Set of materials for soundproofing room doors, 2×2m2, White

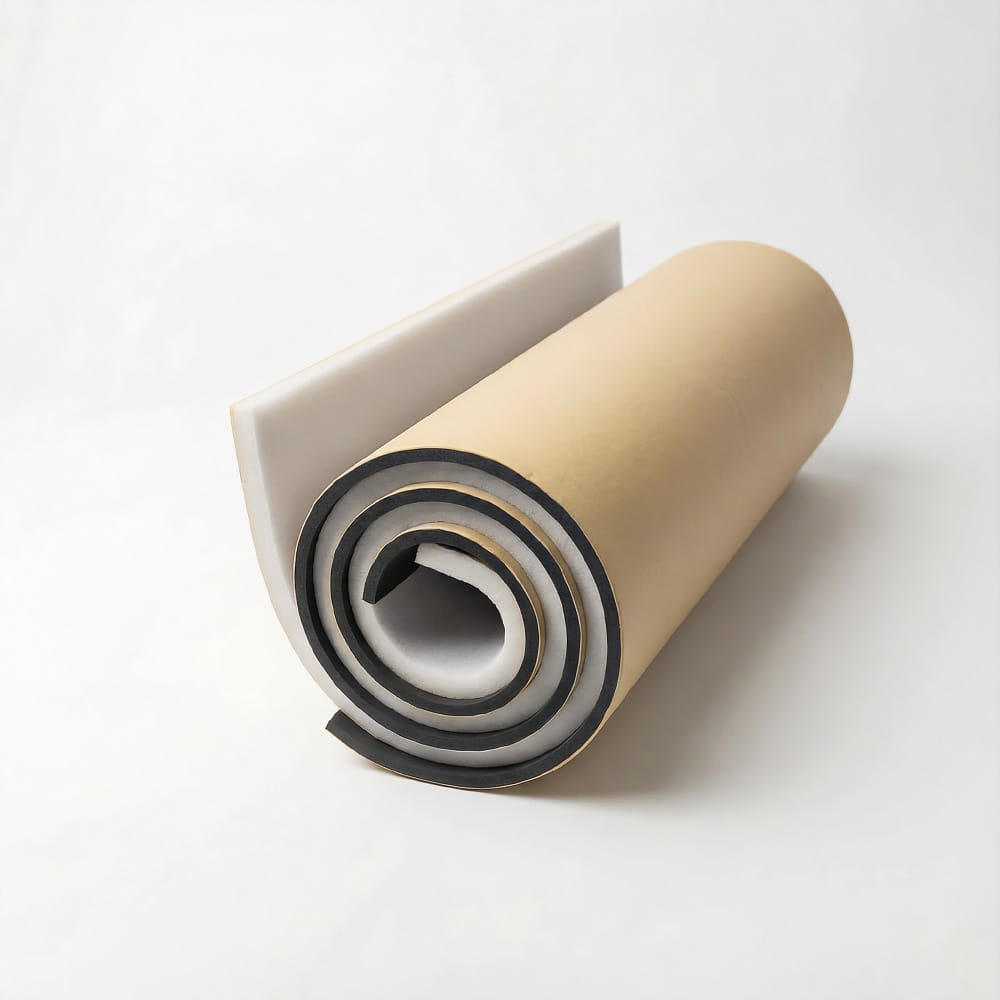

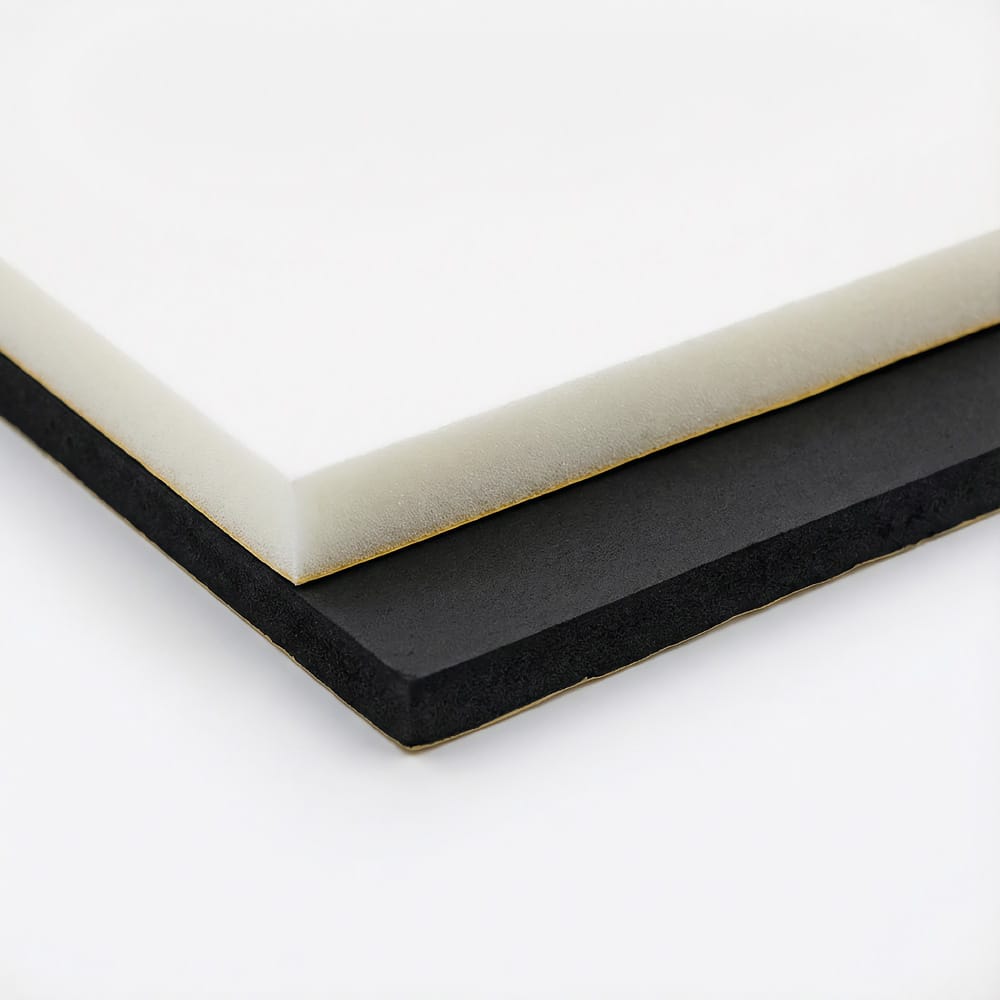

Effective soundproofing of interior doors requires the use of materials with the highest insulation quality. The two-layer insulation system combines black 10 mm rubber foam and white 20 mm polyurethane foam. Each layer serves a specific acoustic and thermal function. A total area of 4 m² is sufficient for comprehensive protection of standard interior doors. The black rubber foam forms the first protective layer against heat loss. The material has a density of 50-60 kg/m³ and a thickness of 10 mm. The closed-cell structure prevents moisture and odor penetration.

The white PUR foam constitutes the second layer of the sound absorption system. Its 20 mm thickness ensures effective reduction of sound waves across various frequencies. The material, with a density of 25 kg/m³, is characterized by lightness and flexibility. The self-adhesive layers of both foams eliminate the need for additional adhesives. Installation can be done independently without specialized tools. The white surface of the top layer facilitates cleanliness and aesthetics.

The manufacturer ABM Insulation guarantees that the materials comply with European construction standards. The CE 0551-FEF certificates and the PN-EN 14304:2009 standard confirm the high quality of the products. Both materials have self-extinguishing properties according to EN 13501-1 standards. The neutral pH ensures health safety during use. The 2-year warranty covers the full range of insulation functionalities. The materials contain no heavy metals or toxic substances.

