Choosing the right soundproofing material is a key element of any acoustic insulation project. The market offers a wide range of solutions, from traditional foams to modern composites. Each material has different properties and applications.

Butyl mats are gaining increasing recognition among professionals and end users. Their unique physical and chemical properties translate into exceptional effectiveness in noise reduction. Flexibility, adhesion, and resistance to external factors distinguish them from competing solutions.

A comparative analysis of various soundproofing materials reveals significant differences in efficiency and durability. Butyl mats offer an optimal combination of all key parameters. Their use provides long-lasting benefits in diverse environments and operating conditions.

Comparison of Sound Damping Effectiveness of Different Materials

The effectiveness of sound damping depends on many physical and chemical factors. Different materials exhibit varying abilities to absorb and reflect acoustic waves. Density, flexibility, and internal structure determine the final insulating properties of each solution.

Traditional insulating materials often focus on one aspect of noise reduction. Polyurethane foams effectively absorb high frequencies but perform poorly with low-frequency vibrations. Mineral wool provides good thermal insulation, but its acoustic properties remain limited.

Characteristics of Traditional Materials

Acoustic foams feature a porous structure that effectively absorbs sound waves. Their main advantages are low specific weight and ease of processing. However, susceptibility to moisture and limited durability are significant drawbacks.

Mineral wool offers good insulating properties across a wide frequency spectrum. Its non-combustibility and resistance to high temperatures make it popular in construction. Unfortunately, it requires additional moisture protection and can cause skin irritation.

Rubber mats demonstrate good flexibility and weather resistance. Their dense structure effectively dampens mechanical vibrations. However, limited adhesion and higher weight can complicate installation.

The Advantage of Butyl Mats

Butyl mats combine the best features of various insulating materials. Their unique chemical structure provides exceptional flexibility and adhesion. Butyl is characterized by excellent damping properties across a wide frequency range.

The density of butyl mats translates into effective reduction of low-frequency vibrations. At the same time, their flexible structure absorbs high-frequency waves. The result is comprehensive acoustic protection that surpasses traditional solutions.

Comparison of Damping Effectiveness:

- Butyl mats: 25-35 dB noise reduction

- Polyurethane foams: 15-25 dB noise reduction

- Mineral wool: 20-28 dB noise reduction

- Rubber mats: 18-30 dB noise reduction

Laboratory tests confirm the superiority of butyl mats in most practical applications. Their effectiveness remains stable under various temperature and humidity conditions. Additionally, they exhibit minimal degradation of properties over time.

Advantages of Flexibility and Adhesion of Butyl Mats

Flexibility is a fundamental feature determining the effectiveness of soundproofing materials. The ability to deform under vibrations allows for efficient absorption of acoustic energy. Butyl mats demonstrate exceptional flexibility across a wide temperature range.

The adhesion of the material directly affects the quality of installation and durability. Poor adhesion leads to material detachment and loss of insulating properties. Butyl mats are characterized by excellent adhesion to a variety of surfaces.

Mechanism of Flexibility Action

The elastic structure of butyl mats enables effective damping of mechanical vibrations. The material deforms under acoustic waves, converting sound energy into heat. This process occurs without damaging the material’s structure.

Operating temperature influences the elastic properties of most materials. Butyl mats maintain flexibility from -40°C to +80°C. Stability of properties under extreme conditions is a significant advantage over competing solutions.

Cyclic mechanical loads can lead to material fatigue and loss of elasticity. Butyl is highly resistant to structural fatigue. Long-term use does not cause significant property degradation.

Adhesive Properties

The self-adhesive layer of butyl mats ensures a durable bond with the substrate. A special adhesive activates under pressure, creating a strong molecular bond. The process requires no additional heating or specialized tools.

The variety of substrate materials demands universal adhesive properties. Butyl mats effectively adhere to metal, plastic, wood, and concrete. Adhesion remains stable even with significant temperature fluctuations.

Advantages of Butyl Mats Adhesion:

- Immediate adhesion without the need for reheating

- Durable bond resistant to vibrations

- Versatility for use on various surfaces

- Resistance to detachment in extreme conditions

The quality of the bond affects the effectiveness of the entire insulation system. Loosely adhered material can generate additional vibrations and noise. Excellent adhesion of butyl mats eliminates the risk of such issues.

Tip: Before applying butyl mats, thoroughly clean the surface from dust, grease, and moisture to ensure optimal adhesion and long-lasting insulation effectiveness.

Weather Resistance and Longevity

Weather conditions pose a significant challenge for insulation materials. Temperature fluctuations, humidity, and UV radiation can lead to property degradation. Resistance to external factors determines the long-term effectiveness and cost-efficiency of the investment.

Traditional materials often show limited resistance to extreme conditions. Organic foams decompose under UV and ozone exposure. Metallic materials may corrode in humid environments.

