Air conditioning systems in residential and commercial buildings have become a standard of modern construction. Cooling devices provide thermal comfort during heat waves and stabilize air humidity. However, the operation of air conditioners generates noise that significantly disturbs the peace inside rooms. Rubber foam is an effective solution to this problem, absorbing vibrations and reducing unpleasant sounds from the installation.

Ventilation systems emit various sounds during daily operation. Compressors produce low vibrations, fans generate characteristic air noise. Pipes transporting the refrigerant carry sounds throughout the building structure. Acoustic insulation of spaces equipped with HVAC devices directly affects residents’ quality of life and employees’ work efficiency.

Effective soundproofing of air conditioning requires the use of specialized materials with sound-absorbing properties. Absorbing foams eliminate acoustic wave energy and reduce reverberation time in rooms. Using appropriate insulation simultaneously increases the thermal efficiency of the entire cooling system. Materials available in ABM Insulation’s offer combine acoustic functions with thermal insulation properties, providing comprehensive protection for installations.

Noise sources originating from air conditioning devices

HVAC systems consist of numerous mechanical and electrical components that generate sounds during operation. Each component of the cooling installation emits specific noises at different frequencies. Understanding the mechanisms of noise generation enables effective problem reduction. Locating main sound sources is the first step toward improving acoustic parameters of rooms.

Air conditioning devices generate noise with variable frequency characteristics. Low tones mainly come from compressors and electric motors. High frequencies arise during airflow through narrow sections of ventilation ducts. Medium tones are generated by fans and moving parts in indoor units.

The sound of air flowing through ventilation grilles

The air moving in ventilation systems creates characteristic aerodynamic noise. Sudden changes in flow direction cause turbulence formation. Narrow duct sections and sharp edges intensify the acoustic effect. Metal ventilation grilles further amplify frequencies audible to humans.

The speed of air masses directly affects the level of generated sound. Exceeding 3 meters per second in ventilation ducts produces noticeable noises. Incorrect duct sizing exacerbates acoustic problems in installations. Too small cross-sections force higher flow speeds, which increase noise.

Regular cleaning of air filters significantly reduces flow noise in the system. Accumulated dust decreases the effective cross-sections of ventilation ducts. Increased flow resistance forces higher fan speeds, which intensifies noise emission. Periodic maintenance of the installation keeps acoustic parameters at an acceptable level for many years of operation.

Vibrations of compressors and internal unit fans

Refrigeration compressors are the main source of mechanical vibrations in air conditioning systems. Reciprocating models produce pulsating vibrations with characteristic low frequencies. Scroll compressors operate more quietly but still generate noticeable vibrations during operating cycles. Unbalanced fan blades exacerbate the acoustic problems of the entire installation.

Mechanical vibrations are transmitted through the building structure over considerable distances. Materials such as concrete and steel effectively conduct vibrations between floors. Internal unit housings act as resonating membranes, amplifying sounds. Installing devices without using damping pads increases noise emission into rooms.

Elements generating vibrations in air conditioning:

- Unbalanced axial and centrifugal fan rotors

- Worn bearings in drive electric motors

- Reciprocating compressors operating without damping systems

- Loose metal housing fastening elements of units

- Circulation pumps in water cooling systems

Inadequate vibration damping leads to premature wear of mechanical air conditioner components. Continuous vibrations weaken screw connections and welds in unit structures. Metal refrigerant pipes undergo material fatigue due to cyclic stresses. Professional anti-vibration pads made of rubber or silicone effectively isolate devices from the building structure. Application of damping mats on housings reduces vibration amplitude by 60 to 80 percent. Regular inspection of fastenings prevents increasing acoustic problems during system operation.

Sounds of refrigerant operation in copper pipes

The refrigerant flowing through pipes produces specific noises during phase changes. Transitions between liquid and gas phases intensify noise generation in the ducts. Expansion valves cause sudden pressure drops that can be heard inside rooms. Turbulent flow at pipe constrictions creates high-frequency noise.

