Acoustic insulation plays a key role in creating comfortable living, working, and entertainment spaces. One of the most important factors affecting the effectiveness of these materials is the thickness of acoustic foams. This parameter directly determines the range of frequencies that will be effectively absorbed as well as the overall efficiency of the insulation system.

Understanding the relationship between material thickness and its absorbing properties allows for optimal selection of solutions for specific needs. Professional acoustic foams, such as those offered by ABM Insulation, form the foundation of modern acoustic control systems. Their proper selection in terms of thickness can significantly improve room comfort.

Knowledge about the mechanisms of sound absorption by materials of varying thickness enables informed purchasing decisions. Investing in properly selected acoustic foams translates into long-term benefits related to acoustic comfort and energy efficiency of buildings.

Physical mechanisms of sound absorption by acoustic foams of different thicknesses

Sound absorption by acoustic foams is based on complex physical processes occurring within the porous structure of the material. Sound waves penetrating into the foam encounter numerous obstacles in the form of air cell walls. Acoustic energy is gradually converted into heat through friction between air molecules and the internal surfaces of the material.

The thickness of the foam directly affects the intensity of this process and the range of frequencies that can be effectively absorbed. Thicker materials offer a longer path for penetrating sound waves, increasing the likelihood of their absorption. This process is particularly effective for lower frequencies, which are characterized by longer wavelengths.

The principle of air cells in foam structure

The cellular structure of acoustic foams is a key element in sound absorption systems. Each air cell acts as a miniature resonator where air molecules perform oscillatory movements under the influence of sound waves. The cell walls provide contact surfaces where sound energy dispersion occurs.

Thicker foams contain a greater number of layers of air cells, which translates into an increased active surface area. This structure allows multiple reflections of sound waves within the material, increasing their chances of being absorbed. The optimal size and spatial distribution of cells determine absorption efficiency across different frequency ranges.

Dispersion of acoustic energy in porous material

Acoustic energy disperses through a series of physical mechanisms present in the porous structure of foam. The main process is viscous friction occurring between oscillating air molecules and cell walls. Additionally, thermoelastic damping related to compression and expansion of air in enclosed spaces occurs.

The material thickness affects the intensity of these processes by increasing the number of interactions between sound waves and the foam structure. Thicker materials provide a longer contact time, leading to more effective conversion of acoustic energy into heat. This process is especially efficient for frequencies corresponding to the characteristic dimensions of the cellular structure.

The impact of acoustic impedance on absorption efficiency

The acoustic impedance of a material is a measure of the resistance it offers to a sound wave passing through it. This parameter depends on the material’s density, sound propagation speed, and porous structure characteristics. Thicker foams have higher acoustic impedance, which affects their absorption properties across different frequency ranges.

Optimal acoustic impedance should be matched to the spectral characteristics of the absorbed sounds. Materials with lower impedance better absorb high frequencies, while higher impedance favors absorption of lower frequencies. Foam thickness allows control over this parameter, enabling adjustment of material properties for specific applications.

Tip: When selecting foam thickness, consider the dominant frequencies in the room and match the material’s acoustic impedance to the acoustic specifics of the space.

Frequency characteristics of foams with different thicknesses

The relationship between acoustic foam thickness and its frequency characteristics is a fundamental principle in designing acoustic insulation systems. Thin materials are particularly effective at absorbing high frequencies, while thicker foams effectively absorb a broader range of the sound spectrum, including low frequencies.

This mechanism results from the physical properties of sound wave propagation in porous structures. High frequencies have short wavelengths that easily penetrate surface layers of the material. Low frequencies require deeper penetration into the foam structure, which is only possible with materials of adequate thickness.

Thin foams and their effectiveness against high frequencies

Acoustic foams with a thickness of 10-25 mm show the highest efficiency in frequency ranges above 1000 Hz. The surface structure of these materials perfectly matches the short wavelength of high frequencies, providing effective absorption of acoustic energy. The absorption process mainly occurs in the outer layers of the material.

The frequency characteristics of thin foams include:

- Frequencies 2000-8000 Hz – maximum absorption efficiency

- Range 1000-2000 Hz – good absorption efficiency

- Below 500 Hz – limited effectiveness

The use of thin foams is especially justified in rooms where high-frequency sounds dominate, such as recording studios or vocal booths.

