to 25 mm, which allows you to choose the right variant for the needs of a particular vehicle.

Main features of ABM foam rubber:

- flexible structure that adapts to uneven surfaces,

- resistance to moisture and water vapor,

- effective thermal insulation,

- non-flammability and safety of use,

- self-adhesive layer for easy installation.

ABM foam not only absorbs sound, but also improves thermal insulation. It keeps the heat in on cold days and protects against overheating in summer.

Application process of rubber foam

Installing ABM rubber foam requires precision. The process starts with cutting the material to size. The foam can be easily cut with a knife or scissors.

Before applying the foam, make sure that the surface of the butyl mats is clean and dry. Dirt can weaken the adhesion. After cutting the foam, remove the protective film of the adhesive layer and stick the material carefully to the butyl mat.

The foam should be applied without any overlaps. The elements must fit together well to avoid gaps. After applying the foam, press it gently, starting from the center and moving towards the edges. This application method prevents the formation of air bubbles.

Application of foam in different floor areas

ABM 13 mm foam rubber is suitable for standard applications. It works well on most floor surfaces where noise is not extremely high. In areas particularly prone to sound transmission, such as the area above the wheel arches or the center tunnel, 25 mm foam is a better choice.

ABM foam rubber is best used in the following areas:

- under the front seats – reduces engine noise,

- around the center tunnel – minimizes vibrations from the drive train,

- trunk floor – reduces noise from the wheels and exhaust system,

- area under the rear seat – reduces noises from the fuel tank.

Tip: When installing ABM foam rubber on curved surfaces such as the center tunnel, it is helpful to make cuts every few centimeters. This will make it easier to fit the foam to complex shapes without folds and creases.

Tips for installing and maintaining soundproofing

Correct installation of soundproofing materials is crucial for effective sound insulation of the car floor. Even the best materials will not provide the expected results if they are installed incorrectly. Proper installation techniques and regular maintenance will keep the soundproofing effective for a long time.

Prepare tools and work area

Before starting the installation, gather the necessary tools and prepare the work area. Basic equipment includes

- a sharp box cutter or scissors for cutting materials

- an assembly roller for pressing mats and foams

- a degreasing agent for surface preparation

- clean, lint-free cloths,

- protective gloves (the edges of aluminum foil can be sharp),

- tape measure and pencil for marking dimensions.

The workplace should be well lit and ventilated. The optimal installation temperature is 18-25°C. At lower temperatures, the adhesive may not adhere properly, and at higher temperatures, the materials may become too soft and difficult to work with.

It is a good idea to take photos of the interior elements before disassembling them. The photos will make it easier to reassemble them later. It is best to store screws and fasteners in labeled containers.

Assembly techniques for durability

For effective soundproofing, the materials must adhere to the floor. Leaving air bubbles or not pressing the edges down properly can reduce the effectiveness of the insulation.

When applying butyl mats, you should

- press the material down firmly with a roller, starting from the center and moving towards the edges,

- carefully finish the edges to prevent them from peeling off,

- avoid excessive stretching, which can cause cracking,

- precisely cut holes for mounting elements.

When installing foam rubber, it is crucial to:

- distribute the material evenly without folds and creases,

- make sure the edges of adjacent pieces fit together precisely,

- avoid excessive compression, which could reduce the insulating properties.

After finishing the installation, it is worth checking the soundproofing for leaks before reassembling the interior elements. Make sure that all edges are pressed down well and that there are no places where the material could come loose.

Tip: When installing on curved surfaces, such as the center tunnel, it is a good idea to make cuts every few centimeters. They should only cover the foam layer without damaging the adhesive layer. This will make it easier to adjust the material to complex shapes.

Maintenance and inspection of the soundproofing

Soundproofing materials require periodic inspection and maintenance, despite their high durability. Regular checks of the insulation status allow for the detection of potential problems and the prevention of major damage.

Basic maintenance activities include:

- checking the edges for detachment,

- inspecting materials in areas exposed to moisture,

- evaluating the effectiveness of the soundproofing by listening for unwanted sounds.

If there are any loose parts, they should be reattached or replaced. The area around the wheel arches requires special attention because moisture can weaken the adhesion of the materials.

Soundproofing materials lose their effectiveness over time. The average lifespan is 8-10 years. After this time, it may be necessary to renew the soundproofing partially or completely.

A systematic inspection should be carried out at least once a year, preferably before the winter season, when the vehicle is most exposed to moisture and road salt.

FAQ: Frequently asked questions

What materials are best for soundproofing a car floor?

Butyl mats and rubber foams are best suited for soundproofing a car floor. Butyl mats are flexible and effectively dampen vibrations and noise. Their resistance to moisture and temperature changes makes them well suited for various road conditions.

The rubber foam used as a second layer absorbs high-frequency sounds, increasing the effectiveness of sound insulation. Modern materials have replaced the old felt and bitumen mats, which were heavy, prone to cracking and absorbing water.

What are the benefits of effective soundproofing for a car floor?

A well-soundproofed floor improves the acoustic comfort in the vehicle interior. Noise reduction reduces driver and passenger fatigue and improves concentration, which improves driving safety.

Soundproofing materials also act as a thermal barrier. They reduce the transfer of heat and cold, which lowers energy consumption for heating or air conditioning. Better acoustics also improve the sound quality of the audio system, which music lovers will appreciate.

How do I properly soundproof the floor of a car?

The soundproofing process begins with the removal of the seats, the bench, the center tunnel and the carpet. Then the floor surface should be cleaned and degreased with a specialized preparation.

Butyl mats are applied to the prepared surface, adjusting them to the shape of the floor and cutting holes for the mounting elements. It is important to press down firmly with a roller to avoid air bubbles.

After installing the butyl mats, a layer of rubber foam is applied, which further absorbs sound. The final step is to reinstall the interior elements.

Does soundproofing the floor of a car affect its weight?

Adding insulation materials increases the weight of the vehicle, but modern butyl mats and rubber foams are lightweight and highly effective. The increase in weight is minimal and does not significantly affect performance or fuel consumption.

Previously used felt and bitumen mats were much heavier and less effective. Modern solutions provide better soundproofing without excessive vehicle weight.

How to take care of the soundproofing of the car floor?

Soundproofing materials are durable and resistant to external factors, but they require periodic inspection. It is worth checking the condition of the soundproofing regularly, especially in areas exposed to moisture, such as the area around the wheel arches.

Pay attention to any material that may have come loose, especially at the edges. If there are any problems, you can press down or replace the pieces of material.

When washing the interior of the car, it is better to avoid soaking the carpet too much to prevent moisture from getting into the soundproofing layers. If installed and maintained correctly, the soundproofing will retain its properties for many years.

Summary

Effective soundproofing of the car floor significantly improves acoustic comfort while driving. The process requires careful surface preparation, the use of appropriate materials and precise installation. The butyl mats ABM Professional and Xtreme form the first soundproofing layer, dampening vibrations and low-frequency noise. The second layer, ABM self-adhesive rubber foam, absorbs medium and high-frequency sounds.

Properly installed floor soundproofing has many advantages. Noise reduction improves the driver’s concentration and increases driving comfort. Better thermal insulation protects the cabin from the effects of temperature, and the additional layer of materials protects the car body from corrosion.

Regular checks of the soundproofing are particularly important in areas exposed to moisture. With proper maintenance, the insulation will remain effective for a long time. Investing in professional soundproofing pays off through greater driving comfort, less fatigue on long journeys and better sound quality of the audio system. A quiet vehicle interior not only improves comfort but also road safety.