Chemical Stability of Butyl

The chemical structure of butyl provides exceptional resistance to atmospheric factors. The polymer is characterized by low permeability to gases and water vapor. This property protects the material from internal degradation.

Ultraviolet radiation is the main cause of aging in polymer materials. Butyl naturally resists UV without the need for added stabilizers. Prolonged sun exposure does not cause significant loss of properties.

Chemical resistance expands the range of applications for butyl mats. The material does not react with most solvents, oils, and acids. Chemical stability ensures safe use in various environments.

Operational Durability

The lifespan of insulation materials directly affects the total life cycle costs of installations. Frequent material replacement generates additional expenses and downtime. Butyl mats are distinguished by exceptional durability exceeding 20 years.

Accelerated aging tests confirm the stability of butyl mats’ properties. Simulation of 10 years of operation under extreme conditions showed no significant degradation. The material maintains flexibility and adhesion throughout its service life.

Cyclic temperature changes serve as a durability test for construction materials. Butyl mats successfully pass tests from -40°C to +80°C without damage. Dimensional stability remains preserved across the entire temperature range.

Tip: Regular inspection of butyl mats every 2-3 years allows early detection of potential mechanical damage and extends the lifespan of the entire insulation system.

ABM Butyl Mats at ABM Insulation Store

ABM Insulation Store offers a comprehensive range of high-quality butyl mats. The products available feature a variety of thicknesses and formats. Each series has been designed with specific applications and requirements in mind.

ABM Company has specialized in manufacturing insulation materials for many years. Experience and innovative technologies translate into exceptional product quality. All butyl mats come with a 5-year manufacturer’s warranty.

ABM Professional Series

ABM Professional Butyl Mats provide a versatile solution for most applications. Available thicknesses range from 1.5mm to 4mm, allowing customization to specific requirements. The self-adhesive layer ensures easy and quick installation.

The Professional series products feature an optimal quality-to-price ratio. High-quality butyl guarantees effective acoustic and thermal insulation. The flexible structure allows application on curved surfaces.

Available formats include sheets and rolls in various sizes. 50x50cm sheets are ideal for precise applications. Rolls with a width of 1m enable coverage of larger areas without seams.

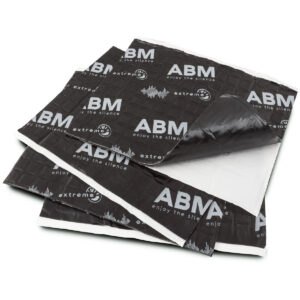

Butyl Soundproofing Mats ABM Professional in the ABM Insulation store

ABM Xtreme Premium Series

ABM Xtreme Butyl Mats represent the highest class of insulation products. Advanced manufacturing technology provides exceptional damping properties. This series is designed for the most demanding applications.

The increased material density results in better insulation effectiveness. A special butyl formulation ensures property stability under extreme conditions. Additionally, an aluminum layer enhances thermal insulation.

Xtreme series products are available in thicknesses from 2mm to 4mm. Each sheet and roll undergoes quality control before shipment. Precise edge processing facilitates installation and ensures an aesthetic appearance.

Butyl Soundproofing Mats ABM Xtreme in the ABM Insulation store

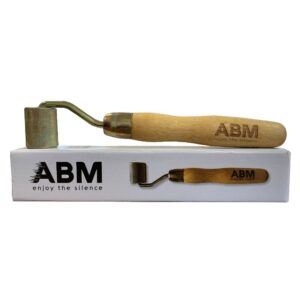

Installation Accessories

Professional installation of butyl mats requires appropriate tools and accessories. The ABM Insulation store offers a complete set of products supporting installation. Each tool has been selected based on the specifics of butyl mats.

Available installation accessories:

- Metal and polyurethane pressure rollers

- Rubber insulating tapes 25mm and 50mm

- Plastic car trim removal kits

- Upholstery knives for precise cutting

- Extraction gasoline for surface cleaning

Metal pressure rollers ensure even pressure distribution during application. Polyurethane alternatives are suitable for delicate surfaces. Rubber tapes seal joints and eliminate acoustic bridges.

Professional tools significantly impact the quality of installation and the final insulation effect. Even pressure application eliminates air bubbles. Precise cutting ensures an exact fit to the shape of the surface.

Accessories in the ABM Insulation store

Ease of Installation and Versatility of Applications

Simplicity of installation is a key factor in choosing insulation materials. Complex installation procedures increase costs and risk of errors. Butyl mats are characterized by exceptional ease of application that does not require specialized training.

The versatility of applications expands the possibilities of using a single material in various projects. The flexibility of butyl mats allows their use in automotive, industrial, and construction sectors. Adaptability to different shapes and surfaces is a significant advantage.

