Butyl mats are a modern solution that ensures quiet and comfort while driving. They effectively dampen noise, vibration and rumble in the car. They are distinguished by their flexibility, durability and resistance to changing conditions.

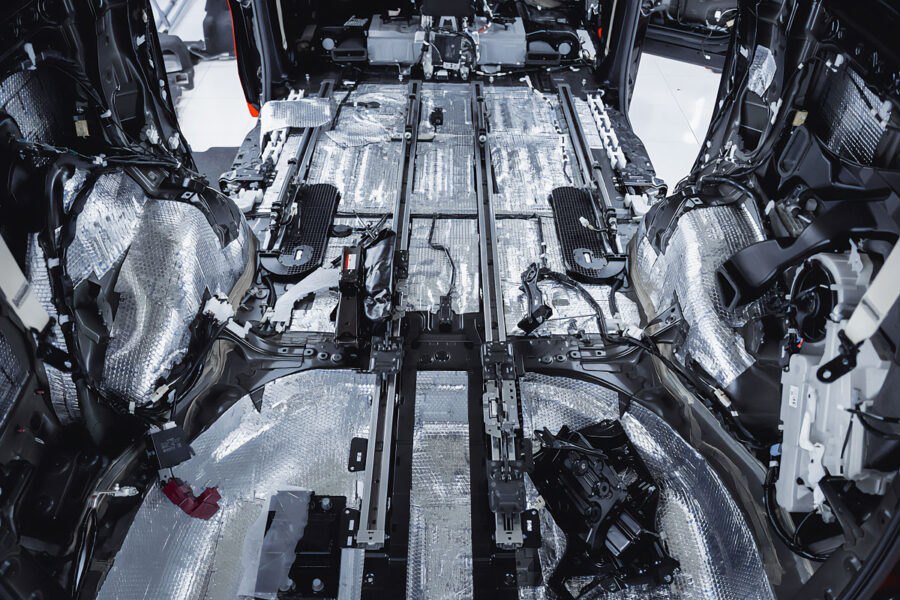

Butyl mats do not need to be heated during installation, which simplifies the installation process. They consist of a butyl and aluminum layer, which form a barrier for sound and heat. They are perfect for soundproofing doors, floors, hoods, trunks and wheel arches. Noise from outside is reduced and the acoustics of the interior are improved.

High-quality butyl mats are resistant to water, oil and mold. They work in a wide temperature range from -50°C to 170°C. Choosing the right mats depends on several key factors affecting the effectiveness of soundproofing and the durability of the installation.

What should I consider when choosing butyl mats for my car?

The selection of butyl mats for soundproofing a car requires the analysis of several important factors. Butyl mats are an effective insulation material for cars, vans, trucks, motorhomes and caravans. They effectively dampen noise and isolate vibrations. The construction of the mats ensures flexibility, which facilitates stretching and shaping without losing damping properties.

Purpose and application

Butyl mats are used in various parts of the car. They can be used in the cabin, the trunk including wheel arches and the tailgate, on the roof of the car, in the doors of the car (service openings, inner sheet metal), on the bonnet of the car and on the floor of the car. Each of these areas requires a different approach to soundproofing.

The car cabin requires special insulation because it is where you spend most of your time. Good sound insulation increases driving comfort and reduces fatigue during long journeys.

The trunk with wheel arches is a place where noise can occur when driving on uneven surfaces. Soundproofing this area eliminates rumbling and knocking, which can be a nuisance when transporting loads.

The roof of a car is a large, flat surface that is easily affected by vibrations. The use of butyl mats on the roof reduces outside noise, including the sound of wind and rain.

Material properties

When choosing butyl sheets, it is worth paying attention to their composition and parameters. The best sheets are made of 100% butyl and aluminum foil. The aluminum layer should be about 0.1 mm (100 microns) thick, which ensures good thermal and acoustic insulation.

Good quality butyl sheets are characterized by:

- effective noise and vibration reduction,

- strong adhesive layer that does not require heating,

- resistance to cracking (no asphalt in the composition),

- resistance to liquids and mold,

- good thermal insulation,

- high flexibility,

- no toxic compounds in the composition.

