Problems with excessive reverberation and acoustic disturbances affect both recording studio owners and residents of noisy apartments in city centers. Choosing the right soundproofing material is a key element in ensuring acoustic comfort. Acoustic foam, offered by ABM Insulation, is available in various thicknesses, which directly impacts its sound wave absorption properties.

Foam thickness determines the range of frequencies that the material effectively absorbs. Thin panels with a thickness of 10-20 millimeters mainly focus on high tones. Materials with a thickness of 50-75 millimeters provide universal use in most rooms. Products exceeding 100 millimeters in thickness specialize in controlling low frequencies, essential in music studios.

The foam’s mechanism of action involves dispersing acoustic energy within the material’s cellular structure. When a sound wave passes through the porous surface, part of the energy converts into heat through air molecule friction. The thicker the foam, the longer the path the wave travels, increasing energy absorption. Manufacturer ABM Insulation offers solutions ranging from 10 to 50 millimeters in thickness, tailored to diverse acoustic needs.

How foam thickness affects absorption of different sound frequencies

The relationship between material thickness and absorption effectiveness for specific frequency ranges results from the physical properties of sound waves. Low frequencies have long waves that require greater material depth for effective absorption. High tones, with short wavelengths, can be effectively dampened by thinner foam layers. Selecting the appropriate thickness should consider the dominant noise sources in a particular room.

Thin foams effective for high frequencies

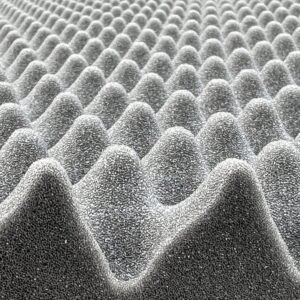

Materials with a thickness of 10-20 millimeters demonstrate high effectiveness at frequencies above 2000 Hz. ABM polyurethane foam with a thickness of 10 millimeters absorbs speech sounds and rustling noises, making it an ideal solution for open-plan offices. The absorption coefficient for this thickness reaches values of 0.7-0.9 in the high-frequency range. The material’s cellular structure effectively traps short acoustic waves without needing thicker layers.

Properties of thin acoustic foams:

- Thickness of 10 millimeters provides sound absorption above 2000 Hz at a level of 70-90 percent

- NRC coefficient for 10-millimeter materials ranges from 0.15 to 0.30

- Surface mass does not exceed 300 grams per square meter, facilitating installation

- The cost of ABM Insulation foam 10 millimeters starts at €14.75 per square meter

White ABM Insulation absorbing foam with a thickness of 20 millimeters offers better control of mid-tones while maintaining compact dimensions. The material is used in residential rooms where space is limited. The NRC value for 20-millimeter foams ranges from 0.3 to 0.5. Thin panels also have lower weight, making installation on walls and ceilings easier.

The use of thin foams includes acoustic correction of small office rooms and home rooms. The materials reduce reverberation caused by computers, keyboards, and phone conversations. In commercial spaces, thin panels minimize sound reflections from hard surfaces. The cost of ABM acoustic foam with a thickness of 10 millimeters starts at €14.75 per square meter.

Thick panels and low-frequency control

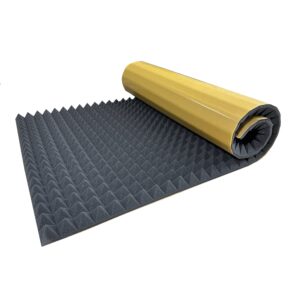

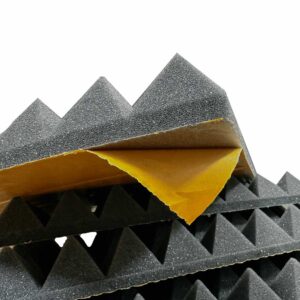

Acoustic foam with a thickness of 50 millimeters, available in the ABM Piramidki product line, effectively absorbs frequencies below 500 Hz. These materials achieve an absorption coefficient above 0.8 for low tones, eliminating dominant acoustic problems in recording studios. The pyramidal structure increases the effective surface area in contact with the sound wave, enhancing the absorption mechanism. The thickness of 50 millimeters allows control over bass resonances that accumulate in corners in smaller rooms.