Thick Materials and Low-Frequency Absorption

Acoustic foams thicker than 50 mm are characterized by their ability to effectively absorb low frequencies in the 125-500 Hz range. A larger volume of material allows penetration of long sound waves and their gradual absorption in the deeper layers of the porous structure.

The effectiveness of low-frequency absorption by thick foams results from:

- Increased propagation path of sound waves inside the material

- A greater number of interactions between waves and the cellular structure

- Higher heat capacity of the material enabling energy conversion

Thick foams form the basis of acoustic control systems in rooms with low-frequency resonance issues.

Optimal Thickness for Full Sound Spectrum

Analysis of frequency characteristics for various thicknesses of acoustic foams indicates optimal ranges for balanced absorption across the sound spectrum. Materials with a thickness of 25-40 mm represent a compromise between effective high-frequency absorption and the ability to absorb mid frequencies.

| Foam Thickness | Absorption Efficiency | Frequency Range | Application |

|---|---|---|---|

| 10-15 mm | High for HF | 2000-8000 Hz | Vocal booths |

| 25-30 mm | Medium for MF/HF | 500-4000 Hz | Home studios |

| 40-50 mm | Good for LF/MF | 125-2000 Hz | Cinema rooms |

| 75-100 mm | High for LF | 63-1000 Hz | Bass traps |

The optimal thickness depends on the acoustic characteristics of the room and the dominant frequencies requiring control.

Noise Reduction Coefficient Depending on Thickness

The Noise Reduction Coefficient (NRC) is a standardized measure of a material’s acoustic absorption effectiveness in the frequency range of 250-2000 Hz. The NRC value increases with foam thickness, reaching a maximum for materials with a thickness of 75-100 mm.

The relationship between NRC and thickness is characterized by:

- Linear increase for thicknesses of 10-40 mm

- Slowing growth above 50 mm thickness

- Plateau for materials thicker than 75 mm

The practical use of the NRC allows comparison of the efficiency of different foam thicknesses and optimization of acoustic solutions in terms of cost.

Tip: For rooms requiring control over the full frequency spectrum, it is recommended to use a combination of foams with different thicknesses or to choose materials with a thickness of 30-40 mm as an optimal compromise.

Material Density and Thickness in the Context of Acoustic Performance

The interaction between material density and its thickness determines the final acoustic efficiency of absorbing foams. Density affects the porous structure of the material, airflow resistance, and mechanical characteristics, which combined with thickness define spectral absorption properties.

Materials with different densities exhibit different acoustic behavior at the same thickness. Lower-density foams have greater porosity and lower airflow resistance, which favors absorption of high frequencies. Higher density increases airflow resistance, which can improve absorption of mid frequencies but may limit penetration of high frequencies into the material’s interior.

Optimizing the balance between density and thickness requires consideration of the target room’s acoustic specifics. Different combinations of these parameters allow tuning absorption properties to specific application requirements.

The Relationship Between Density and Airflow Resistance

Airflow resistance is a key parameter determining the acoustic properties of porous materials. This resistance increases with material density and decreases as pore diameter in the foam structure increases. Material thickness further modifies this parameter by lengthening the airflow path.

The relationships between parameters are characterized by the following dependencies:

- Low density + large thickness – optimal for high frequencies

- Medium density + medium thickness – universal application

- High density + small thickness – effective for mid frequencies

- High density + large thickness – may shift absorption toward lower frequencies

Measuring airflow resistance enables prediction of material acoustic properties and optimization of its physical parameters.

Optimization of Parameters for Various Applications

Selecting the optimal combination of density and thickness of acoustic foam requires analyzing the specifics of each application. Different types of rooms have distinct acoustic requirements that determine the choice of appropriate material parameters.

Optimization criteria include:

- Frequency spectrum of dominant sounds

- Available space for material installation

- Aesthetic and functional requirements

- Budgetary constraints of the project

- Environmental conditions prevailing in the room

Professional acoustic foams from ABM Insulation offer a wide range of density and thickness combinations, allowing customization of properties to meet the individual needs of each project.

Trade-off Between Material Mass and Absorption Effectiveness

Increasing the thickness of acoustic foam leads to an increase in its mass, which can create additional installation and economic challenges. Heavier materials require reinforced mounting systems and may increase structural loads on the building. Optimizing this trade-off requires balancing acoustic benefits with practical limitations.