Butyl rubber mats can be used in temperatures ranging from -40°C to 170°C. They are suitable for use in various climatic conditions. This is particularly important for soundproofing the engine compartment, where high temperatures are generated by the engine.

Tip: When choosing butyl mats, check the composition. Mats containing asphalt or other petroleum-based substances can melt and give off an unpleasant odor at high temperatures.

Installation and practical aspects

Ease of installation is an important factor when choosing butyl sheets. Good sheets have a self-adhesive layer that does not require additional gluing or heating. Installation consists of removing the protective layer and sticking the sheet to a clean, dry and grease-free surface.

The mats can be attached to any metal part and adjusted to the shape of the sheet metal. After applying the mat, it must be pressed down firmly with a roller. For a better soundproofing effect, waterproof foam rubber can be applied on top of the mat.

Amount of material needed to soundproof a car

The amount of material needed depends on the model and type of vehicle.

Approximate quantities for a standard passenger car:

- Front doors (pair): approx. 2 m² butyl mat + 1 m² foam rubber

- Rear doors (pair): approx. 1.5 m² butyl mat + 1 m² foam rubber

- Trunk with wheel arches: approx. 3 m² butyl mat + 3 m² foam rubber

- Floor with engine compartment: approx. 3.5 m² butyl mat + 3.5 m² foam rubber

- Roof: approx. 2 m² butyl mat + 2 m² foam rubber

Butyl mats are available in sheets or rolls. Sheets can be easily cut to size and fit smaller areas. Rolls are suitable for soundproofing large areas such as the floor or roof.

How to recognize high-quality butyl mats?

Recognizing high-quality butyl mats requires analyzing several technical parameters and physical characteristics. There are various products available on the market, but only the best ones ensure effective soundproofing of a car for years. Professional butyl mats are distinguished by specific properties that are worth knowing before buying.

Technical and material specifications

High-quality butyl mats have clearly defined technical parameters. The thickness of the mat is about 2 mm. This is the optimal value, combining soundproofing effectiveness with low weight. Mats that are too thin do not dampen noise well, and those that are too thick increase the weight of the vehicle.

A 0.1 mm (100 micron) thick aluminum layer provides thermal and acoustic insulation. Thinner aluminum does not provide effective protection against heat and sound.

High-quality mats are made of 100% pure butyl combined with aluminum foil. The absence of asphalt in the composition prevents cracking and crumbling at changing temperatures. Good butyl mats remain flexible at temperatures from -40°C to 170°C.

The weight of the mat is an indication of its quality. Professional mats have a high density, which is reflected in their weight. A mat measuring 50 cm x 70 cm x 2 mm should weigh about 1.16 kg net, which gives a density of about 3.3 kg/m².

Physical properties and practical tests

High-quality butyl mats are characterized by an even aluminum surface without bubbles or wrinkles. Real aluminum has a metallic sheen and is scratch-resistant.

Flexibility is an important quality feature. The mat should be flexible but not rubber-like. It should not break or crumble when bent. The butyl layer must be even, without visible bumps or delamination.

The adhesive layer should be evenly distributed and protected with a release paper. After removing the paper, the adhesive should still be sticky but not leave any residue on your fingers. A strong adhesive ensures a permanent bond without the need for heating.

Tip: Before buying a large quantity of butyl sheets, it is worth doing a simple test. Stick a piece of the sheet to a vertical metal surface and leave it there for several hours at different temperatures. A good sheet will not come off or slip even at high temperatures.

Characteristics of professional butyl sheets

Professional butyl sheets can be recognized by

- No unpleasant odor, which indicates harmful substances

- Even cut edges, without fraying or delamination

- Robust packaging to protect against damage

- Clear manufacturer’s markings and technical parameters on the packaging

Certificates and manufacturer’s guarantees

High-quality butyl mats have certificates confirming their technical parameters and safety. Renowned manufacturers subject their products to tests for thermal resistance, moisture and sound attenuation. The certificates include tests for resistance to high and low temperatures, resistance to moisture and mold, and noise and vibration attenuation efficiency.

The manufacturer’s warranty is an additional confirmation of the quality of butyl mats. The best manufacturers offer warranties of up to 5 years, which indicates the durability and effectiveness of their products.