Copper pipes effectively transmit sounds to the building’s wall and ceiling structures. Lack of proper acoustic insulation for ducts amplifies this negative effect. Pipe mounting points act as acoustic bridges, transmitting vibrations. The thermal expansion of copper causes characteristic cracking sounds during system cycles.

Proper installation design significantly reduces refrigerant noise. Smooth pipe bends eliminate sudden changes in medium flow direction. Flexible mounts prevent vibration transmission to structural elements. Rubber foam available from ABM Insulation effectively dampens sounds in freon ducts.

Resonance of Metal Enclosures During Operating Cycles

Metal enclosures of air conditioners act like resonant boxes, amplifying sounds. Thin steel sheets easily vibrate due to the internal components’ vibrations. The natural frequency of the enclosures often matches the operating parameters of the devices. The resonance phenomenon significantly increases the noise level emitted to the surroundings.

Insufficient stiffening of enclosure structures worsens the acoustic parameters of the installation. Large flat metal surfaces vibrate most intensely during compressor operation. Component mounting points transmit vibrations to the entire metal structure. Aging devices and corrosion increase the amplitude of resonant vibrations of the enclosures.

Lining the interiors of enclosures with damping materials effectively eliminates resonance problems. Butyl mats absorb mechanical vibrations of metal surfaces, reducing noise. ABM Insulation offers specialized anti-resonance materials with high effectiveness. Proper placement of vibration dampers completely removes acoustic issues in air conditioning installations.

Mechanism of Acoustic Foam in Air Conditioning Noise Reduction

Sound-absorbing materials utilize advanced physical properties of open or closed-cell structures. The mechanism of acoustic energy absorption is based on several simultaneous physical phenomena. Understanding how foams work allows their optimal application in various parts of an installation. The effectiveness of noise reduction directly depends on material parameters and sound frequency.

Acoustic waves lose their kinetic energy when encountering foam structure. Internal friction processes convert mechanical vibrations into minimal amounts of heat. The cellular structure of the material determines absorption efficiency across different noise frequency ranges. Proper selection of insulation layer thickness maximizes effectiveness at optimal costs.

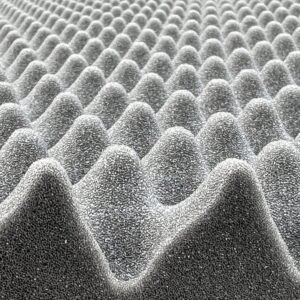

Porous Structure Absorbing Sound Wave Energy

Acoustic foam is characterized by a specific open-cell structure with high porosity. Connected pores create a complex labyrinth of microscopic channels. Air filling the cells vibrates under incoming acoustic waves. Friction between air particles and pore walls absorbs and disperses sound energy.

The material’s density directly affects effective attenuation across various frequencies. Smaller pores more efficiently absorb high-frequency sounds. Larger cells better reduce low-frequency noise from installations. A varied foam structure provides broadband absorption of acoustic energy ranging from 250 to 4000 Hz.

Polyurethane foam from ABM Insulation’s offer has an optimized pore structure ensuring high effectiveness. The material excellently dampens noise within the most important frequency range for air conditioning systems. The self-adhesive layer significantly facilitates installation on various surfaces. The white foam aesthetically harmonizes with residential and office interiors.

Acoustic Absorbing Soundproofing Foam in the ABM Insulation store

Conversion of Mechanical Vibrations into Heat in Foam Cells

Mechanical vibrations transmitted to the foam structure are effectively dissipated within the material. The elastic cell walls deform under cyclic mechanical stresses. Internal friction within the material generates minimal, immeasurable amounts of heat. This process irreversibly removes acoustic energy from the propagating sound wave.

The material loss factor precisely determines the efficiency of converting mechanical energy into thermal energy. Higher values of this parameter indicate significantly better vibration damping properties. Polyurethane foams feature very favorable mechanical loss parameters. Operating temperature within the standard range does not negatively affect absorption effectiveness.