The analysis of material mass efficiency considers:

- Absorption coefficient per unit mass of the material

- Installation cost as a function of foam mass

- Structural requirements for mounting systems

- Long-term durability of the material

Modern acoustic foams feature optimized structures that maximize absorption efficiency while minimizing material mass.

Tip: When selecting acoustic foam, conduct a total cost analysis that considers not only the price of the material but also installation costs and long-term acoustic benefits.

Foams, Acoustic Panels Absorbing Sound at ABM Insulation Store

Effective acoustic control in rooms is fundamental to comfortable functioning in the modern world. Ambient noise negatively affects concentration, productivity, and overall well-being of users in residential and commercial spaces. Professional acoustic solutions enable elimination of unwanted sounds and improve interior acoustic quality.

ABM Insulation Store offers a comprehensive range of sound-absorbing acoustic foams characterized by high sound absorption effectiveness. The products available include materials with various thicknesses, from 2.5 EUR (10 mm) up to 12.5 EUR (50 mm), and diverse surface shapes. Each product is designed for maximum efficiency in absorbing sound waves across a wide frequency spectrum.

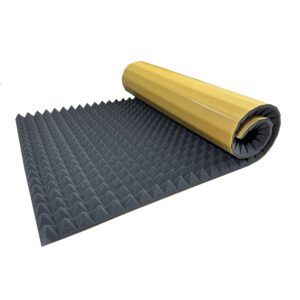

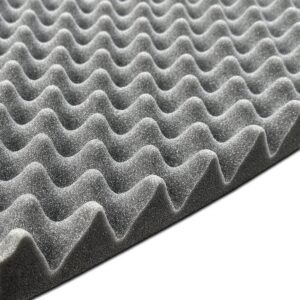

Technical Characteristics

ABM Insulation acoustic absorbing foams are made from high-quality polyurethane materials with an open-cell structure. This structure ensures optimal absorption of acoustic energy by converting sound waves into heat. The materials feature various surface profiles, including classic flat panels and profiled shapes such as pyramids.

Main technical parameters include:

- Thickness from 10 mm to 50 mm depending on the model

- Open-cell structure providing high porosity

- Flat surfaces and profiled types like WAVE and PYRAMIDS

- Available in self-adhesive versions and without adhesive

- Resistance to environmental factors and operational durability

The products are available in various sheet formats, allowing customization to the individual installation needs of each project.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

Professional and Home Applications

The wide range of applications for acoustic foams includes both professional recording studios and home spaces requiring improved acoustic comfort. Music studios use these materials to control reverberation and eliminate unwanted sound reflections. Conference rooms and offices apply foams to improve speech intelligibility and reduce background noise.

Application areas include:

- Recording studios and vocal booths requiring precise acoustic control

- Home theaters and audiovisual rooms for optimal sound reproduction

- Offices and commercial spaces to enhance work comfort

- Apartments and single-family homes to eliminate ambient noise

- Industrial spaces requiring noise emission reduction

The variety of available thicknesses and surface shapes allows adaptation of the solution to the specifics of each room and its acoustic requirements.

Installation Process and Maintenance

The installation of acoustic absorbing foams is characterized by simplicity and speed. Self-adhesive products eliminate the need for additional fastening materials, significantly simplifying the mounting process. Surface preparation involves cleaning and degreasing the substrate before applying the material.

The steps for proper installation include:

- Preparation and cleaning of the mounting surface

- Planning panel placement considering room aesthetics

- Removing the protective film from the adhesive layer

- Carefully applying the material while eliminating air bubbles

- Pressing the entire surface to ensure a durable bond

Maintenance of installed foams is limited to periodic vacuuming and cleaning according to manufacturer recommendations, ensuring preservation of absorption properties over a long service life.

About ABM Insulation

ABM Insulation has operated as a reputable manufacturer and supplier of insulation materials since 2010. The company, located in Zabki near Warsaw, specializes in producing high-quality acoustic and thermal materials. Over a decade of experience translates into offering products that meet the highest quality and functional standards.

The company’s operations cover not only the Polish market but also cooperation with partners from European Union countries and the United States. Since 2012, the company has been steadily expanding its export activities, supplying its products to companies in Germany, the United Kingdom, Sweden, and the Netherlands. Strategic location and efficient logistics enable delivery within 24 hours of order placement.

Purchasing acoustic foam absorbers from ABM Insulation’s store guarantees receiving top-quality products along with professional technical support. The company offers personalized advice on selecting appropriate materials for specific applications.