Materials exceeding 100 millimeters are used as specialized bass traps. Basotect foam with a thickness of 10 centimeters absorbs 100 percent of acoustic energy at frequencies of 160 Hz and higher. Such solutions are essential in cinemas and concert halls. Material density at the level of 25 kg/m³ ensures an optimal balance between mass and absorbing properties.

Characteristics of bass traps:

- Thickness exceeding 100 millimeters controls frequencies from 80 Hz upwards

- Material density ranges from 25-30 kg/m³ for optimal effectiveness

- Bass trap volume should exceed 10,000 cubic centimeters

- NRC coefficient reaches values above 1.0 in the mid-frequency range

Installation of thick panels requires consideration of their volume within the room space. ABM Insulation acoustic foam Piramidki 50 millimeters is available in formats of 50×50 centimeters and 100×200 centimeters. The price for a panel measuring 100×100 centimeters is approximately €14.38. In rooms with high acoustic requirements, the total thickness of absorbing layers may exceed 15 centimeters.

Average Thicknesses for Universal Applications

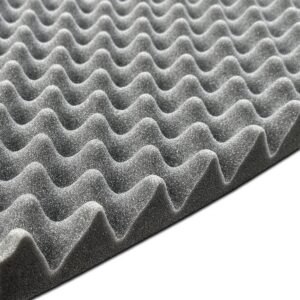

Foams with a thickness of 30-40 millimeters represent a compromise between effectiveness and material dimensions. The ABM Fala acoustic foam in the 40-millimeter version absorbs a wide frequency range from 250 to 4000 Hz. The NRC coefficient for this thickness reaches values of 0.6-0.8, providing noticeable acoustic improvement. This material is used in conference rooms where verbal clarity is required.

The wavy structure of ABM foam increases absorption efficiency by scattering sound reflections at different angles. A thickness of 30-40 millimeters allows for a reduction in reverberation time by 40-60 percent in a typical office room. This material also features better mechanical resistance compared to thinner variants. The self-adhesive version facilitates installation without the need for additional adhesives.

Applications of medium thickness include home theaters, music rooms, and educational spaces. ABM polyurethane foam at 30 millimeters costs approximately €22.50 per square meter. In residential rooms, this material reduces noise coming from neighboring units and corridors. The foam’s flexibility allows it to conform to irregular wall and ceiling surfaces.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

Noise Reduction Coefficient Depending on Material Thickness

The NRC coefficient is an averaged measure of a material’s ability to absorb sound in the frequency range from 250 to 2000 Hz. This value, expressed on a scale from 0 to 1, indicates what percentage of acoustic energy is absorbed. Foam thickness directly affects the NRC value, although the relationship is not linear. Materials thinner than 25 millimeters show a rapid increase in absorption with increasing thickness. Above 100 millimeters, the gain in effectiveness becomes less pronounced.

NRC Values for Foams up to 25 Millimeters Thick

Acoustic foam with a thickness of 10 millimeters achieves an NRC coefficient ranging from 0.15 to 0.30. This means the material absorbs 15-30 percent of sound energy in the key frequency band. ABM polyurethane foam at 10 millimeters has better properties for high tones, reaching absorption of 0.7 at 4000 Hz. In the low-frequency range, effectiveness drops to levels between 0.05 and 0.10.

Materials at 20 millimeters increase the average NRC coefficient to values between 0.30 and 0.50. The white absorbing ABM foam at this thickness improves speech intelligibility in office spaces. At a frequency of 1000 Hz, the absorption coefficient reaches levels of 0.5-0.6. Increasing thickness from 10 to 20 millimeters doubles absorption effectiveness in the mid-tone range.

