Acoustics in conference rooms is a key factor affecting the quality of communication during business meetings. Inadequate sound conditions can lead to concentration problems, participant fatigue, and reduced overall meeting effectiveness. Modern offices often feature open spaces and hard surfaces that cause unwanted sound reflections and reduce speech intelligibility.

Proper soundproofing of a conference room not only enhances work comfort but also increases team productivity. Acoustic studies show that people in rooms with good acoustics are more focused and less prone to stress. Acoustic solutions, such as sound-absorbing foam, allow for significant improvement in working conditions without the need for costly renovations.

Investing in appropriate acoustic materials brings long-term benefits to the entire organization. Employees can communicate more effectively during video conferences, presentations, or brainstorming sessions. This leads to higher quality decision-making and overall job satisfaction.

The Impact of Acoustics on Business Meeting Effectiveness

The acoustic quality of a room directly affects participants’ ability to concentrate during meetings. Poor sound conditions force the brain to work harder to process auditory information, leading to faster fatigue.

Problems with Concentration and Speech Intelligibility

The reverberation time in a typical conference room should not exceed 0.6 seconds for speech frequencies. Exceeding this value causes overlapping sounds and makes it difficult to understand spoken words. This issue becomes especially problematic during phone calls or video conferences, where transmission quality further deteriorates the situation.

Background noise in a conference room should be kept below 35 dB. Higher levels significantly reduce listening comfort and require speakers to raise their voices. This effect is intensified in rooms with hard surfaces where sound reflects off walls, ceilings, and floors.

Poor acoustics particularly hinder communication for individuals with hearing difficulties. Even slight deterioration in sound conditions can exclude some participants from active involvement in the meeting.

Impact on Team Productivity

Studies conducted in office environments show that improving acoustics can increase productivity by up to 20%. Employees in quieter rooms make fewer mistakes and are more creative when solving problems.

Stress related to communication difficulties negatively affects team atmosphere. People become more irritable and less willing to collaborate. Good acoustics eliminate these issues and promote building positive professional relationships.

Meeting effectiveness increases when all participants can freely exchange ideas. The absence of acoustic problems allows for dynamic discussions without the need to constantly repeat statements.

Common Acoustic Problems in Meeting Rooms and Ways to Solve Them

Most conference rooms face similar acoustic challenges resulting from modern design and finishing materials. Identifying specific problems is the first step toward effectively resolving them.

Echo and Reverberation in the Room

Echo occurs when sound reflects off parallel walls and returns to the listener with a delay exceeding 50 milliseconds. This issue is especially noticeable in rectangular rooms with smooth walls. The solution is to use absorbing materials on opposite walls or to alter the room’s shape by adding elements that break up regular reflections.

Reverberation differs from echo in that it consists of many overlapping reflections creating a continuous noise. A long reverberation time causes successive words to overlap, making speech difficult to understand. Acoustic materials with a high sound absorption coefficient effectively shorten reverberation time.

The most problematic rooms are those with a volume exceeding 200 cubic meters and hard surfaces. Such rooms require a comprehensive approach to acoustic correction using various types of absorbing materials.

External Noise Penetration

Noise from corridors, elevators, or air conditioning significantly reduces comfort in conference rooms. The acoustic tightness of doors plays a key role in isolating external noise sources. Standard office doors often do not provide sufficient insulation.

Ventilation systems can generate noise exceeding permissible limits. The solution is to use acoustic silencers in ventilation ducts and properly position air intake and exhaust grilles.

Vibrations transmitted through the building structure also affect acoustic comfort. Rooms located near elevators, machinery, or busy streets are particularly problematic.

Main sources of external noise:

- Street traffic and public transportation

- Air conditioning and ventilation systems

- Conversations in corridors

- Sounds from adjacent rooms

- Vibrations from technical equipment

Effective acoustic insulation requires a comprehensive approach that considers all potential noise transmission paths. Often, it is necessary to apply several different solutions simultaneously.

How to Choose the Appropriate Thickness and Type of Acoustic Foam for Different Sizes of Conference Rooms

The selection of acoustic materials depends on many factors, including the room’s volume, its intended use, and the investment budget. Different types of acoustic foams have varying sound absorption properties across different frequency bands.

Technical Parameters of Absorbing Foams

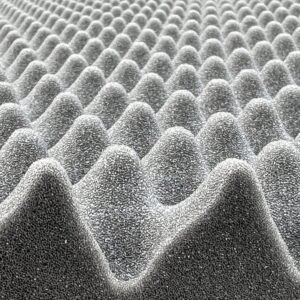

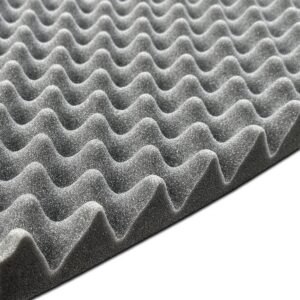

The sound absorption coefficient αw indicates the material’s effectiveness in reducing acoustic reflections. Values above 0.8 indicate very good absorbing properties. Foams with a thickness of 30 mm achieve αw around 0.6–0.7, while 50 mm materials can exceed 0.9.