Contact the ABM Insulation team of specialists for detailed information and consultations regarding the optimal acoustic solution for your project. Order products today and experience the effectiveness of professional acoustic solutions.

Selecting the Appropriate Foam Thickness for Specific Rooms

The effectiveness of acoustic insulation systems largely depends on matching material parameters to the specifics of a particular room. Each type of space features a unique acoustic profile resulting from its purpose, dimensions, finish, and types of sounds generated.

Professional selection of acoustic foam thickness requires frequency analysis of the room’s characteristics and identification of problematic spectral ranges. Different applications generate varying requirements, from controlling high frequencies in vocal booths to absorbing low frequencies in cinemas.

A systematic approach to material selection also considers practical aspects such as available installation space, aesthetic requirements, and project budget constraints.

Small Recording Rooms and Vocal Booths

Small recording rooms are characterized by a high level of acoustic reflections and a tendency to create standing waves in the mid- and high-frequency ranges. Vocal booths require special control of resonances within the frequency range of the human voice (85-255 Hz for fundamental tones and 2000-4000 Hz for harmonics).

Optimal solutions for small recording rooms:

- Thickness 20-30 mm – control of high-frequency reflections

- Coverage 40-60% of wall surfaces

- Combination with thinner materials on the ceiling

- Additional bass traps in corners

ABM Insulation acoustic foams with a thickness of 25 mm provide an optimal solution for most applications in small home studios and vocal booths.

Cinema Rooms and Home Theaters

Cinema rooms and home theaters have specific requirements for broadband acoustic absorption control. Audio systems in these spaces generate a full frequency spectrum, from deep bass effects to high-frequency dialogue and music.

The specification for cinema rooms includes:

- Low-frequency absorption (20-80 Hz) – thick foams 75-100 mm

- Mid-frequency control (200-2000 Hz) – foams 40-50 mm

- High-frequency reduction (4000-20000 Hz) – materials 20-30 mm

- Balanced reverberation time across the entire spectrum

Multilayer systems combining foams of different thicknesses provide optimal frequency characteristics for cinema applications.

Music Studios and Audiophile Rooms

Professional music studios require extremely precise acoustic control, enabling faithful reproduction and recording of sounds across the entire audible spectrum. Audiophile rooms have similar demands for acoustic neutrality and minimal distortion.

Key requirements for music studios:

- Flat frequency response of absorption

- Controlled dispersion of acoustic materials

- Elimination of reflection points in the listening area

- Phase optimization of absorption across different ranges

A combination of foams 30-40 mm thick with additional bass trap elements 75-100 mm thick ensures professional acoustic quality in music studios.

Commercial and Office Spaces

Commercial and office spaces require acoustic solutions that combine effectiveness with aesthetic and economic aspects. The main goal is to reduce background noise and improve speech intelligibility in the work environment.

The requirements for office spaces include:

- Speech frequency absorption (500-4000 Hz)

- Reduction of air conditioning noise (125-500 Hz)

- Control of acoustic reflections from hard surfaces

- Aesthetic integration with interior design

Acoustic foams with a thickness of 25-35 mm provide an optimal solution for most commercial applications, offering effective acoustic control at acceptable installation costs.

Tip: Before selecting the thickness of acoustic foam, it is recommended to conduct an acoustic analysis of the room or consult a specialist to identify the dominant frequencies requiring control.

Laboratory Measurements and Standards for Evaluating the Effectiveness of Acoustic Foams

An objective assessment of the effectiveness of acoustic foams is based on standardized measurement methods conducted under controlled laboratory conditions. International standards define precise testing protocols that enable consistent and reliable comparison of the properties of different materials and thicknesses.

Modern measurement methods take into account the spectral absorption characteristics, the impact of installation conditions, and the long-term stability of material properties. Laboratory test results form the basis for designing acoustic systems and verifying theoretical predictions regarding the influence of thickness on absorption efficiency.

Interpreting measurement data requires understanding testing methodologies and limitations of individual standards. Practical application of laboratory results in real installations may require consideration of additional environmental and structural factors.

Methods for Testing Sound Absorption Coefficient

The standard method for measuring the sound absorption coefficient uses a reverberation chamber technique according to ASTM C423. The test room with known acoustic characteristics is equipped with a sample of the tested material covering 72 square feet. Measuring reverberation time before and after installing the sample allows calculation of the absorption coefficient as a function of frequency.