The energy dissipation mechanism works independently of the direction of the acoustic wave incidence on the surface. The isotropic foam structure absorbs sounds coming from all directions simultaneously. The material effectively dampens both airborne noise and structural vibrations. Rubber foams offered by ABM Insulation additionally reduce vibration transmission through building structural elements.

Reduction of Reverberation Time in Rooms with Active Systems

Reverberation time defines the period during which sound persists in a room after the source is turned off. Spaces with hard surfaces are characterized by long acoustic reverberation times. Reflections of acoustic waves from walls, ceilings, and floors accumulate background noise. Absorbing materials significantly shorten sound decay time in enclosed spaces.

HVAC systems operate almost continuously, generating constant background noise. Long acoustic reverberation significantly amplifies the subjective perception of HVAC system loudness. Applying sound-absorbing foams on room surfaces effectively reduces this negative effect. Absorbing initial reflections of acoustic waves from walls yields the best practical results.

Parameters affecting reverberation time:

- Room volume and interior shape

- Surface area of sound-absorbing materials in the space

- Type of wall, ceiling, and floor finishes

- Amount of furniture and other objects in the room

- Sound frequency affecting absorption

Optimal reverberation times for various rooms are regulated by international building acoustic standards. Offices should achieve reverberation times below 0.6 seconds for frequencies from 500 to 2000 Hz. Conference rooms require even shorter times from 0.4 to 0.5 seconds. Residential rooms reach acoustic comfort at values below 0.5 seconds. Acoustic foams installed on 25 to 35 percent of wall surfaces effectively reduce reverberation. Positioning absorbing materials opposite noise sources maximizes reduction efficiency. Combining HVAC insulation with foam application on walls ensures excellent acoustic parameters.

Effectiveness in Low and Mid-Frequency Noise

Air conditioning units primarily emit low and mid-frequency sounds during operation. The range from 100 to 2000 Hz poses the greatest acoustic challenge for HVAC systems. Standard building materials absorb low-frequency noise very poorly. Specialized acoustic foams effectively reduce the most problematic sound frequencies.

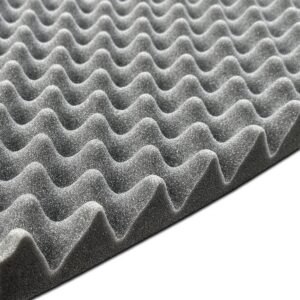

The thickness of the insulation layer directly affects the range of tones effectively dampened. Thinner foams, 10 to 20 mm thick, mainly absorb mid and high frequencies. Thicker layers from 30 to 50 mm efficiently suppress troublesome low tones. Acoustic foam with a pyramid structure significantly increases the effective absorption surface of the material.

Combining foams of different thicknesses in one insulation system maximizes damping effectiveness. A thinner layer placed on the outside absorbs high-frequency air noise. A thicker layer on the inside reduces low-frequency mechanical vibrations. This combination provides broadband acoustic protection for air conditioning systems.

Tip: Using 30 mm thick foam in ventilation ducts and 20 mm on unit housings ensures optimal noise reduction at reasonable material costs.

Strategic Application Points for Foams in Refrigeration Systems

The location of insulation materials determines the actual effectiveness of noise level reduction. A detailed analysis of sound sources allows precise identification of critical points requiring insulation. Applying foam directly at noise emission points yields the best possible results. A comprehensive approach to acoustic insulation of all components ensures maximum acoustic comfort.

Indoor units of split air conditioners require special attention during acoustic insulation. Air ducts effectively transmit sounds over long distances within a building. Pipes carrying refrigerant act as conductors of mechanical vibrations. Acoustic insulation of all key system components completely eliminates excessive noise problems.

Insulation of Air Ducts Behind Wall-Mounted Units

Ventilation ducts are the main pathway for noise propagation from indoor units. Aluminum or steel pipes transmit sounds very effectively to other rooms. The resonance of long ducts amplifies certain sound frequencies. Lining duct interiors with absorbing materials completely eliminates this acoustic problem.