Absorption parameters for thicknesses up to 25 millimeters:

-

NRC coefficient for 10 millimeters: 0.15-0.30 average absorption

-

NRC coefficient for 20 millimeters: 0.30-0.50 average absorption

-

Absorption at 4000 Hz for 20 millimeters: 0.80-0.98

-

Absorption at 250 Hz for 20 millimeters: 0.10-0.20

Foams with a thickness of 25 millimeters represent the threshold above which the benefits of further increasing thickness become more noticeable. The NRC coefficient for this thickness is about 0.40-0.55. This material is used in spaces requiring basic acoustic correction. The cost of ABM foam with a thickness of 20 millimeters starts at €18.75 per square meter in the self-adhesive version.

Absorption parameters for materials with thickness from 50 to 75 millimeters

Acoustic foam with a thickness of 50 millimeters achieves an NRC coefficient of 0.60-0.80. This material effectively absorbs frequencies from 200 Hz upwards, eliminating most acoustic problems in typical rooms. ABM Pyramid foam of 50 millimeters is characterized by absorption exceeding 0.9 for frequencies above 1000 Hz. In the low-frequency range, the coefficient is 0.30-0.50, which is a significant improvement compared to thinner variants.

A thickness of 75 millimeters increases the average NRC coefficient to values of 0.75-0.90. Materials of this thickness provide almost complete absorption in the mid and high frequency ranges. For tones at a frequency of 250 Hz, the absorption coefficient reaches levels of 0.60-0.70. The use of 75-millimeter foams is particularly justified in large volume rooms.

The difference in effectiveness between thicknesses of 50 and 75 millimeters is most noticeable in the low-frequency range. For a tone at a frequency of 125 Hz, the absorption coefficient increases from 0.15 to 0.35. ABM acoustic foam with a thickness of 50 millimeters in a format of 100×200 centimeters costs €28.62. Materials of this thickness require solid mounting due to greater surface mass.

Maximum panel effectiveness above 100 millimeters

Materials exceeding a thickness of 100 millimeters achieve an NRC coefficient above 0.90. Foam with a thickness of 10 centimeters shows an NRC value at the level of 1.15, which means a diffusion effect beyond mere absorption. Materials of this thickness absorb 100 percent of acoustic energy at frequencies above 160 Hz. In the lowest tone range, from 80 to125 Hz, the absorption coefficient reaches values between 0.50 and 0.70.

Bass traps measuring 30x25x25 centimeters, characterized by a volume over 10,000 cubic centimeters, effectively control low-frequency resonances. Material density of 25-30 kg/m³ ensures optimal absorption without excessive weight. The NRC coefficient for such solutions exceeds a value of1 .0 in the frequency band from500 to4000 Hz . These materials eliminate dominant acoustic problems in music studios.

The use of panels thicker than100 millimeters is mainly limited to room corners where low frequencies accumulate . Installation of such solutions requires modal analysisof the roomto determine optimal locations . The costof specialized bass trapsis about€10 per setof four elements . For standard acoustic foam ,thicknesses above50 millimetersare sufficientfor most applications.

Comparison of Average Values for Different Thickness Ranges

A comparison of absorption coefficients for various thicknesses of acoustic foam allows for an informed choice of material. The table below shows NRC values as a function of thickness at a frequency of 1000 Hz:

| Material Thickness | NRC Coefficient | Application |

|---|---|---|

| 10-20 mm | 0.20-0.40 | Offices, living rooms |

| 30-40 mm | 0.50-0.70 | Conference rooms, home theaters |

| 50-75 mm | 0.70-0.90 | Recording studios, rehearsal rooms |

| Over 100 mm | 0.90-1.15 | Bass traps, concert halls |

Increasing thickness from 20 to 50 millimeters doubles absorption effectiveness in the low-frequency range. Further increasing thickness to 100 millimeters provides an additional 30-40 percent increase. ABM acoustic foam offers solutions across the full range of thicknesses, tailored to specific needs.