Technical data

Technical specification of the set includes detailed parameters of both insulation layers. Each material has been certified in accordance with the requirements of European construction standards. Rubber foam meets the requirements of the EN 14706 standard regarding thermal resistance. Polyurethane foam is characterized by mechanical parameters specified by the manufacturer. The table below presents complete technical data for both materials comprising the insulation set.

| Parameter | Rubber foam 10 mm | PUR foam 20 mm |

|---|---|---|

| Thickness | 10 mm | 20 mm |

| Sheet dimensions | 100 cm × 200 cm | 100 cm × 200 cm |

| Area | 2 m² | 2 m² |

| Weight | 1.1 kg | 0.8 kg |

| Density | 50-60 kg/m³ | 25 kg/m³ |

| Water absorption | maximum 0.1% | resistant surface |

| Temperature range | minus 50°C to 110°C | standard Range |

| Thermal conductivity | λ ≤ 0.036 W/mK | Standard |

| Vapor transmission | µ ≥ 7000 | High resistance |

| pH | Neutral | Neutral |

| Reaction to fire | D-s3, d0 (EN 13501-1) | ≤100 mm/min |

| Stiffness 40% | – | 3-3.8 kPa |

| Permanent deformation 50% | – | less than 6% |

| Tensile strength | – | minimum 90 kPa |

| Elongation at break | – | minimum 120% |

| Layer adhesive | self-adhesive | self-adhesive |

The total weight of the set is 1.9 kg for an area of 4 m². The lightness of the materials facilitates transport and installation without burdening the door structure. The closed-cell structure in the rubber foam provides an excellent barrier against water vapor. The thermal conductivity coefficient λ ≤ 0.036 W/mK classifies the material as a highly efficient insulator. The diffusion resistance µ ≥ 7000 prevents moisture penetration through the insulation layer.

The mechanical parameters of the PUR foam define its strength and flexibility. The stiffness at 40% compression is 3-3.8 kPa. Permanent deformation at 50% compression does not exceed 6%. Tensile strength of at least 90 kPa guarantees stability during use. The relative elongation at break exceeds 120%, indicating the material’s elasticity. Flame resistance does not exceed 100 mm/min according to conducted tests.

Soundproofing Kits

Complete insulation set consists of two different materials with complementary properties. The black rubber foam forms the base layer directly adhering to the door surface. The white polyurethane foam serves as the outer layer responsible for sound absorption. The combination of both materials creates an effective two-stage insulation system. Each layer is designed to perform a specific acoustic and thermal function. Self-adhesive layers allow for quick installation without the use of additional adhesives.

Self-adhesive rubber foam 10 mm, 2 m2

Flexible rubber foam forms the fundamental layer of the home door insulation system. The black color of the material results from the natural composition of high-quality rubber. 10 mm thickness provides an optimal balance between insulation efficiency and installation practicality. A sheet measuring 100 cm × 200 cm covers an area of 2 m². Density of 50-60 kg/m³ classifies the material as a high-performance thermal and acoustic insulator. Closed cells in the structure block water and water vapor penetration.

Main technical parameters of the rubber foam:

- Minimal water absorption up to 0.1% prevents moisture buildup inside the material

- Wide temperature range from minus 50°C to 110°C according to EN 14706 standard

- Low thermal conductivity λ ≤ 0.036 W/mK ensures effective thermal insulation

- High diffusion resistance µ ≥ 7000 according to EN 12086 and EN 13469 standards

- Self-extinguishing properties according to D-s3, d0 classification under EN 13501-1

- Chemical resistance to oils, fuels, and most solvents

The closed-cell structure in the rubber foam eliminates odor absorption. The material does not oxidize or degrade under weather conditions. The foam’s flexibility allows it to conform to uneven door surfaces. The adhesive layer covered with protective foil activates after removing the backing. The material’s durability exceeds 20 years while maintaining full insulating properties. The foam does not emit harmful substances and contains no dust or fibers.

Polyurethane white sound-absorbing foam 20 mm, 2 m2

White PUR foam features an open-cell structure ideal for absorbing sound waves. A thickness of 20 mm provides effective noise reduction across a wide frequency range. Density of 25 kg/m³ makes the material lightweight while maintaining high acoustic efficiency. The white surface covered with a protective foil facilitates cleaning and hygiene maintenance. Sheet dimensions of 100 cm × 200 cm correspond to standard residential door sizes. Weighing 0.8 kg, it does not burden the door structure or hinges.