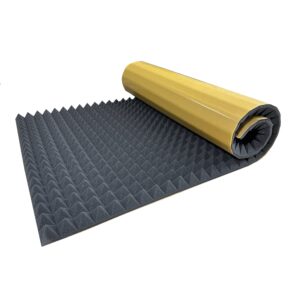

Rubber foam equipped with a self-adhesive layer significantly facilitates installation inside ventilation ducts. Material thickness from 6 to 10 mm effectively dampens airflow noise. The closed-cell structure prevents moisture absorption from the air. Foam flexibility allows precise fitting to irregular duct shapes.

External insulation of ventilation ducts additionally reduces noise emission into rooms. Wrapping the ducts with a thicker layer of foam effectively dampens vibrations of the metal walls. Mounting the ducts with flexible pads breaks acoustic sound bridges. Comprehensive internal and external insulation completely eliminates noise transmitted through the installation.

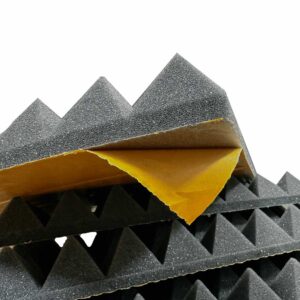

Lining external housings of split air conditioners

The housings of outdoor air conditioning units emit a high level of noise during operation. Compressors and fans generate intense vibrations transmitted to metal sheets. Resonance of thin housing surfaces significantly amplifies emitted sounds. Applying damping materials inside the housings effectively reduces noise emission.

Butyl mats very effectively eliminate resonant vibrations of steel housing sheets. The self-adhesive layer allows easy and quick installation on vertical surfaces. Thickness from 2 to 3 mm is fully sufficient to dampen vibrations of metal components. The material is resistant to changing weather conditions and retains its properties for many years.

The layer of acoustic foam applied over the butyl mat absorbs airborne noise emitted by fans. The combination of different materials with complementary properties maximizes insulation effectiveness. Covering 70 to 80 percent of the internal housing surface provides optimal results. Leaving free spaces ensures proper ventilation of operating components.

Butyl Soundproofing Mats ABM Professional in the ABM Insulation store

Installation on refrigerant pipes and condensers

Pipes transporting refrigerant effectively transmit vibrations to the entire building structure. Points where pipes pass through walls or ceilings act as sound amplifiers. Pipeline insulation completely eliminates structural noise transmission. Damping materials also protect pipes against thermal losses.

Thermal insulating rubber foam covered with aluminum foil perfectly combines acoustic and thermal functions. Closed cells in the material effectively prevent moisture condensation on cold pipes. The foam’s flexibility compensates for thermal deformations of pipes during system operation. Easy installation is enabled by ready-made sleeves with diameters matched to standard installations.

Key points requiring pipe insulation:

- Pipeline passages through walls and building ceilings

- Sections of pipes running along structural elements

- Flexible connections between indoor and outdoor units

- Expansion valves and desiccant filters in the refrigerant circuit

- Condensers and evaporators in complete units

Proper insulation of freon pipes requires particular care to ensure the tightness of connections between segments. All joints of rubber sleeves must be carefully sealed with specialized aluminum tape resistant to temperature. Unprotected gaps allow moisture penetration and loss of the thermal insulation properties of the protective layer. Pipe sections subjected to high mechanical stress require additional reinforcement with plastic clamps. The surface temperature of uninsulated pipes may fall below the air dew point, causing intense condensation. Regular inspection of insulation condition every 12 months allows detection of damage before serious corrosion problems develop.

Protecting ventilation grilles from noise emission

Ventilation grilles are the final point of noise emission from the system into rooms. The airflow striking the louvers generates characteristic aerodynamic noise. Vibrations of metal slats further amplify the unpleasant acoustic effect. Applying foam directly behind the grilles significantly reduces the emitted sound level.