Tip: Before buying butyl mats, it is worth paying attention to the opinions of users and vehicle soundproofing specialists. The experiences of others can provide information about the quality and effectiveness of specific products.

Key technical parameters affecting soundproofing effectiveness

The effectiveness of soundproofing a car depends on several important technical parameters of butyl mats. Knowledge of these parameters makes it easier to choose the material that will provide the best acoustic results. Professional butyl mats are distinguished by precisely defined values, which contributes to their high effectiveness.

Sound and vibration damping coefficient

The acoustic loss factor determines the material’s ability to absorb vibration energy and convert it into heat. This is a key parameter for soundproofing. High-quality butyl mats have a much higher acoustic loss factor than bitumen materials, especially at higher temperatures.

Tests show that butyl mats retain their sound-insulating properties even at 104°C. Bituminous materials, on the other hand, lose their effectiveness at 86°C. In practice, this means that butyl mats effectively soundproof a car even on hot days when the temperature inside the vehicle rises.

The molecular structure of butyl ensures the material’s stability in various weather conditions. Butyl molecules form a dense, regular structure that effectively blocks sound, gas and moisture. The material retains its soundproofing properties for a long time, regardless of the conditions of use.

Density and thickness of the material

The density of the butyl mat directly affects its sound-absorbing capacity. The optimal density is between 2.1 and 4.8 kg/m². Mats with a higher density insulate better, especially in the low-frequency range, which is the most disruptive when driving.

The thickness of the mat also matters. The standard thickness is about 2 mm, which strikes a balance between soundproofing effectiveness and weight. The mats are available in various thicknesses, from 1.3 to 4 mm, which allows for customization.

The weight-to-thickness ratio affects the acoustic properties. Mats that are too thin do not insulate sounds effectively, while those that are too thick unnecessarily increase the weight of the vehicle. Professional butyl mats offer an optimal weight-to-thickness ratio, which allows for effective soundproofing without excessively burdening the vehicle.

Tip: When planning the soundproofing, it is worth using mats of different thicknesses in different places. For the floor and roof, where there are large flat surfaces, it is best to use mats with a thickness of 2-3 mm. For doors and wheel arches, mats with a thickness of 1.5-2 mm are sufficient.

Operating temperature range and resistance to external factors

The operating temperature range is an important parameter for butyl mats, affecting their durability and effectiveness. High-quality mats work in temperatures from -40°C to 170°C. This is important, especially when soundproofing the engine hood, where temperatures can be high.

Resistance to moisture and chemicals is also important. Good butyl mats are resistant to water, oils, fuels and mold. Butyl has low gas and moisture permeability, which prevents corrosion of the sheet metal under the mat.

ABM Insulation butyl mats are distinguished by the following parameters:

- operating temperature range: -40°C to 170°C,

- water and oil resistance,

- no mold or fungus growth,

- flexibility at low temperatures,

- dimensional stability at high temperatures.

The technical parameters of butyl mats directly affect their soundproofing effectiveness. Choosing mats with the right properties can significantly improve the acoustic comfort in a vehicle. Professional butyl mats, such as ABM Insulation products, offer optimal parameters that ensure effective soundproofing for many years.

The advantage of butyl mats over bituminous materials

A comparison of butyl mats and bitumen materials shows significant differences in the effectiveness of soundproofing a car. Butyl mats are a modern solution that eliminates the problems associated with using older bitumen materials. Laboratory tests from March 2025 confirm the superiority of butyl mats in almost every aspect.

Acoustic effectiveness at different temperatures

Butyl mats retain their soundproofing properties across a wider range of temperatures than bituminous materials. Tests have shown that butyl is effective at attenuating sound even at temperatures as high as 104°C. Bituminous materials lose their effectiveness at temperatures as low as 86°C.

The difference in effectiveness is significant. Butyl mats have a 60% higher damping coefficient at 86°C and 72% higher at 104°C.

Bitumen materials soften at high temperatures, which reduces their soundproofing properties. At low temperatures, they become brittle and crack. Butyl mats remain flexible and effective in a range from -50°C to +150°C. This makes them suitable for use in changing climatic conditions.