Key features of polyurethane foam:

- Excellent sound absorption in the frequency range of 1000-4000 Hz achieves nearly 100% effectiveness

- Surface resistant to short-term exposure to water, oil, and fuel

- Easy processing the material can be cut with a regular wallpaper knife

- Neutral pH safe for health and does not cause allergies

- Self-extinguishing properties enhance fire safety of the installation

- Self-adhesive layer with protective foil facilitates precise installation

The polyurethane structure effectively disperses the energy of sound waves passing through the material. The sound absorption coefficient can reach values of 0.9-0.95 for specific frequencies. The foam reduces airborne noises such as conversations, music, or television sounds. The material’s flexibility allows installation on curved surfaces. Mechanical parameters guarantee shape retention throughout the entire service life. High moisture resistance enables use in rooms with elevated relative humidity.

The combination of both foams creates a system of complementary insulating layers with a total thickness of 30 mm. The black rubber foam blocks vibrations and heat flow through the door. The white polyurethane foam absorbs sound waves reaching the surface. Total noise reduction can reach 30-40 dB depending on the door construction. The two-layer system eliminates acoustic and thermal bridges. The self-adhesive layers provide a durable bond without the need for additional materials.

Application

Insulation material set is widely used in various types of residential and commercial buildings. Entrance doors to apartments require effective acoustic insulation from noise coming from stairwells. Thermal insulation of exterior doors reduces heat loss during the heating season. The materials perform equally well in single-family homes as well as multi-family buildings. The two-layer system provides comprehensive protection against external factors.

Application areas of the insulation set:

- Apartment entrance doors acoustic insulation from noise in corridors and stairwells

- Exterior house doors thermal protection reducing energy consumption for heating

- Interior doors acoustic separation between rooms requiring quiet

- Living room doors dampening sounds from TV, music, and conversations

- Bedroom doors ensuring peaceful sleep by reducing external noises

- Home office doors acoustic insulation of workspaces from family life

- Technical doors in commercial buildings requiring acoustic control

- Doors in buildings near busy streets protection against traffic noise

The insulation effectiveness of the set depends on the door construction and the tightness of the installation. The materials work best in combination with door seals that eliminate gaps. Noice reduction can reach up to 30-40 dB with proper application. The two-layer system simultaneously improves both thermal and acoustic properties of the doors. The use in exterior doors significantly reduces room heating costs. The insulation performs well in various climatic and temperature conditions.

Features and Benefits

The two-layer insulation system combines the advantages of both materials to create comprehensive protection for home doors. The black rubber foam blocks heat flow and mechanical vibrations. The white polyurethane foam absorbs sound waves across a wide frequency range. Closed cells in the rubber layer prevent moisture and water vapor penetration. The open structure of the PUR foam effectively disperses acoustic energy. Self-adhesive layers eliminate problems related to applying additional adhesives.

Materials certified according to European building standards guarantee safety and durability. The neutral pH of both foams ensures no chemical reactions with door materials. Self-extinguishing properties meet the strict fire safety requirements for residential buildings. The materials contain no heavy metals or toxic substances. The foam flexibility allows adaptation to various surfaces and door shapes. The light weight of the set does not require reinforcement of hinges or door frames.

Main advantages of the insulation set:

- Double thermal and acoustic insulation in one installation system

- Noise reduction by 30-40 dB with proper application

- Energy savings by reducing heat loss through doors

- Minimal water absorption, maximum 0.1% in the rubber layer

- Wide temperature range, from minus 50°C to 110°C, maintaining insulating properties

- Self-adhesive installation, no need for additional adhesives

- Durability exceeding 20 years, maintaining full performance parameters

- Chemical resistance to oils, fuels, and most solvents

- Health safety, free from toxic substances and dust

- Easy processing, cut with a standard wallpaper knife without specialized tools

The acoustic efficiency of polyurethane foam reaches nearly 100% at frequencies between 1000-4000 Hz. These are most troublesome for human hearing and come from typical household sources. The closed-cell structure in rubber foam eliminates odor absorption from stairwells. The white outer surface facilitates visual inspection of installation quality. The manufacturer’s warranty covers a full 2 years from the date of material purchase.