Thin acoustic foam with a thickness from 10 to 15 mm does not restrict airflow. Installing the material with a minimal gap from the grilles prevents blocking ventilation openings. Dark colors of the foam aesthetically complement metal grilles. Easy replacement of the material during renovations or system upgrades is an additional advantage.

Grilles made of high-quality plastic generate significantly less noise than metal ones. Special models equipped with built-in acoustic dampers reduce noise even more. Combining appropriately selected grilles with foam insulation yields excellent acoustic results. Regular replacement of dirty air filters maintains a low system noise level.

Tip: Applying a thin layer of rubber foam on the back side of metal grilles completely eliminates vibrations and buzzing of components during intensive fan operation.

Combining acoustic insulation with thermal insulation of systems

Air conditioning systems absolutely require effective thermal insulation for all pipes transporting refrigerant. Heat losses through pipeline walls significantly reduce the energy efficiency of the entire cooling system. Materials that intelligently combine acoustic and thermal insulation properties optimize system parameters. Comprehensive thermal and acoustic insulation reduces operating costs and increases user comfort.

Thermal insulating foams characterized by a closed-cell structure effectively eliminate thermal bridges in the installation. The very low thermal conductivity of the material limits heat exchange with the environment. Acoustic properties of rubber foams simultaneously dampen noise emitted by the system. One universal material effectively fulfills two key insulating functions.

Reducing Cold Losses on Pipe Surfaces

Pipes transporting cold refrigerant absorb heat intensively from the surrounding air. Uninsulated pipelines cause significant energy losses that reduce system efficiency. The surface temperature of the pipes can be 20 to 30 degrees lower than the ambient temperature. Effective thermal insulation completely eliminates unnecessary thermal load on the compressor.

Rubber foam with a thickness of 13 to 19 mm very effectively protects pipes against heat loss. A thermal conductivity coefficient below 0.040 W/mK ensures high thermal insulation efficiency. The closed-cell structure effectively blocks heat flow through the material layer. Long-term parameter stability guarantees durable thermal protection for many years of operation.

The thickness of the insulation layer is precisely selected based on the pipeline diameter and refrigerant temperature. Smaller pipes with a diameter up to 20 mm require thinner insulation. Main lines with large diameters need thicker foam layers. The refrigerant temperature directly affects the required thickness of thermal protection.

Preventing Moisture Condensation Under the Foam Layer

Cold surfaces of refrigeration pipes cause intense condensation of water vapor from the surrounding air. Moisture accumulating under the insulation layer systematically damages materials and building structures. The growth of mold and fungi in damp areas poses a serious health risk to occupants. Proper vapor barrier insulation completely eliminates the dangerous problem of condensation.

The closed-cell structure of rubber foam very effectively blocks water vapor diffusion. A diffusion resistance factor exceeding 5000 provides a reliable vapor barrier. Tight connections between successive insulation segments prevent moisture from penetrating under the foam. Aluminum foil on the outer surface of the foam further increases the vapor tightness of the entire layer.

Proper installation of vapor barrier insulation requires great care and precision. All gaps between foam segments must be sealed with specialized tape without exception. Points where pipes pass through building partitions require particularly thorough sealing. Checking the tightness of all connections effectively prevents future moisture condensation problems.

Stabilizing Air Temperature Supplied to Rooms

Ventilation ducts carrying cold air absolutely require effective thermal insulation. Ducts running through unheated building spaces lose cold intensively to their surroundings. The air temperature at the outlet can be several degrees higher than at the inlet. Thermal insulation of ducts effectively stabilizes the parameters of supplied air.

Thermal insulating foams with a thickness of 20 to 30 mm very effectively protect ventilation ducts against losses. The material simultaneously dampens noise from flowing air, serving a dual function. The self-adhesive layer facilitates installation on round and rectangular ventilation ducts. Foam flexibility allows for tight fitting in hard-to-reach places.