The molecular structure of butyl allows for better vibration and sound damping. The material absorbs vibration energy and converts it into heat, which significantly reduces noise inside the vehicle. Acoustic tests show that butyl mats can reduce noise levels by 3-7 dB more than similar bituminous materials.

Durability and resistance to external factors

Bituminous materials tend to age and degrade. Over time, they harden, lose elasticity and crack. Cracks allow moisture to penetrate under the mat, which can lead to corrosion of the vehicle body.

Butyl mats do not show such tendencies. They remain flexible and leakproof for many years of use.

Water and oil resistance is another advantage of butyl mats. Bituminous materials can absorb moisture and chemicals, which causes them to degrade. Butyl mats are completely waterproof and resistant to oils, fuels and other chemicals commonly found in automotive environments.

Butyl mats do not mold or rot, even in humid conditions. This is important in areas exposed to water, such as wheel arches or the floor. Bituminous materials can promote the growth of mold and fungi, especially when they absorb moisture.

Tip: When removing old bitumen mats, it is advisable to clean the car body thoroughly before installing the new butyl mats. Bitumen residues can be removed with a citrus solvent, which is effective and safe for the paint.

Easy installation and practical aspects of use

Butyl sheeting is easier and faster to install than bitumen materials. Butyl sheeting does not need to be heated during installation. Simply remove the protective layer and stick the sheeting to a clean surface.

Bitumen materials need to be heated with a heat gun to make them flexible. This makes installation more difficult and increases working time.

The flexibility of butyl mats allows them to be easily adapted to complex car body shapes. The material can be molded and stretched to cover the surface accurately. Bituminous materials are stiffer and more difficult to adjust, which leads to inaccurate coverage of the surfaces to be soundproofed.

Butyl mats are lighter than bitumen materials with a similar damping effect. The lower weight reduces the load on the vehicle, which can have a positive effect on fuel consumption and vehicle performance.

Interesting fact: Butyl mats do not give off the unpleasant odor that often occurs with bitumen materials.

Advantages of butyl mats:

- Installation at lower temperatures,

- Easy removal if necessary,

- Better adhesion to different surfaces,

- No odor typical of bituminous materials.

ABM Insulation butyl mats combine these advantages, offering high-quality soundproofing while remaining easy to install and durable. The advantage over bituminous materials is clear both in technical and practical terms.

Differences between ABM Professional and ABM Xtreme mats

ABM Insulation offers two types of butyl mats: ABM Professional and ABM Xtreme. Both products are used for soundproofing vehicles, but they differ in key features. Knowing these differences makes it easier to choose the right product for your specific needs.

Technical parameters and performance

ABM Professional is a standard butyl mat. It provides good noise, vibration and shock reduction in most automotive applications. It effectively eliminates rumble and noise while driving, which improves acoustic comfort in the vehicle interior.

ABM Xtreme is an improved version of the butyl mat. It offers higher noise reduction efficiency and better thermal insulation. A premium product designed for use in extreme conditions. The ABM Xtreme mat provides higher sound insulation, making it suitable for vehicles with high noise levels.

Tests have shown that the ABM Xtreme mat is better at dampening low-frequency sounds. It effectively absorbs vibration energy and converts it into heat, which reduces noise inside the vehicle. Compared to ABM Professional, the Xtreme version reduces noise levels by an additional 1-3 dB.

Specialized applications

The ABM Professional mat is suitable for most standard applications. It is perfect for soundproofing doors, floors, trunks and roofs in cars and vans. It provides a satisfactory level of noise reduction for most users.

The ABM Xtreme mat is designed for more demanding applications.

It is recommended for:

- sports and luxury cars,

- vehicles with loud engines or exhaust systems,

- motorhomes and caravans where acoustic comfort is important,

- yachts and motorboats,

- industrial applications requiring high damping efficiency.

ABM Xtreme is particularly suitable for areas that are particularly exposed to noise, such as the engine compartment, wheel arches or the engine floor. Thanks to its high temperature resistance (up to 170°C), it is also suitable for soundproofing the engine hood.