Our products have a hygiene certificate No. 335/322/340/2020 dated 09/30/2020

Installation instructions

Proper installation of the insulation set requires preparing the door surface and precise application of the layers. A clean and degreased surface ensures a durable bond of the self-adhesive layers. Installation temperature should be between 15-25°C for optimal adhesive activation. The door should be removed from the hinges or installation should be done with the door open. The order of layer application is crucial for the effectiveness of the insulation system.

Steps for installing the insulation set:

- Clean the door surface using extraction gasoline or isopropanol

- Dry the surface with a clean cloth and wait 10 minutes

- Remove the protective film from the self-adhesive black rubber foam layer

- Apply the rubber foam directly onto the door surface, pressing from the center outward

- Smooth the surface with a metal roller to eliminate air bubbles

- Remove the protective film from the self-adhesive white polyurethane foam layer

- Apply the PUR foam onto the previously installed rubber foam layer

- Press the layers together by hand or with a roller to ensure full adhesion of surfaces

The installation can be performed over the entire door surface or only in selected areas. Maximum insulation efficiency requires covering at least 80% of the door surface. Cutting materials to the required shape is done with a standard wallpaper knife. Excess material should be trimmed, leaving a 5 mm allowance on edges. The adhesive activation temperature is achieved by pressing layers together for at least 30 seconds. Full adhesive bond strength occurs 24 hours after installation.