Stable air temperature significantly improves the perception of thermal comfort in air-conditioned rooms. Eliminating temperature fluctuations reduces the load on indoor air conditioning units. Lower electricity consumption directly translates into real financial savings. Comprehensive thermal and acoustic insulation of the air conditioning system quickly pays off the investment costs.

Tip: Using foam with aluminum foil on the external sections of ducts additionally protects the system from heating caused by intense solar radiation during the summer.

Long-term effects of improved comfort in air-conditioned interiors

Effective acoustic insulation of air conditioning systems brings measurable benefits throughout the entire lifespan of the system. Significant noise reduction improves residents’ quality of life and employee efficiency. Better thermal parameters of the system lower monthly electricity bills. Investing in high-quality insulation materials pays off multiple times in the long term.

Building regulations and acoustic standards specify maximum allowable noise levels in various types of rooms. Exceeding these limits causes discomfort for residents and numerous complaints from building users. Proper acoustic insulation of ventilation systems ensures full compliance with applicable regulations. Property owners avoid costly legal and financial problems.

Improved employee concentration with consistently low noise levels

Background noise in office spaces significantly disrupts focus during work. Levels exceeding 40 dB clearly reduce mental work efficiency requiring concentration. Air conditioning systems often generate sounds far above this safe threshold. Soundproofing HVAC installations greatly improves working conditions in offices.

Numerous scientific studies show a direct link between noise levels and productivity of mental workers. Reducing sound levels by 10 dB increases work efficiency by 5 to 8 percent. A quiet work environment effectively lowers perceived stress and fatigue levels. Employees make significantly fewer mistakes in tasks requiring prolonged concentration.

| Noise Level | Impact on Work | Performance Reduction | Recommended Actions |

|---|---|---|---|

| Below 35 dB | Comfortable Conditions | No Impact | Maintain Parameters |

| 35 to 45 dB | Mild Disturbances | 5 to 10% | Basic Insulation |

| 45 to 55 dB | Significant Disturbances | 10 to 20% | Enhanced Insulation |

| Above 55 dB | Harmful Conditions | Above 20% | Urgent Modernization |

Chronic exposure to noise in the workplace leads to serious health problems for employees. Constant air conditioning noise raises blood pressure and increases the risk of cardiovascular diseases. Sleep disturbances caused by excessive noise reduce the body’s regeneration during nighttime rest. Employees exposed to noise above 45 dB more frequently report headaches and short-term memory problems. Long-term exposure leads to permanent hearing loss even at levels considered safe. Investing in professional acoustic insulation of ventilation systems protects the health of the team and reduces sick leave.

Employers investing in improving office acoustics achieve measurable economic benefits beyond increased productivity. Attractive working conditions help retain valuable employees and reduce staff turnover. Recruiting new specialists becomes easier when the company offers a comfortable environment without excessive noise. Environmental certifications for office buildings, such as BREEAM or LEED, require compliance with acoustic standards. Properties meeting high acoustic standards achieve higher rental rates and market value. The cost of insulating HVAC systems pays off through increased employee efficiency within 18 to 24 months.

Compliance with Acoustic Standards for Commercial Buildings

Building regulations strictly define maximum allowable noise levels in various types of rooms. Residential rooms must not exceed levels from 30 to 35 dB at night. Offices and conference rooms should maintain levels between 35 and 40 dB. Technical installations must mandatorily meet strict acoustic requirements.

Regular sound level measurements verify actual compliance with applicable acoustic standards. Detected limit exceedances absolutely require additional acoustic insulation. Modernization of existing air conditioning installations often becomes necessary. Sound-absorbing materials available from ABM Insulation effectively help achieve the required parameters.

International environmental building certifications consider acoustic parameters as evaluation criteria. The BREEAM and LEED assessment systems clearly reward low noise levels in rooms. Investments in professional acoustic insulation significantly increase the market value of properties. Buyers and tenants increasingly pay special attention to acoustic comfort.