Tip: To achieve the best soundproofing effect at a reasonable cost, it is advisable to use ABM Xtreme mats in the areas most exposed to noise (e.g. floor, wheel arches). In other areas of the vehicle, ABM Professional mats can be used.

Structure and physical properties

ABM Professional and ABM Xtreme mats differ in their structure and physical properties. ABM Professional has a standard butyl structure with a 0.1 mm (100 micron) thick aluminum layer. It is flexible and easy to install.

ABM Xtreme has an improved structure with increased density. Despite a similar thickness (approx. 2 mm), it has a higher mass per square meter, which translates into better sound dampening properties. The aluminum layer in the Xtreme mat is of high quality, which guarantees better thermal insulation.

Common features of both mats:

- Flexibility to adapt to different surfaces,

- Strong adhesive layer that does not require heating,

- Resistance to liquids and mold,

- No harmful compounds in the composition.

The ABM Xtreme mat is characterized by greater resistance to extreme conditions and higher material density. It provides better sound absorption, which makes it suitable for people expecting the highest soundproofing quality.

The choice between ABM Professional and ABM Xtreme mats depends on the user’s needs, the type of vehicle and the expected level of soundproofing. Both mats offer high quality and effectiveness, but ABM Xtreme provides better damping performance and durability in harsh conditions.

Comparison of the effectiveness of ABM mats with other solutions

ABM butyl rubber mats stand out from other soundproofing materials available on the market. They effectively reduce noise, vibration and oscillation. Compared to traditional insulation materials, they provide higher efficiency. Analysis of technical parameters and practical applications shows the advantage of ABM mats over the competition.

Acoustic efficiency

ABM butyl rubber mats have a high sound reduction index (SRI) of 0.38. This means that the material is able to absorb vibration energy and convert it into heat. In practice, this effectively reduces noise across a wide range of frequencies.

Tests have shown that ABM mats reduce noise levels by 3-7 dB more than other soundproofing materials. The difference is particularly noticeable with low-frequency sounds, which are the most difficult to eliminate. The soundproofing effect translates into a clear improvement in acoustic comfort in the vehicle.

The structure of ABM mats ensures even noise reduction across the entire frequency range. Other materials often focus on selected ranges, which results in gaps in sound insulation. ABM mats effectively eliminate both airborne noise and structural vibrations transmitted through body parts.

Durability and resistance to external conditions

ABM butyl mats are characterized by durability and resistance to changing weather conditions. The operating temperature range is from -40°C to 170°C. This is much more than other soundproofing materials offer. The stability of properties in such a wide temperature range ensures effective soundproofing regardless of weather conditions.

Resistance to moisture and mold is another advantage of ABM mats. The material does not absorb water or liquids, which prevents degradation of the insulating properties. Other materials, especially those with a porous structure, lose their effectiveness in contact with moisture.

Tip: When choosing a soundproofing material, pay attention not only to the initial effectiveness, but also to durability and resistance to external factors. ABM mats provide long-lasting sound insulation, which reduces vehicle operating costs in the long term.

Easy to install and versatile in application

ABM butyl mats are easy to install compared to other solutions. The self-adhesive layer with high adhesion eliminates the need for additional adhesives. There is no need to heat the material before application. The installation process is quick and does not require specialized tools.

The flexibility of ABM mats allows them to be easily adapted to complex car body shapes. The material can be stretched and molded without losing its damping properties. Other materials, such as bitumen mats or acoustic foams, are often stiffer and more difficult to install on uneven surfaces.

The versatility of ABM mats covers various components of a car as well as other vehicles and industrial applications. The mats are suitable for soundproofing a car cabin, the interior of a motorhome or industrial machinery. This makes ABM mats an economical solution for various soundproofing projects.

ABM butyl mats offer a comprehensive solution to the problem of noise. They combine the functions of sound insulation, thermal insulation and anti-vibration. This eliminates the need for several different materials. This simplifies the soundproofing process and reduces the total cost of the investment.

Long-term benefits of investing in high-quality butyl mats

Investing in high-quality butyl mats for soundproofing your car has many advantages. The effects are noticeable for many years of vehicle use. Professional butyl mats, such as ABM Insulation products, improve acoustic comfort and provide long-term economic and functional benefits. When properly selected and installed, butyl mats permanently reduce noise and vibration in the car.