The cost-effectiveness relationship is not linear. Materials with a thickness of 30-40 millimeters provide the best price-to-performance ratio for typical applications. ABM Wave foam, 40 millimeters thick, costs approximately €11.75 per panel in the self-adhesive version. Thickness selection should consider the dominant frequency range in the specific room.

Tip: Before purchasing thick foam, it is advisable to measure the room’s acoustics using a mobile app for frequency spectrum analysis.

Selecting the Appropriate Foam Thickness for a Specific Room

Selecting Acoustic Material Thickness requires analyzing several factors, including the room’s purpose, volume, and dominant noise sources. Office spaces have different acoustic challenges than recording studios. Ceiling height and room volume affect reverberation time and low-frequency resonances. Identifying main disturbance sources allows optimizing material selection for specific frequencies.

Offices and Conference Rooms

Open-plan office spaces require materials that reduce reverberation in the speech frequency range of 500-2000 Hz. Acoustic foam with a thickness of 20-30 millimeters effectively shortens reverberation time by 40-50 percent. ABM white absorbing foam, 20 millimeters thick, improves telephone conversation clarity. This material reduces reflections from hard wall and ceiling surfaces.

Acoustic Requirements for Offices:

- Reverberation reduction in the speech frequency range of 500-2000 Hz

- Reduction of reverberation time by at least 40 percent to improve intelligibility

- Covering 30-40 percent of ceiling surface with acoustic panels

- Use of materials 20-30 millimeters thick on partition walls

Conference rooms require higher acoustic parameters due to the need for precise verbal communication. Foam with a thickness of 40 millimeters eliminates echo and reverberation, improving video recording quality. ABM Wave foam, 40 millimeters thick in self-adhesive form, facilitates wall installation without damaging surfaces. The material costs about €11.75 per panel.

The placement of acoustic panels in offices should focus on areas with the highest traffic intensity. Walls behind workstations and ceilings above communication zones should take priority during installation. Covering 30-40 percent of ceiling surface noticeably improves acoustics. Materials with wavy or pyramid structures increase absorption efficiency.

Recording Studios and Music Rooms

Rooms used for music production require control of the entire frequency spectrum from 80 to 16,000 Hz. Acoustic foam with a thickness of 50 millimeters is the minimum for recording studios. ABM Piramidki 50 millimeter material eliminates the first sound reflections from walls, improving stereo image precision. The pyramidal structure increases the absorption surface without the need for thicker layers.

Room corners require specialized bass traps thicker than 100 millimeters. Low-frequency resonances accumulate at the junctions of three planes, disrupting sound neutrality. Using bass traps reduces the dominance of certain frequencies by 10-15 decibels. The material density of 25 kg/m³ ensures effective control of tones below 200 Hz.

Material placement in a recording studio:

- Side walls: 50-millimeter panels at first reflection points

- Corners: bass traps thicker than 100 millimeters

- Ceiling: materials 30-40 millimeters covering 40-50 percent of the surface

- Rear wall: diffusive or absorptive panels 40-50 millimeters thick

Music rehearsal rooms require a balance between absorption and natural sound. Excessive damping deprives instruments of natural reverberations. Foam with a thickness of 40-50 millimeters covering 40-50 percent of wall surfaces provides an optimal compromise. The cost of ABM Piramidki foam, 50 millimeters thick in a 100×100 centimeter format, is €14.38.

Performance Halls and Theaters

Large-volume rooms are characterized by long reverberation times requiring intensive absorption. Performance halls require materials with an NRC coefficient exceeding 0.80. Acoustic foam with a thickness of 50-75 millimeters provides effective acoustic control in such spaces. Materials mounted on ceilings and side walls reduce unwanted reflections.

Theaters require precise design of absorbing material placement. The front part of the audience area should remain more reflective to preserve natural sound. The rear part requires intensive absorption to eliminate echo. ABM acoustic foam with a wavy structure ensures controlled sound diffusion.