The fire reaction class is a key safety parameter. Materials classified as B-s1,d0 are flame-retardant and do not emit toxic gases during a fire. All materials used in public buildings must comply with appropriate fire safety standards.

The density of the foam affects its durability and acoustic properties. Materials with a density of 25-30 kg/m³ provide an optimal balance of effectiveness to cost. Higher density improves low-frequency absorption but increases the product price.

Selecting Thickness Based on Room Volume

Conference rooms up to 20 m² require foam with a minimum thickness of 25 mm. Thinner foam may be insufficient for effective acoustic correction. Materials thinner than 20 mm mainly affect high frequencies, leaving the issue of speech-range reverberation unresolved.

Medium-sized rooms (20-50 m²) work best with foam thicknesses of 30-40 mm. This thickness ensures even absorption across a wide frequency range. Combining different thicknesses on various walls can further improve acoustic characteristics.

Large conference rooms over 50 m² require materials with a minimum thickness of 50 mm. Larger volume means longer reverberation time and the need for more effective solutions. It is often necessary to cover 40-60% of the wall surfaces with acoustic materials.

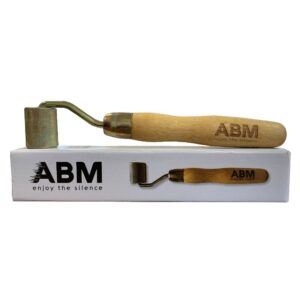

Insulation ABM offers a wide range of acoustic foams tailored to various applications. The company specializes in providing acoustic solutions for commercial and office buildings. The products available are characterized by high-quality craftsmanship and safety certifications.

Absorptive acoustic foams offered by Insulation ABM include materials of various thicknesses and properties. Each product is thoroughly described in terms of technical parameters and applications. Customers can choose from different colors and textures to match interior decor.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

Installation accessories are also an essential part of the acoustic system. Appropriate adhesives, tapes, and mounting elements ensure installation durability and user safety. All products offered are currently in stock.

Accessories in the ABM Insulation store

Tip: Before purchasing acoustic foam, accurately measure the wall surfaces and calculate the required amount of material with a 10% allowance for cutting waste.

Optimal Placement of Sound-Absorbing Materials in Conference Spaces

The effectiveness of an acoustic system depends not only on the quality of the materials but also on their proper placement within the room. Strategic positioning of absorbing foams can significantly improve acoustic comfort while using less material.

Priority for Sound Reflection Points

The walls behind the speaker require special attention because they reflect sound directly toward the listeners. Covering this surface with absorbing material eliminates unwanted echo and improves speech intelligibility. The mounting height should correspond to the head level of a standing person.

Ceilings in conference rooms often represent the largest sound-reflecting surface. Using acoustic panels or foam on the ceiling effectively reduces reverberation. It is especially important to cover the area above the conference table, where most conversations take place.

Room corners are places where low frequencies accumulate. Special bass absorbers or thicker foam in the corners help control these problematic frequencies. Often, covering the corners to a height of 1.5–2 meters is sufficient.

Principles of Symmetry and Acoustic Balance

Asymmetrical placement of acoustic materials can lead to an uneven sound field. Better results are achieved by applying symmetrical distribution of foam on opposite walls. This approach ensures equal acoustic conditions for all meeting participants.

Alternating placement of absorbing and reflecting surfaces creates a more natural acoustic environment. Completely soundproofing a room can make it sound “dead” and unpleasant. The optimal ratio is 50–70% of the wall surface covered with absorbing material.

The mounting height of the foam should consider typical positions of meeting participants. Materials placed too high or too low may be less effective. The optimal height is 0.8–2.5 meters from the floor.

Priority zones for installing acoustic materials:

- The wall behind the presentation area

- The ceiling above the conference table

- Side walls at the participants’ head height

- Room corners (bass absorbers)

- Areas around audio-video equipment

The placement of foam should also take into account the room’s aesthetics and not interfere with other furnishings. A well-designed acoustic system can serve as a decorative element of the interior.

Tip: Start by covering 30% of the wall surface with absorbing material, then gradually add more elements, testing the acoustics after each change.