The testing procedure includes the following steps:

- Chamber calibration without the material sample

- Sample installation according to standard procedure

- Reverberation time measurement at 16 measurement points

- Spectral analysis in one-third octave bands

- Calculation of absorption coefficients for each frequency

The results are presented as spectral graphs and NRC values averaged for frequencies 250, 500, 1000, and 2000 Hz.

ISO Standards and Other International Standards

The International Organization for Standardization (ISO) has developed a series of standards concerning acoustic measurements of absorbing materials. ISO 354 defines the method for measuring sound absorption in a reverberation chamber, while ISO 10534 describes the impedance tube method for small samples.

Main international standards include:

- ISO 354 – absorption in a reverberation chamber

- ISO 10534-1 – standing wave tube method

- ISO 10534-2 – transfer function method

- ASTM C423 – American reverberation chamber standard

- EN 1793-1 – European standard for acoustic barriers

Each standard features specific testing conditions and frequency ranges, which can affect comparability of results between different laboratories.

Interpretation of Measurement Results for Different Thicknesses

The analysis of acoustic absorption measurement results for foams of varying thickness requires consideration of the spectral characteristics and the material installation conditions. Increasing the thickness usually leads to a shift of the absorption maximum toward lower frequencies and an increase in the coefficient value in the low and mid-frequency ranges.

| Thickness [mm] | NRC | Maximum Absorption [Hz] | Effectiveness Range |

|---|---|---|---|

| 15 | 0.45 | 2000-4000 | High frequencies |

| 25 | 0.65 | 1000-2000 | Mid-high frequencies |

| 40 | 0.80 | 500-1000 | Broadband |

| 75 | 0.95 | 250-500 | Low-mid frequencies |

The interpretation of results must take into account the specifics of the intended application as well as the dominant frequencies requiring acoustic control.

Practical Application of Technical Data

Technical data from laboratory measurements form the basis for engineering acoustic calculations and insulation system design. However, practical application requires considering differences between laboratory conditions and real installations, which may affect the final material performance.

Factors influencing practical effectiveness include:

- Method of foam installation to the substrate

- Installation tightness and presence of acoustic bridges

- Environmental conditions (temperature, humidity)

- Interactions with other finishing elements

- Long-term aging of the material

Professional acoustic system design requires accounting for correction factors and safety margins when using laboratory data in practical calculations.

Tip: When selecting acoustic foam based on technical data, consider the actual installation conditions and consult with the material supplier to optimize the solution according to the specifics of the particular application.

Summary

The thickness of acoustic foams is a key parameter determining sound absorption efficiency across different frequency ranges. Thin materials with a thickness of 15-25 mm show the highest effectiveness in absorbing high frequencies, while thicker foams over 50 mm effectively control low frequencies and provide broadband absorption. An optimal thickness of 30-40 mm represents a compromise between effectiveness and cost for most commercial applications.

The physical mechanisms of sound absorption by acoustic foams are based on converting acoustic energy into heat through friction within the porous structure of the material. The interaction between thickness and density allows precise tuning of absorption properties to suit specific room characteristics. Professional laboratory measurements and international standards ensure an objective assessment of various solutions’ effectiveness.

The practical application of knowledge about how foam thickness affects sound absorption efficiency enables optimization of acoustic insulation systems both technically and economically. Conscious selection of materials with appropriate thickness, supported by technical data and professional advice, guarantees long-term investment effectiveness in room acoustic comfort.

Sources:

- https://www.sciencedirect.com/science/article/abs/pii/S0003682X19307510

- https://pmc.ncbi.nlm.nih.gov/articles/PMC9394424/

- https://acoustics.ippt.pan.pl/index.php/aa/article/view/2141

- https://ntrs.nasa.gov/api/citations/20110011143/downloads/20110011143.pdf

- https://acoustics.ippt.pan.pl/index.php/aa/article/download/459/390/767

- https://journals.pan.pl/Content/101625?format_id=1

- https://en.wikipedia.org/wiki/Absorption_(acoustics)

- https://simple.wikipedia.org/wiki/Acoustic_foam

- https://en.wikipedia.org/wiki/Acoustic_foam

- https://en.wikibooks.org/wiki/Engineering_Acoustics/Sound_Absorbing_Structures_and_Materials