Acoustic systems in performance halls often combine foams of different thicknesses to control the entire frequency spectrum. Ceilings require materials 40-50 millimeters thick, while corners need solutions 100 millimeters thick or more. The total cost of acoustic adaptation for a large hall can exceed tens of thousands of euros. Consulting an acoustician helps optimize material selection.

Tip: Purchasing materials in larger sheets of 100×200 centimeters reduces the cost per square meter by about 20 percent compared to smaller formats.

The Relationship Between Thickness and Acoustic Wavelength

The acoustic wavelength determines the minimum dimensions of the material needed for effective absorption. A wave with a frequency of 100 Hz has a length of about 3.4 meters in air. Absorbing materials work most efficiently when their thickness corresponds to at least one quarter of the wavelength. For a frequency of 1000 Hz, the wavelength is 34 centimeters, which means an optimal material thickness of about 8.5 centimeters. Foam thinner than a quarter wavelength still absorbs sound but with less effectiveness.

The Mechanism of Sound Energy Absorption in Foam Cells

The cellular structure of acoustic foam creates a labyrinth of microscopic channels where the energy of the sound wave is dispersed. Air molecules moving inside the cells experience friction against the material walls. The kinetic energy of the wave converts into heat, reducing the sound amplitude. Cell density and size determine the range of frequencies that the material effectively absorbs.

Polyurethane foams have densities of 20-30 kg/m³ and cell diameters ranging from 0.5 to 2 millimeters. The smaller the cells, the more effective the absorption of high frequencies. Materials with larger cells handle low tones better. ABM Insulation acoustic foam uses an optimized cellular structure for a wide spectrum of frequencies.

The sound absorption process in foams:

- The acoustic wave penetrates the cellular structure of the material

- Air molecules oscillate inside the foam channels

- Friction against cell walls converts kinetic energy into heat

- The wave amplitude gradually decreases with penetration depth

The penetration depth of the wave into the material depends on the acoustic impedance of the foam. The higher the airflow resistance, the greater the energy absorption. Materials with too high density may reflect waves instead of absorbing them. The optimal density for polyurethane foams is 25-35 kg/m³. ABM foam meets these parameters, ensuring effective absorption.

Quarter Wavelength Distance from Wall

The quarter wavelength principle defines the optimal distance between absorbing material and a hard surface. For a frequency of 100 Hz, this distance is about 85 centimeters. Mounting foam directly on the wall reduces low-frequency absorption effectiveness. Leaving an air gap between the material and wall increases absorption efficiency by 20-30 percent.

A foam thickness of 50 millimeters mounted with a 5-centimeter gap from the wall achieves effectiveness comparable to an 80-millimeter-thick material mounted directly. The air gap acts as an additional absorbing layer. In practical applications, a gap of 3-5 centimeters represents a compromise between effectiveness and space. ABM Insulation acoustic foam in self-adhesive version can be mounted on spacer strips.

Quarter-wave resonators use enclosed air spaces to enhance the absorption of specific frequencies. A box with a depth of 85 centimeters filled with foam absorbs the 100 Hz frequency with maximum efficiency. Tuning the resonators to the dominant acoustic problems of the room requires spectral measurements. The cost of building specialized resonators exceeds standard solutions.

The impact of material density on absorption efficiency

The density of acoustic foam affects airflow resistance and the acoustic impedance of the material. Materials with a density below 20 kg/m³ show low absorption effectiveness due to insufficient resistance. Foams with a density of 25-30 kg/m³ provide an optimal balance between absorption and weight. Further increasing density above 40 kg/m³ reduces effectiveness because the material begins to reflect waves instead of absorbing them.

The 25 kg/m³ density used in ABM acoustic foams guarantees an NRC rating between 0.70 and 0.90 for a thickness of 50 millimeters. Lower-density materials require greater thickness to achieve similar parameters. A cellular structure with optimal density ensures even absorption across a wide frequency range. ABM insulation rubber foam features higher density, which increases thermal insulation effectiveness.