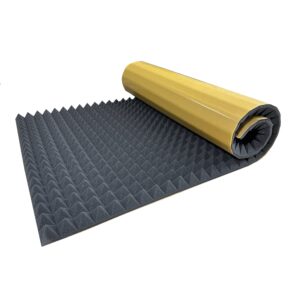

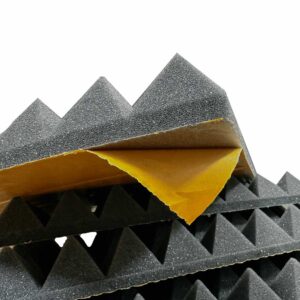

Step-by-Step Installation of Self-Adhesive Acoustic Panels

Proper installation of acoustic foam determines its effectiveness and durability. Self-adhesive panels are the simplest solution but require proper surface preparation and precise execution.

Surface Preparation for Installation

The wall surface must be clean, dry, and free of dust. Residues of paint, wallpaper, or other coatings can affect the adhesive’s grip. Surfaces painted with silicone or low-adhesion acrylic paints are particularly problematic.

The room temperature during installation should be between 18-25°C. Lower temperatures may impair the adhesive properties, while higher temperatures can make precise panel positioning difficult. Relative humidity should not exceed 60%.

Wall irregularities greater than 2 mm per meter can cause adhesion problems. Before installation, it is advisable to check the surface flatness with a straightedge and, if necessary, level it with putty. Gaps and voids also need to be filled.

Panel Adhesion Technique

Marking the position of each panel with a pencil facilitates precise installation. Starting from the center of the wall and arranging panels symmetrically ensures a better visual effect. The gaps between panels should be minimal but they must not overlap.

The protective film on the adhesive should be removed immediately before installation. The adhesive loses its properties after a few minutes of exposure to air. Pressing the panel should be even, from the center toward the edges, to avoid air bubbles.

The adhesive curing time is approximately 24 hours. During this period, panels should not be subjected to vibrations or impacts. The adhesive reaches full strength 72 hours after installation.

Order of Acoustic Panel Installation:

- Cleaning and preparing the surface

- Marking panel positions on the wall

- Checking room temperature and humidity

- Removing the protective film from the adhesive

- Precise positioning and pressing of the panel

- Checking adhesion after 24 hours

Installation in hard-to-reach areas may require the use of ladders or scaffolding. Work safety should be a priority, especially when installing on the ceiling.

Tip: Before installing all panels, apply one test panel and check its adhesion after 24 hours—this will help avoid problems with the entire installation.

Common Mistakes During Acoustic Foam Installation in Meeting Rooms

Incorrect installation can significantly reduce the effectiveness of the acoustic system and lead to premature material damage. Knowing common issues helps avoid them and achieve better results.

Surface Preparation Errors

Installing on damp walls is the most common cause of panel detachment. Moisture may come from leaks in the plumbing, condensation, or insufficient drying of fresh plaster. Before installation, wall moisture should be checked with a moisture meter.

Leaving dust and dirt on the installation surface significantly reduces adhesive bonding. Even a thin layer of dust can act as a barrier to proper adhesion. Cleaning the wall with a damp cloth and allowing it to dry provides better installation conditions.

Installing on unstable substrates, such as loose wallpaper or peeling paint, leads to problems. Such surfaces require removal of old coatings and priming before installing acoustic panels.

Problems with Layout and Orientation

Chaotic panel placement not only looks unprofessional but can also reduce acoustic effectiveness. Lack of symmetry causes uneven sound fields. Planning the layout on paper before starting installation helps avoid this problem.

Incorrect orientation of panels with directional structure can affect their acoustic properties. Some foams have different absorption characteristics depending on the fiber direction. The manufacturer’s instructions always specify the correct installation orientation.

Leaving gaps that are too large between panels reduces the system’s effectiveness. Gaps larger than 5 mm can create paths for sound reflections. Precise fitting of panels to each other ensures better acoustic results.

Common installation errors and their consequences:

| Error | Consequences | Solution |

|---|---|---|

| Installation on a damp wall | Panel detachment, mold | Check moisture, dry surface |

| Dirty surface | Poor adhesion | Thorough cleaning before installation |

| Uneven pressing | Air bubbles, poor adhesion | Press from the center toward the edges |

| Too large gaps | Reduced acoustic effectiveness | Precise panel fitting |

Installation temperature outside the recommended range can cause adhesive problems. Too low a temperature slows down glue curing, while too high a temperature can lead to premature hardening before proper panel positioning.

Tip: Always read the manufacturer’s installation instructions before starting work—each type of foam may have specific installation requirements.

Combining acoustic foams with other decor elements for better acoustics

A comprehensive approach to room acoustics includes not only specialized materials but also thoughtful use of furniture and decor elements. This solution allows for better results while maintaining interior aesthetics.

Furniture as acoustic elements

Upholstered chairs and armchairs serve as natural sound absorbers, especially effective in mid and high frequencies. Densely arranged chairs can absorb a significant portion of acoustic energy. The choice of upholstery is important—materials with an open structure are more effective than smooth leathers.