Durability and resistance to aging

High-quality butyl mats are extremely durable. They maintain their sound-absorbing properties for many years. Butyl material does not degrade over time or under changing weather conditions. Studies show that professional butyl mats retain their technical parameters for 10-15 years. This makes them a one-time investment for the entire service life of the vehicle.

UV resistance is another feature of premium butyl mats. Low-quality products can quickly lose their properties when exposed to the sun. High-quality butyl remains stable even when exposed to sunlight for a long time. This prevents premature aging of the material and its effectiveness remains constant.

Dimensional stability across a wide range of temperatures ensures that the soundproofing properties remain constant regardless of the season. ABM Insulation butyl mats operate at temperatures ranging from -40°C to 170°C. They guarantee effective soundproofing in both cold winter and hot summer. Lower-quality materials can lose their elasticity at low temperatures or soften at high temperatures, which reduces their acoustic properties.

Impact on vehicle value and savings

Soundproofing a car with high-quality butyl mats affects the market value of the vehicle. Cars with good sound insulation are more valued on the second-hand market, which increases the resale price. Automotive industry specialists estimate that a well-soundproofed car can have a 5-10% higher residual value than a similar model without soundproofing.

Butyl mats also improve the thermal insulation of the vehicle interior. Less energy is used to heat or cool the cabin, which results in lower fuel consumption. Savings can be 2-5% per year, especially in extreme weather conditions when air conditioning or heating is used intensively.

The reduction of vibrations and oscillations of the car body reduces wear and tear on the mechanical components of the vehicle. Excessive vibrations can accelerate wear and tear on bearings, shock absorbers and screw connections. Soundproofing with butyl mats reduces these vibrations, thus extending the service life of many vehicle components.

Tip: When selling your car, keep the purchase and installation documentation of high-quality butyl mats. The information about professional soundproofing with ABM Insulation mats can be an important argument during price negotiations.

Improved driving comfort and safety

The long-term benefits of butyl mats also include driving comfort and safety. Reducing noise in the cabin reduces driver fatigue on long journeys. Studies show that noise levels of 70-80 dB, typical for a car interior without soundproofing, can lead to faster fatigue, decreased concentration and longer reaction times.

Premium butyl mats reduce road noise, making it easier to hear warning signals such as emergency vehicle sirens and car horns. This is crucial in situations that require quick reactions on the road.

Vibration reduction improves driving precision. Excessive vibrations transmitted to the steering wheel, pedals or seat can make it difficult to control the car, especially during dynamic driving. Soundproofing with butyl mats eliminates these problems, providing a better feel for the vehicle and greater stability on the road.

Long-term benefits of high-quality butyl mats:

- Maintenance of sound-insulating properties for 10-15 years.

- Increase in the market value of the vehicle by 5-10%.

- Fuel savings of up to 2-5% per year.

- Reduction of fatigue during long journeys.

- Better audibility of warning signals.

- Improved steering precision.

Thanks to their high quality and durability, ABM Insulation butyl mats provide these benefits throughout the vehicle’s service life. They are an investment that pays off in the form of improved driving comfort, economic benefits and increased road safety.

Summary

The choice of butyl mats for soundproofing a car affects the effectiveness of noise suppression. High-quality butyl mats, such as ABM Insulation products, effectively reduce noise, vibration and oscillation, which improves driving comfort.

When choosing mats, pay attention to key technical parameters: thickness, density, quality of the aluminum layer, and operating temperature range. Butyl mats outperform traditional bituminous materials in terms of durability, flexibility, and ease of installation.

The ABM Professional series is suitable for standard applications, while ABM Xtreme offers more effective damping in demanding conditions. Investing in high-quality butyl mats brings long-term benefits: preserving the value of the vehicle, saving fuel and increasing driving safety.

Professional soundproofing of a car with butyl mats not only ensures immediate acoustic comfort, but also long-lasting effects for years to come. Properly selected and installed butyl mats guarantee a quiet, comfortable ride throughout the vehicle’s lifetime. Every trip becomes more pleasant and less tiring.