The relationship between density and effectiveness is not linear. Increasing density from 25 to 30 kg/m³ improves absorption by about 10 percent in the low-frequency range. Further increases in density bring marginal benefits with significant increases in cost and material weight. Selecting the optimal density should consider the specific application.

Tip: Mounting foam on wooden frames spaced 5 centimeters from the wall increases low-frequency absorption efficiency without needing thicker material.

Practical applications of foams of varying thickness in acoustic control

Planning acoustic material installation requires identifying problematic areas in the room. Corners accumulate low frequencies that require specialized solutions. Parallel walls generate standing acoustic waves that disrupt sound uniformity. Ceilings are a key element of the acoustic system, especially in large-volume rooms. Combining materials of different thicknesses allows control over the entire frequency spectrum.

Bass traps in room corners

Room corners are places where low frequencies accumulate due to overlapping waves reflected from three surfaces. Materials thicker than 100 millimeters effectively absorb tones below 200 Hz. Bass traps installed in corners reduce dominance of certain frequencies by 10-15 decibels. The triangular structure of elements allows maximum use of space.

Specification of effective bass traps:

- Minimum volume: 10,000 cubic centimeters of absorbing material

- Filling density: 25-30 kg/m³ for optimal absorption

- Element height: minimum 100 centimeters for frequency control below 80 Hz

- Effective absorption range: from 50 Hz to 10,000 Hz

The volume of the bass trap determines the lowest frequency it effectively absorbs. An element measuring 30x25x25 centimeters with a volume of 10,935 cubic centimeters controls frequencies from 80 Hz upwards. A material density of 25 kg/m³ ensures optimal absorption without excessive weight. Installing traps in the four corners of the room improves sound uniformity.

ABM acoustic foam with a thickness of 50 millimeters can be shaped into triangular bass traps. This material provides effective frequency control above 120 Hz with smaller dimensions. The cost of standard bass traps is about 10 EUR for a set of four elements. Building traps yourself from ABM foam reduces costs by half.

Wall panels for reverberation reduction

Installing acoustic panels on walls is a fundamental method to improve room acoustics. Foam with a thickness of 30-40 millimeters covering 30-40 percent of wall surfaces reduces reverberation time by 40-60 percent. The placement of the material should focus on first reflection points. Walls behind sound sources and opposite the listener take priority.

ABM Wave acoustic foam, 40 millimeters thick in a self-adhesive version, facilitates installation without damaging wall surfaces. The wavy structure of the material increases absorption efficiency by scattering reflections at different angles. The cost to cover a wall area of 10 square meters is about 117.50 EUR. Installation takes about 2-3 hours without the need for specialized tools.

Panels installed in a checkerboard pattern provide a balance between absorption and natural sound quality. Full coverage of walls with absorbing material can overly dampen the room. Leaving 40-50 percent reflective surface preserves natural reverberation. ABM Pyramid acoustic foam, 50 millimeters thick in a 50×50 centimeter format, facilitates creating checkerboard patterns.

Acoustic ceilings in public spaces

Ceilings are a key element of the acoustic system in large-volume rooms. Open space offices require intensive ceiling absorption to reduce sound transmission between workstations. Acoustic foam with a thickness of 20-30 millimeters mounted on ceilings reduces noise levels by 8-12 decibels. Materials with wavy or pyramid structures increase efficiency while maintaining aesthetics.

White ABM absorbing foam, 20 millimeters thick, provides a discreet appearance in office spaces. The cost to cover a ceiling area of 20 square meters is about 375 EUR. Installing self-adhesive foam on the ceiling requires mechanical fastening such as anchors or strips. Conference rooms require materials with a thickness of 40 millimeters to ensure optimal acoustics.

Advantages of acoustic ceilings:

- Reduction of noise level by 8-12 decibels in office spaces

- Improvement of speech intelligibility by shortening reverberation time

- Even distribution of absorption throughout the entire room space

- Aesthetic finish maintaining visual consistency of the interior

Suspended ceiling systems filled with acoustic foam achieve an NRC rating above 0.90. The air gap between the ceiling and the slab increases the effectiveness of low-frequency absorption. The cost of a comprehensive acoustic ceiling system exceeds 50 EUR per square meter. ABM Insulation acoustic foam is an economical alternative to more expensive systems.