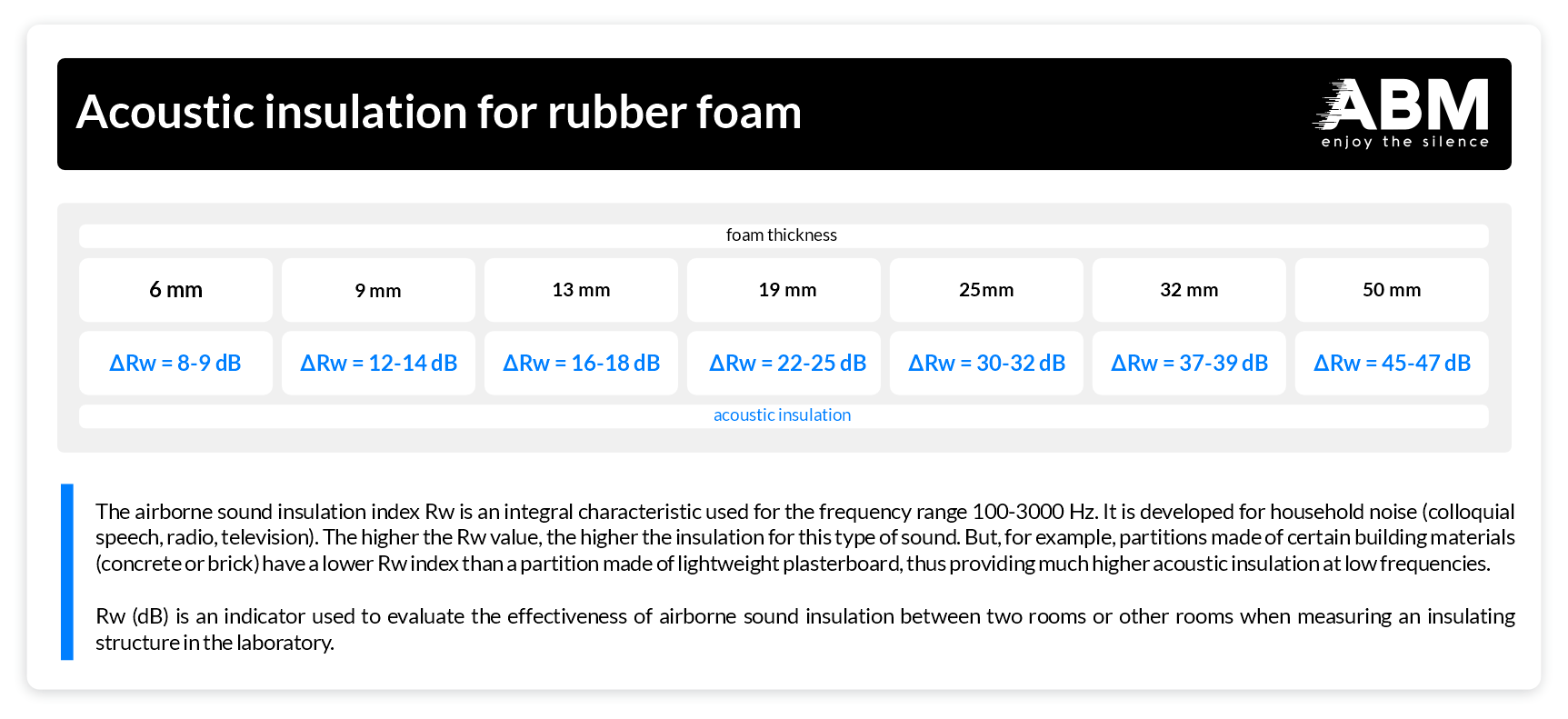

Acoustic insulation parameters

Sound absorption coefficient is a fundamental parameter for assessing the effectiveness of acoustic materials. Polyurethane foam achieves values of 0.9-0.95 for specific frequencies. This indicates almost complete absorption of sound energy passing through the material. The open-cell structure in PUR foam acts as a labyrinth that scatters acoustic waves. Rubber foam blocks mechanical vibrations transmitted through the door structure. The combination of both materials creates a barrier against airborne and structural sounds.

Noise reduction measured in decibels depends on the thickness and density of the materials used. A two-layer system with a total thickness of 30 mm can provide a reduction of 30-40 dB. This corresponds to halving the noise level perceived by the human ear. Mid frequencies between 1000-4000 Hz are most effectively dampened by polyurethane foam. This range includes human speech, music, and most household sounds. Low frequencies below 500 Hz require greater material thickness or additional layers.

Acoustic insulation also depends on installation tightness and eliminating gaps in the doors. Even small gaps can significantly reduce acoustic insulation effectiveness. Door seals around frames and thresholds eliminate sound transmission paths. The insulation system works most effectively when combined with full door sealing. A 10 mm thickness of rubber layer provides additional mass that increases insulation. The surface mass of the material directly affects its ability to block airborne sounds.

Thermal properties and energy savings

Thermal conductivity λ ≤ 0.036 W/mK classifies the rubber foam as a highly efficient thermal insulator. A value comparable to the best insulation materials used in construction. Closed cells in the rubber structure block air convection that transfers heat. PUR foam also contributes to thermal insulation through an additional air layer. Total thermal resistance of the two-layer system significantly exceeds that of the door material itself.

Heat loss through exterior doors can account for 10-15% of total energy loss in a building. Using thermal insulation reduces heat flow through the door surface. Energy savings on heating can reach 5-8% depending on the building design. The material pays off through lower heating bills within 3-5 years. Temperature range from minus 50°C to 110°C guarantees stability of properties under various conditions.

Diffusion resistance µ ≥ 7000 prevents water vapor from penetrating the insulation layer. It eliminates moisture condensation inside the door structure that leads to mold. Material flexibility ensures tight adhesion to the door surface without thermal gaps. The absence of thermal bridges maximizes thermal insulation efficiency. Durability of properties exceeds 20 years without degradation of parameters.

Safety and quality certificates

European standards CE 0551-FEF and PN-EN 14304:2009 confirm the compliance of materials with building requirements. Fire classification D-s3, d0 according to EN 13501-1 defines the material’s reaction to fire. The D rating indicates limited combustibility, s3 minimal smoke emission. The d0 symbol confirms no flaming droplets during material combustion. Self-extinguishing properties of both foams prevent the spread of fire.

Health safety confirms the absence of toxic substances in the material composition. The foams do not contain heavy metals, asbestos, or dust harmful to the respiratory system. Neutral pH eliminates the risk of allergic reactions or skin irritation. The materials do not emit volatile organic compounds during use. Mold resistance and bacteria ensure hygienic conditions throughout the entire usage period.

Manufacturer’s warranty ABM Insulation covers 2 years from the date of material purchase. The warranty covers maintaining insulating, mechanical, and adhesive properties. Quality certificates confirm tests conducted according to European procedures. The materials have undergone aging resistance and climatic condition tests. Durability exceeding 20 years while maintaining full technical parameters.