Rubber Foam. Acoustic Insulation Self-adhesive ABM, 32mm, 1m2

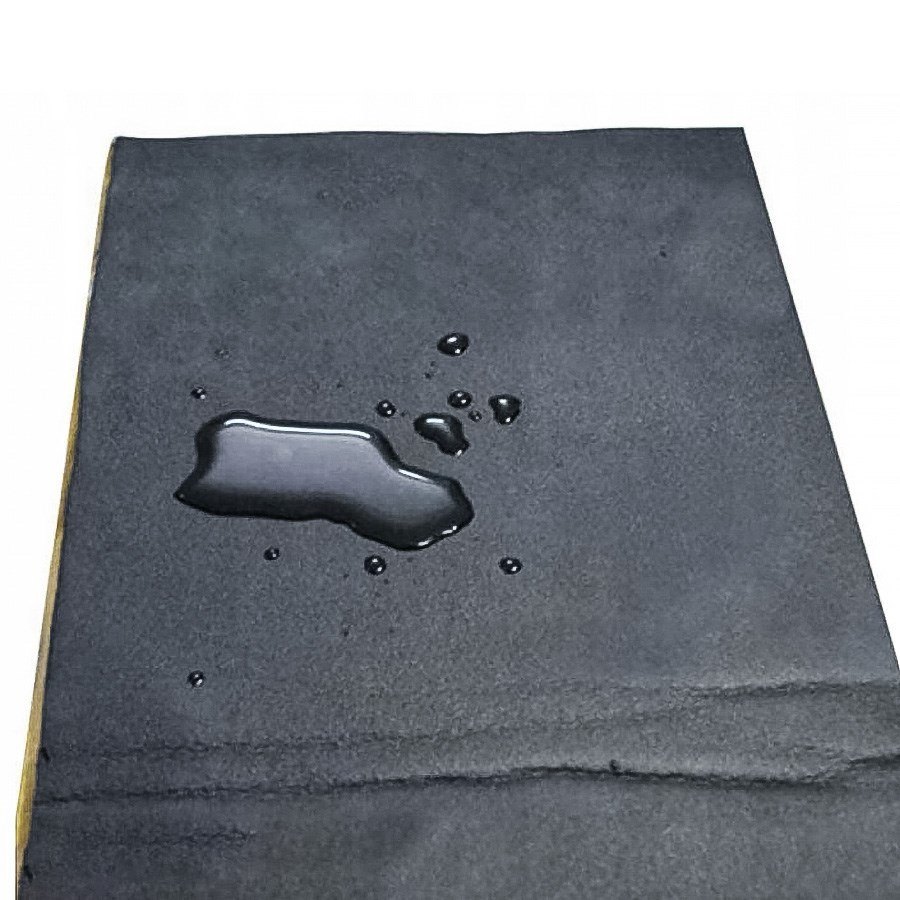

The material does not absorb moisture and is resistant to chemicals, creates an acoustic barrier and perfectly absorbs noise and insulates from temperature (thermally).

We use paper or foil as a carrier.

This material effectively eliminates most household noises of medium intensity: a crying baby, barking dogs, loud conversations, the sounds of the TV or other household appliances.

It is used in the process of reconstruction or construction of new buildings as an additional sound-absorbing material for load-bearing structures or internal partitions. Such structural elements may be: ceiling slabs, brick or concrete walls, plasterboard structures and their elements.

Our ABM acoustic mats are characterized by:

- Do not absorb water, odors or chemicals;

- They have low weight and very strong glue;

- They are flexible, therefore very easy to install;

- Isolate mids and absorb high frequencies;

- They have high density;

- They do not oxidize, do not emit substances harmful to health, and are not toxic;

- They are self-extinguishing and do not spread fire;

- Can be used as soundproofing mats on walls;

- Good acoustic insulation.

Technical data:

- Density: 50-60 kg/m3;

- Closed cellular structure;

- Water absorption: maximum 0.1%;

- Temperature range: -50°C to 110°C according to EN 14706;

- Reaction to fire: Self-extinguishing, does not create burning drops, does not spread fire according to EN 13501-1 (D-s3, d0);

- Thermal conductivity: λ ≤ 0.036 according to EN ISO 13787;

- Water penetration: µ ≥ 7000 according to EN 12086 and EN 13469;

- pH: Neutral;

- Compliant with CE 0551-FEF standards;

- Compliant with the harmonized European construction product standard PN-EN 14304:2009;

- Health aspects: Does not contain dust or fibers, does not contain heavy metals.

OUR PRODUCTS HAVE HYGIENE CERTIFICATE NO. 335/322/340/2020 OF SEPTEMBER 30, 2020

Soundproofing rubber foam can be easily used as:

- Automotive: soundproofing of cars, campers, yachts and other vehicles, car audio;

- Construction: ventilation (air ducts), air conditioning, refrigeration, heating, buildings (walls, floors, doors, ceilings);

- Industry: soundproofing of machines, compressors, generators

Why ABM?

1. Rubber foam acoustic mats are made only from primary, natural materials, which means that we do not add waste to our materials.

2. As a manufacturer, we guarantee the highest quality.

3. As a manufacturer, we provide a 2-year warranty for our rubber mats.

4. Thanks to our many years of experience, we enjoy high quality and customer satisfaction all over the world.Our products are sold in most European Union countries, the United States and Australia. Our ABM mats have soundproofed over 40,000 vehicles around the world!

5. When you buy directly from the manufacturer, you get lower prices, high quality, you know what product you are getting, and you can be sure that no harmful waste is added in the production process.

Installation of the ABM rubber mat

1. Degrease and clean the soundproofed surface well.It must be clean and dry.

2. Peel off the protective layer of paper or foil.

3. Apply the ABM rubber mat.

Sample quantity for car soundproofing.

Examples of quantities of butyl mats and rubber foams needed to soundproof a car*:

- Front doors (pair): approximately 2 m2 of butyl mat + 1 m2 of rubber foam;

- Rear doors (pair): approximately 1.5 m2 of butyl + 1 m2 of rubber foam;

- Trunk with wheel arches: approximately 3 m2 of butyl mat + 3 m2 of rubber foam;

- Floor with engine compartment: approximately 3.5 m2 of butyl mat + 3.5 m2 of rubber foam pieces;

- Roof: approximately 2 m2 of butyl mat + 2 m2 of rubber foam.

*(quantities may be larger or smaller depending on the model/type of car/vehicle)

To obtain the best – full acoustic insulation, we recommend using foam mats together with sound-absorbing butyl mats available in our store.