Combinations of different thicknesses for optimal effect

Combining foams of various thicknesses allows precise control over the entire frequency spectrum. Walls require materials 30-40 millimeters thick to reduce mid and high tones. Corners need bass traps 100 millimeters thick or more. Ceilings can be covered with thinner foam, 20-30 millimeters, due to ease of installation.

A recording studio with a volume of 40 cubic meters requires about 15-20 square meters of 50-millimeter foam on the walls. Four bass traps measuring 30x30x100 centimeters control low-frequency resonances. A ceiling covered with 30-millimeter foam over an area of 8-10 square meters complements the acoustic system. The total cost of ABM materials for such a studio is approximately 375-500 EUR.

An office with an area of 50 square meters requires covering the ceiling with 20-millimeter foam over an area of 15-20 square meters. Partition walls can be additionally equipped with 30-millimeter panels in strategic locations. The total cost of acoustic adaptation for such an office using ABM materials is about 500-625 EUR. The effect of improved acoustics is noticeable after covering just 30 percent of the surface.

Tip: Starting installation from corners and first reflection points yields the fastest results with minimal material usage.

FAQ: Frequently Asked Questions

What is the minimum thickness of acoustic foam to use in a home recording studio?

A home recording studio requires material at least 50 millimeters thick for effective acoustic control. Thinner options focus only on high frequencies, neglecting the crucial midrange band. The 50-millimeter foam absorbs sounds from 200 Hz upwards, eliminating most acoustic problems. The pyramidal structure increases absorption surface area, enhancing material effectiveness.

Corners require thicker solutions exceeding 100 millimeters. Bass resonances accumulate precisely at plane junctions. Bass traps reduce dominance of certain frequencies by 10-15 decibels. Covering 40-50 percent of wall surfaces with 50-millimeter foam provides an optimal balance between absorption and natural instrument sound.

Is a thickness of 20 millimeters sufficient to improve the acoustics of an open space office?

Acoustic foam with a thickness of 20 millimeters effectively reduces reverberation in the speech frequency range of 500-2000 Hz. The material absorbs sounds from phone conversations, keyboards, and other typical office noise sources. The NRC rating for this thickness ranges from 0.30 to 0.50, providing a noticeable improvement in verbal communication clarity. Installation on ceilings yields better results than placing it solely on walls.

Key installation parameters:

- Covering 30-40 percent of the ceiling surface with absorbing material

- Reducing reverberation time by 40-50 percent in a typical office space

- Noise level reduction by 6-8 decibels with optimal panel placement

Partition walls can be additionally equipped with 30-millimeter panels to increase effectiveness. The total cost of acoustic adaptation for a 50 square meter space using materials with a thickness of 20 millimeters is approximately 375-500 EUR.

Why do thicker foams absorb low frequencies better than thin materials?

The wavelength of sound determines the minimum dimensions of material needed for effective absorption of sound energy. A wave at 100 Hz has a length of about 3.4 meters in air. Absorbing materials work most efficiently when their thickness corresponds to at least one-quarter of the wavelength. For a 100 Hz tone, this means a minimum thickness of 85 centimeters, although thinner materials still absorb sound with less effectiveness.

Ten-millimeter foam absorbs only 5-10 percent of the energy of a 100 Hz wave. Fifty-millimeter material increases absorption to 30-50 percent for the same frequencies. Thickness above 100 millimeters provides almost complete control over tones below 200 Hz. The cellular structure of the foam converts the kinetic energy of the wave into heat through friction between air molecules and the material walls.

How does the NRC rating change when increasing foam thickness from 30 to 75 millimeters?