Bookcases and shelves filled with books create an irregular surface that scatters sound reflections. Different book thicknesses cause sound waves to reflect at various angles, reducing echo. Strategic placement of shelves can significantly improve room acoustics.

Curtains and draperies, especially those made of thick fabrics, effectively absorb high frequencies. Fabric folds increase the absorbing surface area. Curtains can be used as movable elements, allowing acoustic adjustment for different types of meetings.

Plants and natural elements

Large potted plants not only improve air quality but also affect room acoustics. Leaves and branches scatter sound waves, and the soil in pots absorbs low frequencies. Plants with large, soft leaves are particularly effective.

Green walls represent an advanced solution combining aesthetic and acoustic functions. The layer of vegetation on a special structure can achieve an absorption coefficient comparable to professional acoustic materials. Additionally, they improve the room’s microclimate.

Elements made of natural wood, such as panels or beams, can influence the acoustic characteristics of the room. Wood with an open structure absorbs some of the sound energy, while smooth surfaces reflect it. A combination of different wooden materials allows for acoustic tuning.

Equipment elements affecting acoustics:

- Upholstered furniture (chairs, sofas, poufs)

- Carpets and carpet coverings

- Curtains and fabric blinds

- Pictures in frames with matte glass

- Large-leaf potted plants

- Wooden panels with various textures

The combination of different elements allows for creating a balanced acoustic environment. Too many absorbing materials can make the room sound “dead,” while their absence causes excessive reverberation.

Tip: Use existing furniture elements as part of the acoustic system—significant improvement can often be achieved without additional costs.

Assessment of soundproofing effectiveness after applying absorbing foams

An objective evaluation of the effects of applied acoustic solutions allows verification of the investment’s effectiveness and possible system optimization. There are several assessment methods, ranging from simple listening tests to professional acoustic measurements.

Methods for measuring reverberation time

The RT60 reverberation time is a fundamental parameter characterizing room acoustics. The measurement involves generating a short sound signal and measuring the time it takes for the sound level to drop by 60 dB. Professional acoustic meters automatically calculate this parameter for different frequencies.

Mobile applications for acoustic measurement can serve as orientation tools, although their accuracy is limited. Measurements should be taken at several points in the room to obtain a representative picture of the acoustic conditions. Measurements in locations where meeting participants usually stay are particularly important.

Comparing measurements before and after installing acoustic materials shows the actual effectiveness of the applied solutions. A reduction in reverberation time by 30-50% indicates a significant improvement in acoustic conditions. Values below 0.6 seconds are optimal for conference rooms.

Practical tests and subjective evaluation

The speech intelligibility test involves reading standard word lists from different positions in the room. Listeners assess the percentage of correctly understood words. An improvement of 20-30% after applying acoustic materials indicates their effectiveness.

Evaluating acoustic comfort by room users is an equally important success indicator. Surveys conducted before and after acoustic modernization show the real impact of changes on work comfort. Questions should address ease of concentration, fatigue after meetings, and overall satisfaction with working conditions.

Test recordings made under identical conditions before and after installing foam panels allow for an objective comparison of sound quality. Recordings of phone calls or video conferences are especially useful, as they demonstrate a real improvement in communication.

Parameters for evaluating soundproofing effectiveness:

| Parameter | Value before | Value after | Improvement |

|---|---|---|---|

| Reverberation time RT60 | 1.2-1.8 s | 0.4-0.6 s | 60-70% |

| Background noise level | 40-50 dB | 30-35 dB | 20-30% |

| Speech intelligibility | 60-70% | 85-95% | 25-35% |

| Acoustic comfort | 3/10 | 8/10 | 150% |

Regular inspections of acoustic materials help maintain their effectiveness. Dust and dirt can reduce the absorbing properties of foam panels. Vacuuming or cleaning every 6-12 months extends the lifespan of the installation.

Tip: Make a test recording before installing the foam panels and compare it with a recording after the work is completed—the difference will be clearly audible and confirm the effectiveness of the investment.

Summary

Proper acoustics in a conference room represent an investment in the efficiency and comfort of the entire team’s work. Using appropriate sound-absorbing materials can significantly improve communication conditions and increase meeting productivity. The key to success is a thoughtful approach that considers the room’s specifics, its purpose, and the investment budget.

Installing acoustic foam panels does not require specialized skills, but precise execution determines the durability and effectiveness of the solution. Avoiding common installation mistakes and using proven techniques guarantees achieving the desired results. Combining acoustic materials with a well-planned interior design allows for creating a functional and aesthetically pleasing workspace.

Regular evaluation of the effectiveness of implemented solutions enables their optimization and maintains high acoustic quality over time. Investing in improving conference room acoustics pays off through increased team efficiency and better quality of business decisions.