Step-by-step installation process

Surface preparation is the foundation of effective acoustic insulation. Thorough cleaning from dust, grease, and moisture ensures optimal adhesion. The surface temperature should be between 15-25°C for the best results.

Removing the protective film from the adhesive layer begins the actual installation. Gradual peeling during application prevents premature bonding of the material. Even pressure with a roller eliminates air bubbles and ensures full adhesion.

Cutting butyl mats to appropriate dimensions requires sharp tools. An upholstery knife or scissors allow precise fitting to the shape of the surface. Leaving a 2-3mm gap for expansion prevents thermal stress.

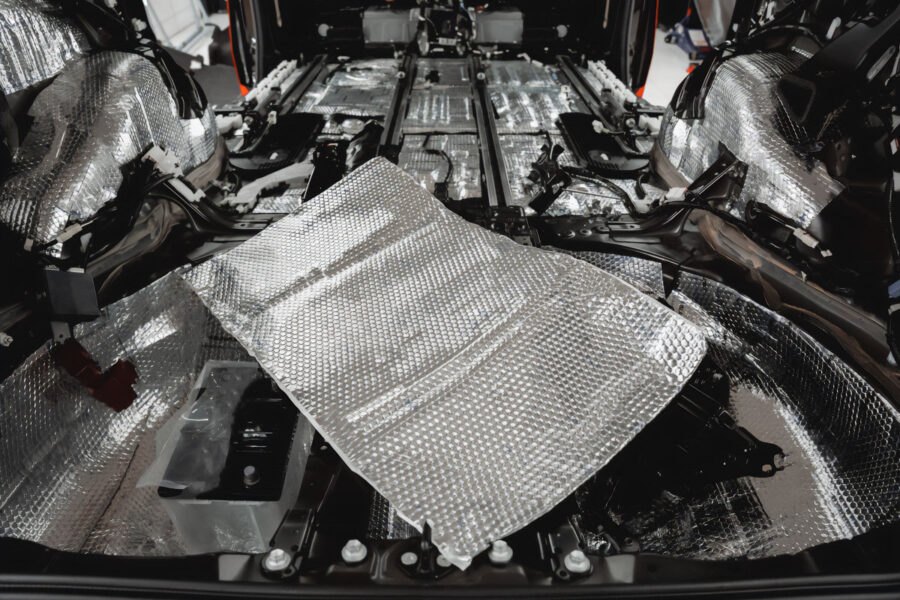

Applications in automotive

The automotive industry is a primary area for butyl mats usage. Noise reduction in vehicles improves driving comfort and market value. Mats effectively dampen vibrations originating from the engine, exhaust system, and tires.

Application in the engine compartment requires materials resistant to high temperatures. Butyl mats maintain properties up to 80°C without degradation. Additionally, they do not emit harmful substances when heated.

Insulating car doors eliminates noises coming from outside. Butyl mats effectively dampen vibrations of windows and panels. The result is a significant improvement in the vehicle interior’s acoustic comfort.

Applications in construction

The construction sector increasingly uses butyl mats for acoustic insulation. Application on ventilation pipes eliminates vibration transmission through installations. Sewer pipe insulation reduces hydraulic noise.

Exterior windows and doors are main sources of noise penetration into buildings. Butyl mats applied to sashes and frames significantly improve acoustic insulation. The material’s flexibility allows maintaining functionality of movable elements.

Mechanical ventilation systems can generate considerable noise during operation. Insulating ducts and equipment with butyl mats effectively reduces sound emission. Moisture resistance ensures long-lasting effectiveness in ventilation environments.

Tip: During installation of butyl mats in vehicles, avoid applying directly on engine parts exceeding 80°C, using additional thermal insulation in high-temperature zones.

The impact of thickness and density on soundproofing efficiency in various materials

The thickness of insulating material directly affects its effectiveness in noise reduction. Increasing thickness improves damping but also increases weight and installation costs. Thickness optimization requires consideration of application specifics and spatial constraints.

The density of the material determines its ability to absorb acoustic energy. Higher density generally translates into better low-frequency vibration damping. However, excessive weight may complicate installation and burden the supporting structure.

Thickness Dependence on Effectiveness

Theoretical acoustics principles indicate a logarithmic relationship between thickness and damping effectiveness. Doubling the material thickness increases insulation by approximately 6 dB. Practical limitations often prevent achieving theoretical values.

Butyl mats with a thickness of 1.5mm provide basic acoustic insulation. Used in applications with low requirements or space constraints. Damping effectiveness is about 20-25 dB depending on frequency.

A thickness of 2.5mm represents a compromise between effectiveness and installation practicality. Universal use in most insulation projects. Improves damping by 3-5 dB compared to the 1.5mm version with a moderate increase in weight.

Mats with a thickness of 4mm are intended for the most demanding applications. Maximum damping effectiveness ranges from 30-35 dB. Increased weight requires reinforcement of the supporting structure in some applications.