Energy Savings through Improved Thermal Efficiency

Effective thermal insulation of refrigeration pipes significantly reduces energy losses in the system. Unprotected pipelines cause system efficiency drops ranging from 15 to 25 percent. Compensating for losses requires increased compressor power and longer operating times. Higher electricity consumption directly raises monthly operating costs.

Thermal insulation foams characterized by a closed-cell structure minimize heat exchange with the environment to the maximum extent. Properly executed refrigeration system insulation reduces electricity consumption by 10 to 20 percent. Real financial savings repay the total cost of insulation materials within just 2 to 3 years. Long-term economic benefits far exceed initial investment outlays.

Economic benefits of thermal insulation:

- Reduction of monthly electricity bills by 10 to 20 percent

- Payback period for materials ranging from 2 to 4 years

- Extension of compressor lifespan by reducing load

- More stable system operation without abrupt cycling

- Higher property value due to lower operating costs

Air conditioning systems equipped with effective thermal insulation require lower installed power of refrigeration compressors. Investors can choose units with lower electrical power, which reduces the cost of purchasing equipment. Smaller compressors consume less energy and generate lower noise levels during standard operation. Pipe insulation eliminates the need for power reserves compensating for thermal losses in the installation. Buildings with well-insulated HVAC systems receive higher energy efficiency ratings in certificates. Lower electricity consumption reduces carbon dioxide emissions, supporting climate goals of businesses and public institutions.

Durability of foams under variable air humidity conditions

Insulation materials must absolutely maintain their properties throughout the long service life of the system. Air humidity varies significantly depending on the season and weather conditions. Open-cell foams can absorb moisture, systematically losing their effectiveness. Closed-cell structures remain completely resistant to moisture.

Rubber foam available in the ABM Insulation offer is characterized by full waterproofing throughout years of use. A water absorption rate below 1 percent by volume ensures long-lasting material durability. The material does not degrade under cyclic freezing and thawing. Dimensional stability of rubber foam is maintained for over 15 years of intensive use.

High resistance to ultraviolet radiation effectively protects the outer layers of insulation. Materials resistant to ozone exposure retain full elasticity for a very long time. The neutral pH of rubber foams prevents electrochemical corrosion of metal pipes. Comprehensive protection of all installation components significantly extends the lifespan of the entire air conditioning system.

Tip: Regular visual inspection of the insulation layer every 3 to 5 years allows early detection of possible mechanical damage and enables local repairs before more serious problems develop.

FAQ: Frequently Asked Questions

What thickness of acoustic foam should be chosen to soundproof an air conditioning system?

The choice of foam thickness directly depends on the frequency of noise generated by the installation. Thinner layers from 10 to 15 mm effectively dampen high frequencies, such as air noise. Medium thickness from 20 to 30 mm reduces a wide range of sounds. Thicker foams from 40 to 50 mm eliminate low tones emitted by compressors.

Ventilation ducts require foam with a minimum thickness of 20 mm. The enclosures of outdoor units need a layer from 30 to 40 mm. Freon pipes are insulated with foam from 13 to 19 mm. Ventilation grilles require only a thin layer of about 10 mm. ABM Insulation offers foams in various thicknesses tailored to specific applications.

Does acoustic foam improve the energy efficiency of air conditioning?

Foams combining acoustic and thermal insulation properties significantly reduce energy consumption by the cooling system. Insulating freon pipes reduces heat loss by 15 to 25 percent. The closed-cell structure blocks heat exchange between the pipes and the surroundings. The system operates for shorter periods, reaching the set temperature faster.

Energy characteristics of the improved installation:

- Reduction of electricity consumption by 10 to 20 percent monthly

- More stable compressor operation without abrupt start-stop cycles

- Elimination of moisture condensation on cold pipe surfaces

- Extended lifespan of mechanical system components

Insulation of ventilation ducts maintains a constant temperature of supplied air. Materials from ABM Insulation guarantee long-lasting thermal protection of ducts.