The NRC rating rises from values between 0.50-0.70 for thicknesses of 30-40 millimeters to levels between 0.75-0.90 at a thickness of 75 millimeters. The increase in effectiveness is especially noticeable in the low-frequency range of 125-250 Hz. Thirty-millimeter material absorbs about 20 percent of energy at 125 Hz, while the 75-millimeter variant achieves absorption levels of 35-40 percent. The difference becomes less pronounced at frequencies above 1000 Hz, where both materials absorb over 80 percent of acoustic energy.

The increase in NRC rating is not linear relative to material thickness. Doubling thickness from 30 to 60 millimeters increases effectiveness by about 40 percent; however, further increasing it to 120 millimeters yields only an additional 20-25 percent absorption. The cost-to-performance ratio makes materials between 30 and 40 millimeters offer the best efficiency-to-price balance for typical applications.

Does installing acoustic foam with a gap from the wall increase sound absorption effectiveness?

An air gap between the foam and the wall increases low-frequency absorption efficiency by 20-30 percent. A 50-millimeter material installed with a 5-centimeter gap achieves effectiveness comparable to an 80-millimeter foam mounted directly on the surface. The quarter-wave principle determines the optimal distance, which for a frequency of 100 Hz is about 85 centimeters. In practical applications, a gap of 3-5 centimeters is a compromise between effectiveness and available room space.

Installation on wooden frames or spacer strips allows easy creation of the gap. Self-adhesive foam requires additional spacer pads to maintain the distance. Installation costs increase by about 15-20 percent compared to direct mounting.

Benefits of installation with a gap:

- Improved low-frequency absorption without increasing material thickness

- Easier panel replacement without damaging wall surfaces

- Allows air circulation preventing moisture buildup behind the foam

Quarter-wave resonators use enclosed air spaces to enhance absorption of specific frequencies. A box 85 centimeters deep filled with foam absorbs the 100 Hz frequency with maximum efficiency.

Summary

The thickness of acoustic foam is a key parameter determining sound absorption effectiveness across different frequency ranges. Materials 10-20 millimeters thick focus on high frequencies, while panels 50-100 millimeters thick control low frequencies. The NRC coefficient increases with thickness, reaching values exceeding 0.90 for materials over 100 millimeters thick. ABM Insulation acoustic foam offers solutions ranging from 10 to 50 millimeters in thickness, tailored for various applications.

Selecting the appropriate thickness requires analysis of the room’s purpose and dominant noise sources. Offices and conference rooms require materials 20-40 millimeters thick, while recording studios need at least 50 millimeters thickness. Combining foams of different thicknesses in strategic locations provides optimal acoustic control with rational material use. The quarter-wave principle and the impact of material density on absorption effectiveness form the theoretical basis for designing acoustic systems.

Practical applications include bass traps in corners, wall panels, and acoustic ceilings. ABM Insulation self-adhesive foam facilitates installation without specialized equipment. The cost of acoustic adaptation for a typical room using ABM materials ranges from EUR 375 to EUR 625. Investing in properly selected acoustic foam significantly improves comfort and sound quality in any room.

Sources:

- https://en.wikipedia.org/wiki/Noise_reduction_coefficient

- https://www.sciencedirect.com/topics/engineering/sound-absorption

- https://advanced.onlinelibrary.wiley.com/doi/10.1002/advs.202501898

- https://www.reddit.com/r/Acoustics/comments/uxduev/about_the_thickness_of_acoustic_panels/

- https://www.acoustic-supplies.com/absorption-coefficient-chart/

- https://acoustics.ippt.pan.pl/index.php/aa/article/view/3149

- https://www.sciencedirect.com/science/article/pii/S0264127524009158

- https://www.sciencedirect.com/science/article/pii/S0003682X21000578

- https://bioresources.cnr.ncsu.edu/resources/comparison-of-the-sound-absorption-properties-of-acoustic-absorbers-made-from-used-copy-paper-and-corrugated-board/

- https://bioresources.cnr.ncsu.edu/resources/evaluation-and-comparison-the-properties-of-acoustic-boards-made-of-date-palm-fiber/