The Role of Material Density

The density of butyl mats affects their ability to dampen various sound frequencies. Higher density more effectively reduces low-frequency vibrations originating from engines and machinery. At the same time, maintained flexibility ensures absorption of high frequencies.

| Mat Thickness | Density (kg/m³) | Damping Effectiveness (dB) | Weight (kg/m²) |

|---|---|---|---|

| 1.5mm | 1800 | 20-25 | 2.7 |

| 2.5mm | 1850 | 25-30 | 4.6 |

| 4.0mm | 1900 | 30-35 | 7.6 |

The optimal density for butyl mats is 1800-1900 kg/m³. These values provide effective damping while maintaining material flexibility. Higher density may lead to stiffness and loss of adaptive properties.

A comparison with other materials reveals the advantage of butyl mats in the density-to-effectiveness ratio. Polyurethane foams of similar weight achieve significantly poorer insulation. Mineral wool requires greater thickness for comparable results.

Tip: The choice of butyl mat thickness should consider dominant noise frequencies – for low-frequency vibrations, a minimum thickness of 2.5mm is recommended, while high frequencies are effectively dampened by a 1.5mm layer.

The Versatility of Butyl Mats in Automotive and Construction Applications

The versatility of butyl mats stems from their unique physical and chemical properties. Flexibility, adhesion, and weather resistance enable use in diverse environments. One material can effectively function in both automotive and construction applications.

The adaptability to various shapes and surfaces is a key advantage of butyl mats. The material easily conforms to curved body parts and irregular shapes of building installations. Flexibility is maintained across a wide range of operating temperatures.

Automotive Applications

The automotive industry uses butyl mats for comprehensive acoustic insulation of vehicles. Application on the floor eliminates noise originating from the drivetrain and road surface. Door insulation reduces sound penetration from outside into the cabin.

The engine compartment presents a particularly demanding environment for insulation materials. High temperatures, vibrations, and the presence of oils test the durability of materials. Butyl mats maintain their properties at temperatures up to 80°C without degradation.

Trunks and wheel arches require effective insulation from road noise. Butyl mats applied to these components significantly reduce vibration transmission. The result is a quieter cabin and improved driving comfort.

Delivery and heavy-duty vehicles generate significantly more noise than passenger cars. Larger engines, hydraulic systems, and cargo increase sound emissions. Butyl mats effectively handle intense noise in commercial vehicles.

Construction Applications

The construction sector increasingly appreciates the benefits of butyl mats in acoustic insulation. Ventilation systems transmit vibrations throughout buildings without proper insulation. Applying mats to ducts and equipment eliminates this problem.

Heating and air conditioning systems can generate noise during operation. Heat pumps, chillers, and ventilation units require effective insulation. Butyl mats reduce sound emissions to the surroundings and improve user comfort.

Main areas of application in construction:

- Insulation of ventilation and air conditioning ducts

- Vibration damping of pumps and units

- Noise reduction in hydraulic installations

- Insulation of exterior doors and windows

- Soundproofing technical rooms

Sewer pipes transmit hydraulic noises throughout buildings. Insulating pipes with butyl mats effectively reduces these sounds. Moisture resistance ensures long-lasting effectiveness in sanitary environments.

Exterior doors are a weak point in building acoustic insulation. Applying butyl mats to door panels improves their sound-absorbing properties. The material’s flexibility does not affect the functionality of hinges and locks.

Industry and Special Applications

Industrial machinery generates intense noise during operation. Compressors, generators, and production equipment require effective insulation. Butyl mats reduce sound emissions and improve working conditions.

Power generators installed in residential complexes must meet strict noise standards. Insulating the housing with butyl mats enables achieving required parameters. Weather resistance ensures long-term effectiveness.

Industrial ventilation systems transmit noise over considerable distances. Insulating ducts and equipment with butyl mats protects the environment from excessive sound emissions. Use in manufacturing plants improves working conditions and complies with occupational health and safety standards.

Tip: In industrial applications, consider potential contact of butyl mats with oils and solvents by selecting appropriate thickness and additional chemical protection if necessary.

Summary

Acoustic butyl mats stand out among other soundproofing materials due to their unique combination of properties. Their exceptional flexibility, excellent adhesion, and weather resistance translate into effectiveness surpassing traditional solutions. Comparative analysis confirms the advantage of butyl mats in noise reduction by 25-35 dB.

The versatility of applications makes butyl mats the ideal choice for a wide range of insulation projects. From automotive to construction to industry – one material effectively performs in diverse environments. Ease of installation and long-term durability ensure cost-effectiveness for over 20 years of use.

ABM Professional and ABM Xtreme products available at the ABM Insulation store represent the highest quality butyl mats on the market. A five-year manufacturer’s warranty and a comprehensive range of installation accessories guarantee professional execution of every insulation project.