Where in the air conditioning installation should sound-absorbing foams be applied?

Strategic placement of insulation materials determines the effectiveness of noise reduction in rooms. Ventilation ducts behind indoor units are a priority application point. Metal enclosures of air conditioners require lining with butyl mats and foam. Refrigerant pipes must be completely wrapped with thermoacoustic insulation. Ventilation grilles need a thin layer of absorbing material directly behind the louvers.

Installation passage points through walls act as structural sound amplifiers. Pipe mounts require flexible pads that break acoustic bridges. Outdoor units need their enclosure interiors lined with anti-resonance material. Condensers and evaporators generate vibrations that require damping. Comprehensive insulation of all elements ensures maximum noise reduction effect for the system.

How long do acoustic foams maintain effectiveness under variable humidity conditions in air conditioning?

The durability of insulation materials mainly depends on cell structure type and moisture resistance. Closed-cell foams, such as rubber-based ones, remain waterproof for over 15 years of use. A water absorption rate below 1 percent provides full protection against degradation. Open-cell materials may absorb moisture, gradually losing acoustic properties.

Foams from ABM Insulation feature full resistance to cyclic changes in air humidity. The closed structure blocks water vapor penetration into the material’s interior. Dimensional stability is maintained even under extreme temperature fluctuations. Neutral pH foam prevents corrosion of metal installation components. Aluminum foil on the surface further increases the vapor barrier properties of the entire insulation layer.

Does installing acoustic foams in air conditioning systems require professional technical knowledge?

Applying sound-absorbing materials to accessible installation components does not require specialized construction skills. Foams with a self-adhesive layer are attached directly to cleaned metal or plastic surfaces. Lining the interiors of outdoor unit enclosures can be done independently after disconnecting the power supply. Wrapping pipes with tubular insulation only requires precise length measurement and sealing joints with tape.

Tasks requiring professional assistance:

- Insulating ventilation ducts inside ceiling enclosures

- Applying foam on high-pressure refrigerant pipes

- Installing acoustic silencers in long duct runs

- Modifying outdoor unit mounts for anti-vibration pads

Simpler tasks, such as lining enclosures or insulating grilles, can be done independently. Interfering with the refrigerant circuit requires service qualifications. ABM Insulation provides materials ready for quick installation without specialized tools.

Summary

Acoustic foams are an absolutely essential component of professional air conditioning installations in modern buildings of various purposes. Effective noise level reduction significantly improves residents’ comfort and working conditions. High-quality materials available from ABM Insulation perfectly combine acoustic properties with thermal insulation. A comprehensive approach to insulating all HVAC system components brings long-term economic benefits.

Precise identification of main noise sources allows optimal application of appropriate insulation materials. Ventilation ducts, refrigerant pipes, and unit enclosures require different specialized technical solutions. Polyurethane foams effectively absorb airborne noise, while rubber foams excellently dampen structural vibrations. Strategic placement of insulation maximizes acoustic efficiency with optimal financial outlays.

The long-term effects of investing in professional acoustic insulation far exceed initial material costs. Lower electricity consumption, compliance with standards, and higher market value of the property are key benefits. The high durability of materials offered by ABM Insulation guarantees maintaining full parameters for many years. Professional acoustic and thermal insulation of air conditioning systems is a wise investment in residents’ health and comfort.

Sources:

- https://www.sciencedirect.com/science/article/abs/pii/S2352710225020078

- https://onlinelibrary.wiley.com/doi/full/10.1002/adem.202300419

- https://www.online-pdh.com/pluginfile.php/79473/mod_resource/content/1/HVAC%20Systems%20Noise%20and%20Vibration%20Control%20Principles.pdf

- https://mepacademy.com/hvac-noise-problems-heres-how-to-identify-and-fix-them-fast/

- https://www.ny-engineers.com/blog/troubleshooting-vibration-and-noise-in-hvac-systems

- https://www.techniconacoustics.com/blog/how-does-foam-absorb-sound/